CHINA’S NEW THORIUM-BASED NUCLEAR REACTOR is well situated for being adopted for Space applications.

China is slowly but steadily positioning itself to leap ahead of the US Space program. It is doing this without pomp and fanfare, and without the idea of a “space race,” simply based upon what it requires for its future.

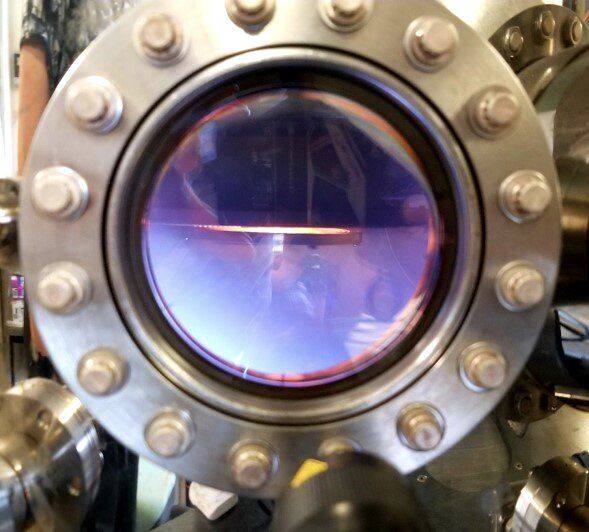

1) Recent noteworthy progress on molten salt thorium reactors could be a key component of future Chinese space-worthiness. Originally designed by the USA’s Oak Ridge National Laboratory in the 1960’s, they were planned to be used for nuclear powered strategic bomber planes, before the nuclear submarine concept became adopted as more feasible. They were chosen because they can be miniaturized to the size of an aircraft. By the same token, they could conceivably be used in advanced atmospheric or space propulsion.

2) Recently, China announced successful tests on a new type of aircraft that takes in air from the surrounding atmosphere, ionizes it with electricity, and expels it as exhaust. The only thing needed would be a strong enough on-board electrical supply to supply the huge amount of power required. Only a nuclear power plant could supply that power unless it were to be beamed from ground stations. Such a plane would require no fuel for its entire lifetime. It could also function in any atmosphere, not only Earth’s atmosphere, since it is not based on burning fuel chemically, which requires oxygen. Versions of such air-plasma-breathing thrust could be used as part of the boosting phase of a rocket launch system.

3) A few days ago, China tested part of its fully reusable space plane, which is a vastly superior system to SpaceX’s “Starship” rocket. While Starship uses old-fashioned ballistic rocket technology, the Chinese spaceplane, according to reports that have come out, involves something similar to the Sanger space plane design. An early version of the Space Shuttle design also had this configuration. Instead of the Space Shuttle’s dangerous solid rocket boosters on the side, and its external fuel tank, which is dumped once the fuel is used up, such systems have a second “booster aircraft” which glides to a runway after boosting the upper stage orbiter into its atmospheric launch position. So, there are two vehicles which land on a runway, with only the orbiter going into space. In addition to this, the Chinese are adding “combined cycle” technologies, where more than one type of propulsion is being used on the aircraft. So, perhaps turbojets, and scramjets, and rocket engines will be used as one example of such a configuration.

The new molten salt reactors, part of a program developed under the leadership of former Chinese President Zemin’s son, and with collaboration from the US’s Oakridge National Laboratory, is now close to implementation stage. Such reactors could be integrated into a space plane, allowing “single-stage-to-orbit” concepts to become within reach. Such systems would not need a booster phase, but would use a combination of air-plasma-breathing and rocket engines to get to orbit with only a single vehicle, while landing like the Space Shuttle did or perhaps landing with powered flight instead of gliding without fuel as did the Shuttle.

All of this makes China’s plan for “nuclear-powered space shuttles” in the 2040’s very possible. If fusion power is obtained before then, this will all proceed even faster, and all the technical and engineering skills will be immediately brought to bear.

The thorium-powered reactors do not need water as a coolant, meaning they can be built in remote deserts alongside wind and solar power plants.