Scientists have found a rapid way of producing magnesite, a mineral which stores carbon dioxide. If this can be developed to an industrial scale, it opens the door to removing CO2 from the atmosphere for long-term storage, thus countering the global warming effect of atmospheric CO2. This work is presented at the Goldschmidt conference in Boston.

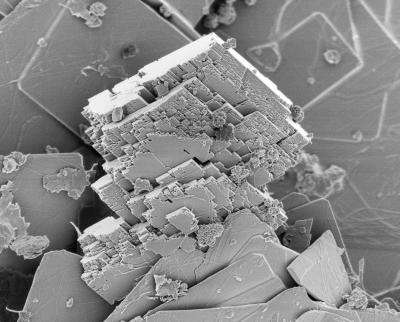

Scientists are already working to slow global warming by removing carbon dioxide from the atmosphere, but there are serious practical and economic limits on developing the technology. Now, for the first time, researchers have explained how magnesite forms at low temperature, and offered a route to dramatically accelerating its crystallization. A tonne of naturally-occurring magnesite can remove around half a tonne of CO2 from the atmosphere, but the rate of formation is very slow.

Project leader, Professor Ian Power (Trent University, Ontario, Canada) said: