Category: 3D printing

3D printing in gel shows how scientists could print human organs

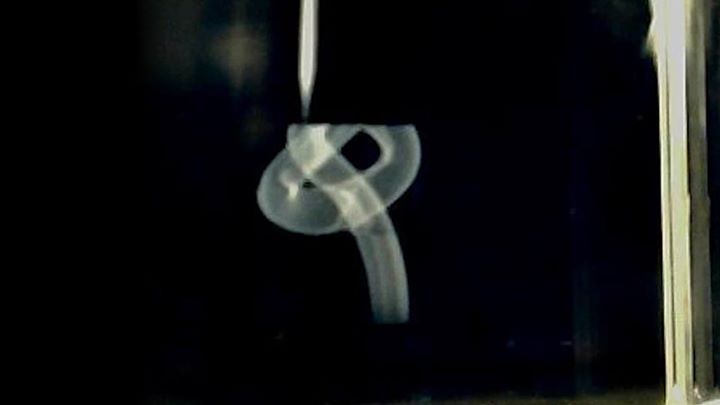

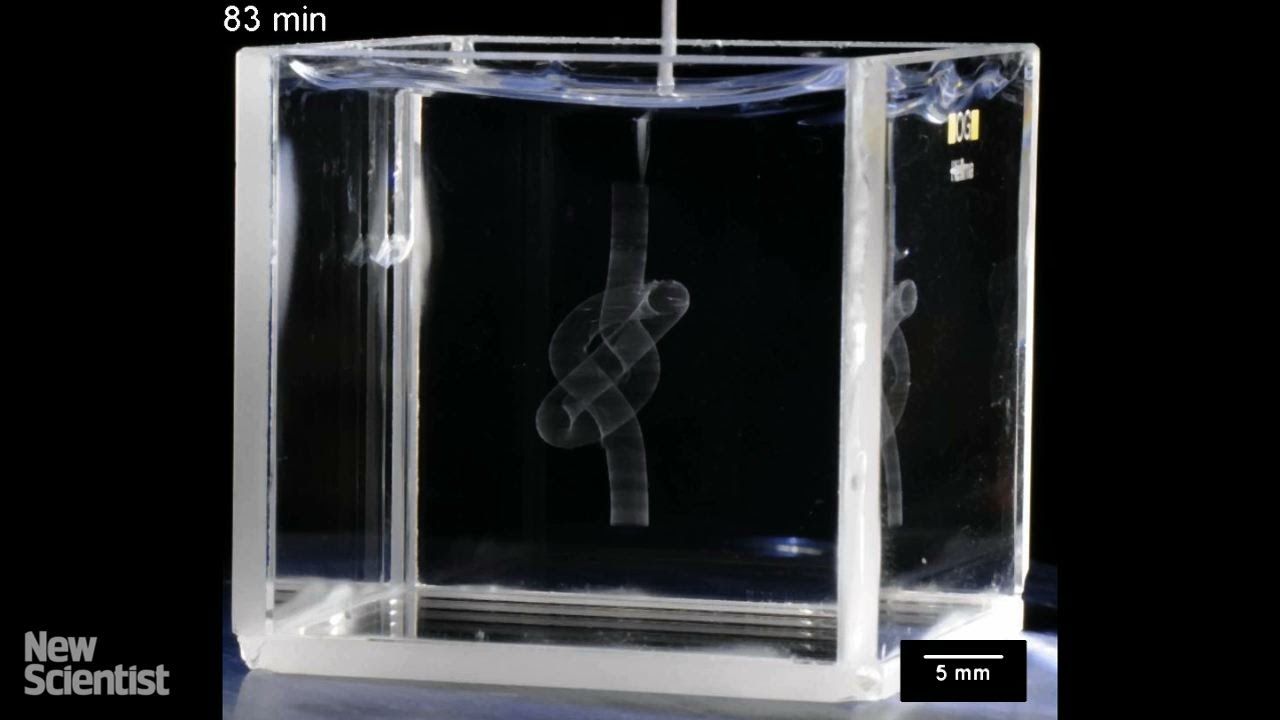

While scientists have had success in the past printing structures like “bionic ears,” a clear path to making functional internal organs and tissue hasn’t really emerged. However, researchers at the University of Florida in Gainesville have developed a way of printing complex objects in gel, a method that could help pave the way to 3D-printed organs in the future.

The hard thing about printing intricate organic structures like blood vessels and complicated organs is that they collapse under their own weight before they solidify. The gel here, which is made of an acrylic acid polymer, acts as a scaffold to hold the structure in place during the printing process. That approach has already allowed the team to print with organic materials — and even make a replica of a human brain.

Printing in gel isn’t an entirely new idea. And, of course, the method isn’t perfect. For one thing, using inorganic gel as a scaffold can’t keep organic tissue alive. For another, printing very small objects could lead to some particles slipping through the material. However, it’s certainly a solid step forward on the way to printing organs for patients in need someday.

Scientists pioneer 3-D-printed drug delivering micro-needles

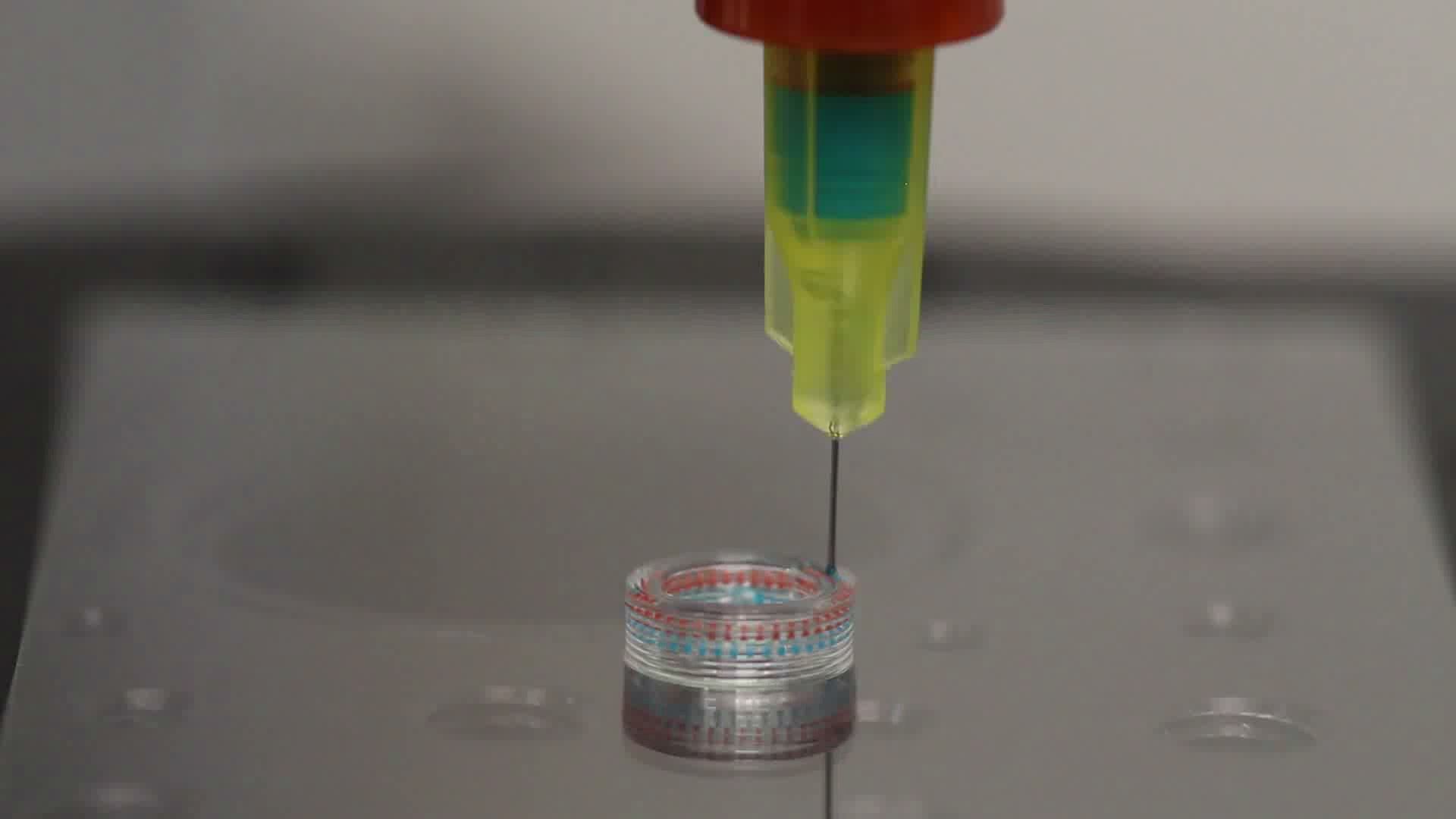

Researchers have developed a new technique to produce a 3D ‘micro-printed’ array of needles capable of drug delivery. The technique would offer a pain-free drug delivery device that would allow drugs to diffuse within the body as the biomaterial device degrades in the body. This offers treatments for a wide range of diseases, including melanoma cancers.

The results are published today, Wednesday 30th September, in the journal Biofabrication .

The researchers, based at the University of Akron and the University of Texas, report producing a drug-loaded array for transdermal delivery of a chemotherapeutic drug, fabricated using microstereolithography. The arrays consisted of 25 poly(propylene fumarate) microneedles, each needle having a tip and base diameter of 20 µm and 200 µm, respectively, and a height of 1 mm.

DNA-guided 3-D printing of human tissue

Reconstituting epithelial (skin) microtissues with programmed size, shape, composition, spatial heterogeneity, and embedding extracellular matrix. Scheme and images of fully embedded aggregates of human luminal and myoepithelial cells. (credit: Michael E Todhunter et al./Nature Methods)

A new technique developed by UCSF scientists for building organoids (tiny models of human tissues) more precisely turns human cells into the biological equivalent of LEGO bricks. Called DNA Programmed Assembly of Cells (DPAC), it allows researchers in hours to create arrays of thousands of custom-designed organoids, such as models of human mammary glands containing several hundred cells each.

3D printed scaffolds allow for precise release of biomolecules into the human body

Just days ago it was announced that a 3D printed guide developed by researchers in Minnesota could help facilitate the regrowth of damaged nerves within the human body. In the wake of this exciting breakthrough, is another progressive use for 3D printing within the medical world, as the same researchers have found a way to release biomolecules into the body through a 3D printed scaffold with more precision than ever before.

The 3D printed scaffolds were developed by Michael McAlpine, an associate professor of Mechanical Engineering at the University of Minnesota, and were funded in part by the NIBIB (National Institute of Biomedical Imaging and Bioengineering).

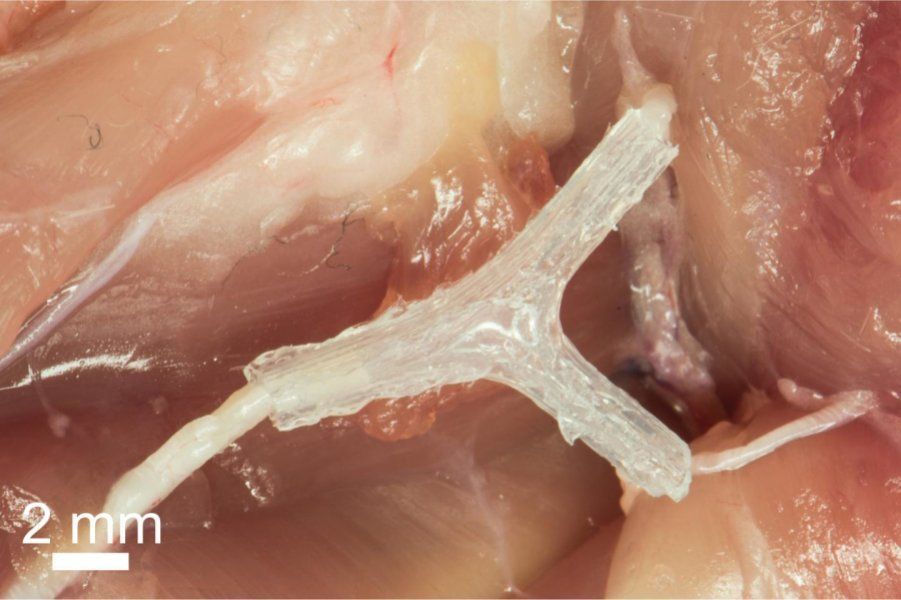

Breakthrough medical discovery: 3D printing might be used to regenerate nerves

Having significantly damaged nerve tissue is bad for a lot of reasons because it doesn’t regenerate easily and it can lead to various serious medical conditions including paralysis. But many scientists are already studying ways of fixing this issue, and a team of researchers from the University of Minnesota, Virginia Tech, University of Maryland, Princeton University, and Johns Hopkins University has figured out how to use 3D printing for nerve growth.

DON’T MISS: 85 legitimate iPhone apps that were infected with malware in the big App Store hack

The technology they’ve developer has allowed them to regrow nerve tissue in lab rats and restore normal walking ability 10 to 12 weeks after the 3D printed guide was implanted.

Open Source ‘Solar Pocket Factory’ Can 3D Print a Solar Panel Every 15 Seconds

Shawn Frayne and Alex Hornstein, two young inventors based in the Philippines, are taking their passion for clean free energy and developing a way to make it accessible and cheap for everyone. These guys are working restlessly to provide a product that could be used by practically anyone to make homemade solar panels.

The factory is small enough to fit on a desktop and efficient enough to produce 300k to one million panels per year, up to one every 15 seconds. By cutting out much of the labor intensive process, which represents 50% of the total cost, this machine can dramatically reduce the price of solar. Their pocket solar panel producer can change the way the world views electricity. Image credit: YouTube/SciFri

What type of applications can a homemade solar panel have? For starters it can replace the need for outlets in a home for smaller electronics such as phones, computers, lamps, etc. One of the more intriguing applications is the added versatility solar panels can provide. In short, with these panels you can use your electronics anywhere there’s sunshine.

New ‘shape-shifting’ material can reconstruct faces

Called a shape-memory polymer (SMP) and developed by a team at Texas A&M University in the US, this biodegradable material can be used to fill in gaps in a damaged face and act as a scaffold to guide the growth of existing bones.

The researchers made their shape-memory polymer by linking molecules of another material — polycaprolactone, or PCL — and whipping it into a foam. According to Jackie Hong at Motherboard, the material is soft and easy to mould when heated to 60°C (140°F), and sets when it’s cooled to body temperature without becoming brittle. It can be used in 3D printing and moulding, which means it can be shaped into extremely precise models and bone scaffolds, and it’s full of tiny holes like a sponge, which allows bone-producing cells called osteoblasts to collect inside and grow.

According to Hong, the researchers enhanced this osteoblast-growing effect by coating their SMP material in polydopamine — a different kind of polymer substance that helps bind existing bones to the SMP scaffold, and has been shown in previous studies to encourage the growth of osteoblasts. Over a three-day trial, their coated SMP scaffold grew five times more osteoblasts than their uncoated scaffold.

World’s largest delta-style 3D printer can print nearly zero-cost housing out of mud

The future of affordable (and sustainable) housing may lie with 3D printing. The World’s Advanced Saving Project (WASP) will soon unveil the world’s largest delta-style 3D printer that can build full-size buildings out of mud and clay for nearly zero cost. The massive 12-meter-tall (40 feet) BigDelta printer will make its official debut and show off its eco-friendly printing prowess tomorrow at “Reality of dream,” a three-day event in Massa Lombarda, Italy.

System can convert MRI heart scans into 3D-printed, physical models in a few hours

Researchers at MIT and Boston Children’s Hospital have developed a system that can take MRI scans of a patient’s heart and, in a matter of hours, convert them into a tangible, physical model that surgeons can use to plan surgery.

The models could provide a more intuitive way for surgeons to assess and prepare for the anatomical idiosyncrasies of individual patients. “Our collaborators are convinced that this will make a difference,” says Polina Golland, a professor of electrical engineering and computer science at MIT, who led the project. “The phrase I heard is that ‘surgeons see with their hands,’ that the perception is in the touch.”

This fall, seven cardiac surgeons at Boston Children’s Hospital will participate in a study intended to evaluate the models’ usefulness.