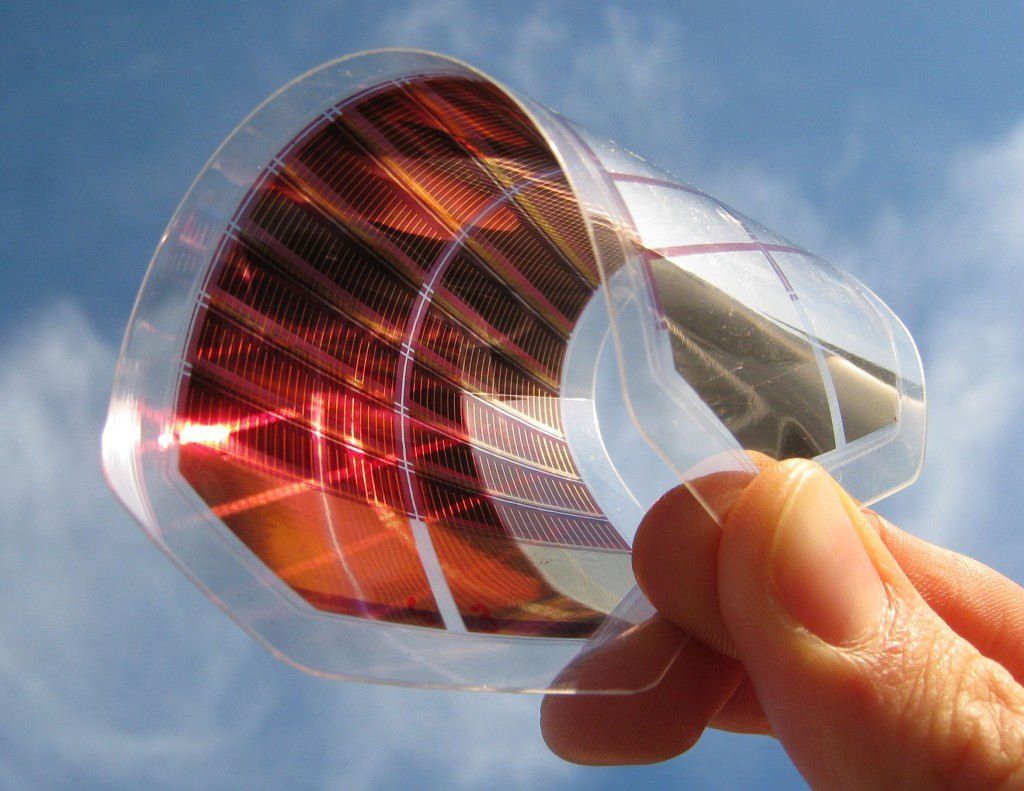

Solar power has been gaining more and more popularity worldwide since the efficiency of solar panels has significantly increased during the recent years, along with the dramatic decrease in the costs. However, its popularity is not only due its affordability to a wider audience but also to the growing awareness about the benefits of clean sources of energy. Yet, the costs of transportation and production often make it extremely difficult to implement solar technology in developing countries. Printed solar cells could offer a solution to this problem.

Thanks to the advances in printed solar cell technology during the past few years, its energy efficiency has increased from 3% to 20%.

“Its success is due to its cost-effectiveness and simplicity. A 10×10 cm solar cell film is enough to generate as much as 10–50 watts per square meter,” said Scott Watkins from the Korean company Kyung-In Synthetic.