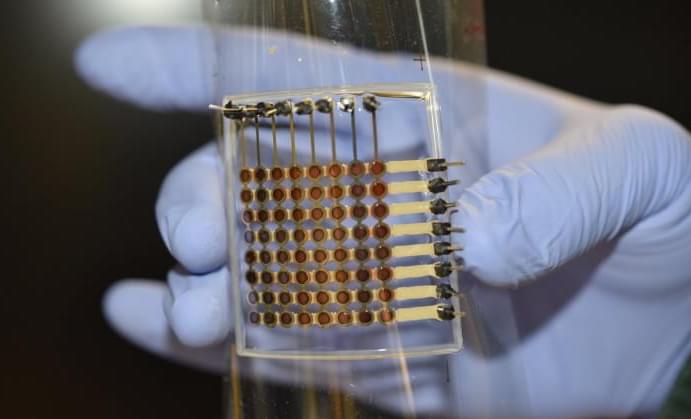

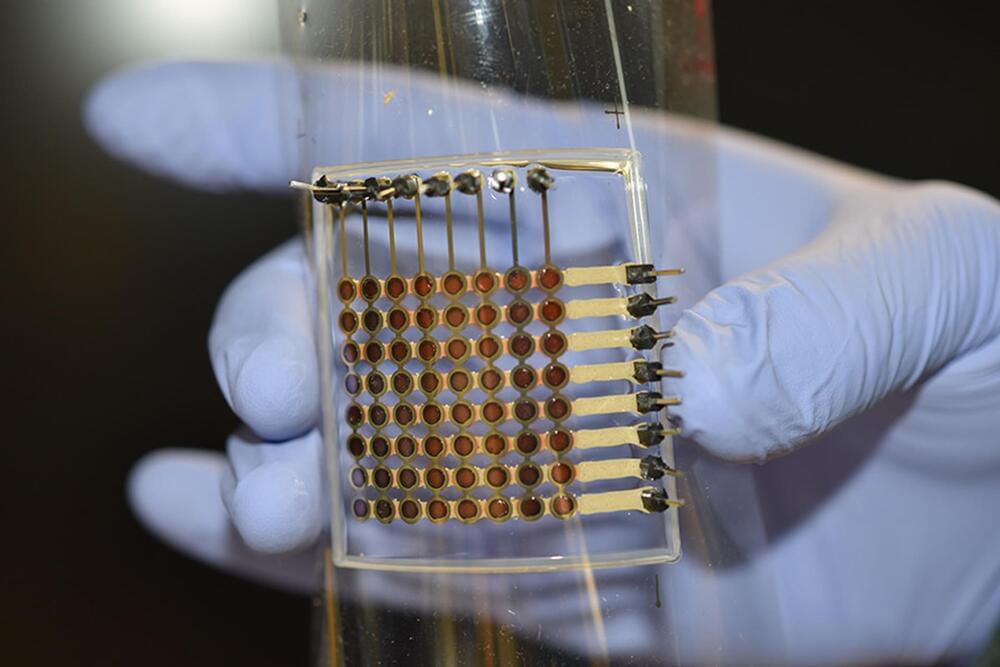

You might not have to send your devices in (or buy replacement parts) if the display breaks — you could just make new screens yourself. University of Minnesota Twin Cities researchers have developed what they say is the first fully 3D-printed flexible OLED display. In theory, you wouldn’t have to depend on panels made at large, distant factories to build or repair your gadgets.

The new approach combines two methods of 3D printing to print the six layers needed for a functional display. The team used extrusion printing to make the electrodes, encapsulation, insulation and interconnects, while active layers were spray-painted at room temperature. Past attempts by various teams either had issues with light uniformity (consistency across the whole panel) or relied on techniques beyond 3D printing to put some components in place, such as spin-coating or thermal evaporation.

The prototype was just 1.5 inches wide and used just 64 pixels. Any practical uses would require much higher resolutions (a 1080p display requires over 2 million pixels), and the scientists also want to improve brightness. It might also take a while to adapt the technology for home use. The university used a custom 3D printer that costs as much as a Tesla Model S — it might take a while for the method to be viable on off-the-shelf printers, even including high-end models like FormLabs’ $4,850 3B+.