Astrophysicist Neil deGrasse Tyson says lawmakers and the media cherry pick scientific papers to reinforce political ideals on climate change and says it’s irresponsible to create public policy while ignoring the scientific community’s consensus.

Astrophysicist Neil deGrasse Tyson says lawmakers and the media cherry pick scientific papers to reinforce political ideals on climate change and says it’s irresponsible to create public policy while ignoring the scientific community’s consensus.

Despite its remaining mystery, the ocean is a complex working environment, widely used for fishing, shipping and recreation; but so far largely untapped for energy generation. OCEANERA-NET seeks to give the industry the boost it needs.

The European Union coastline runs to around 66 000 kilometres. This vast stretch holds a largely unexploited potential for ocean generated electricity, calculated to be around 380 GW by DG MARE (the EU Directorate responsible), constituting a significant contribution to the EU’s 2020 targets for renewable energy.

Presently, there are a number of Member States funding research and development into ocean energy technology. However, these efforts are not coordinated and so not the game-changers they could be.

The energy-generating potential of solar panels – and a key limitation on their use – is a result of what they’re made of. Panels made of silicon are declining in price such that in some locations they can provide electricity that costs about the same as power from fossil fuels like coal and natural gas. But silicon solar panels are also bulky, rigid and brittle, so they can’t be used just anywhere.

In many parts of the world that don’t have regular electricity, solar panels could provide reading light after dark and energy to pump drinking water, help power small household or village-based businesses or even serve emergency shelters and refugee encampments. But the mechanical fragility, heaviness and transportation difficulties of silicon solar panels suggest that silicon may not be ideal.

Building on others’ work, my research group is working to develop flexible solar panels, which would be as efficient as a silicon panel, but would be thin, lightweight and bendable. This sort of device, which we call a “solar tarp,” could be spread out to the size of a room and generate electricity from the sun, and it could be balled up to be the size of a grapefruit and stuffed in a backpack as many as 1,000 times without breaking. While there has been some effort to make organic solar cells more flexible simply by making them ultra-thin, real durability requires a molecular structure that makes the solar panels stretchable and tough.

New solar energy research from Arizona State University demonstrates that silicon-based, tandem photovoltaic modules, which convert sunlight to electricity with higher efficiency than present modules, will become increasingly attractive in the U.S.

A paper that explores the costs vs. enhanced efficiency of a new solar technology, titled “Techno-economic viability of silicon-based, tandem photovoltaic modules in the United States,” appears in Nature Energy this week. The paper is authored by ASU Fulton Schools of Engineering, Assistant Research Professor Zhengshan J. Yu, Graduate Student Joe V. Carpenter and Assistant Professor Zachary Holman.

The Department of Energy’s SunShot Initiative was launched in 2011 with a goal of making solar cost-competitive with conventional energy sources by 2020. The program attained its goal of $0.06 per kilowatt-hour three years early and a new target of $0.03 per kilowatt-hour by 2030 has been set. Increasing the efficiency of photovoltaic modules is one route to reducing the cost of the solar electricity to this new target. If reached, the goal is expected to triple the amount of solar installed in the U.S. in 2030 compared to the business-as-usual scenario.

With more than 5.6 million articles, Wikipedia is an invaluable resource, whether you’re throwing a term paper together at the last minute, or doing legal research on whether it can really be considered assault if your victim habitually made the “cows outstanding in their field” joke. We explore some of Wikipedia’s oddities in our 5,690,195-week series, Wiki Wormhole.

This week’s entry: Vertical farming

What it’s about: Ah, the farmer’s life. The smell of the soil, the green of the leaves, the view from the 45th floor. Yes, like bathrooms before them, farms are moving into the future by moving indoors. Hydroponic farming has made vertical farms possible, in which floor after floor of a building is devoted to growing food. One such farm in Buffalo, New York contains 17 million plans, and a “windowless farm” in Kyoto produces 6 million heads of lettuce a year.

Tesla is cutting back on plastic with its new car delivery system. On Monday, CEO Elon Musk shared the story of how he personally delivered a Tesla Model 3 to Devin Scott in Los Angeles, using a new method where instead of arriving in plastic wrap, the car is delivered with an enclosed trailer directly from factory to home.

The new method is a marked change from the previous process, where several cars would ship out on a truck to a delivery hub and move out later. It means less packaging, and potentially fewer steps in getting some of the approximately 7,000 cars produced per week into the hands of buyers. Tesla produces around seven times more cars per week than it did when the Model 3 first started production a year ago, and this rapid expansion has led to big changes in the company’s processes to fulfill the 400,000 or so $1,000 reservations for the Model 3. In a March 2017 earnings call, Musk said his goal was to make deliveries “more streamlined, less paperwork, less bureaucracy.”

Closing in on molecular manufacturing…

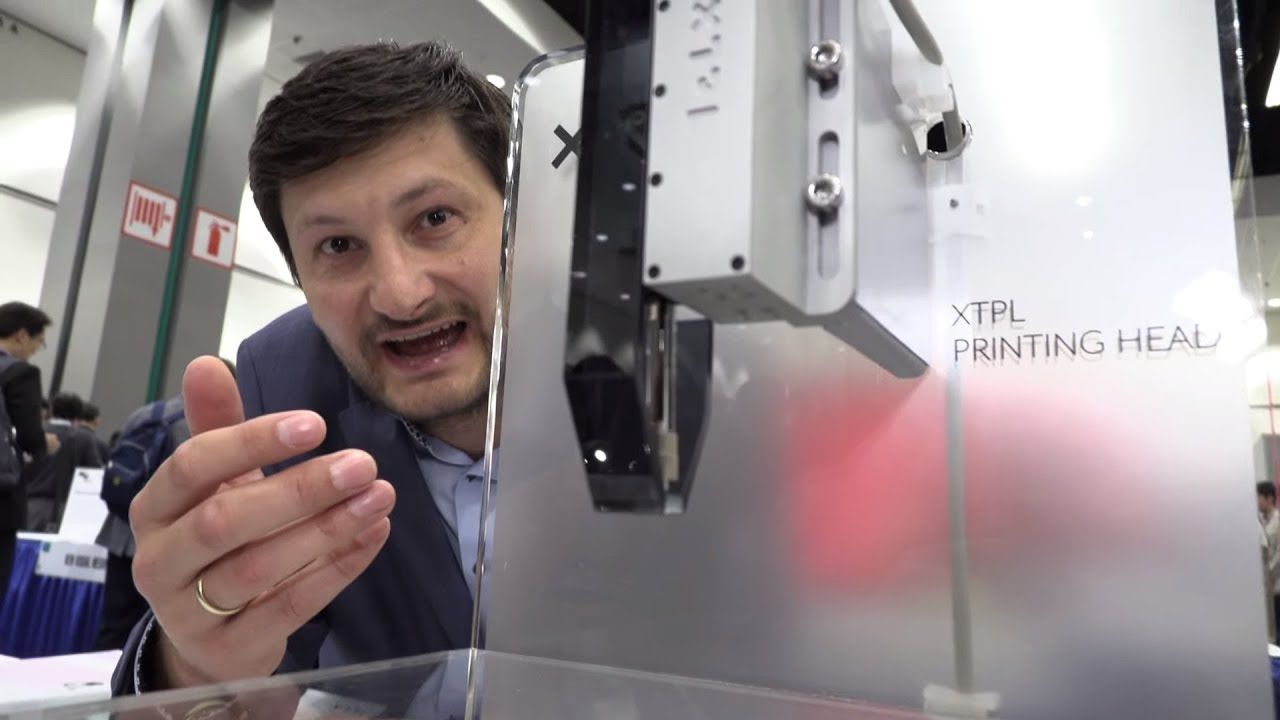

http://xt-pl.com received an honorable mention from I-Zone judges for its innovative product that prints extremely fine film structures using nanomaterials. XTPL’s interdisciplinary team is developing and commercializing an innovative technology that enables ultra-precise printing of electrodes up to several hundred times thinner than a human hair – conducive lines as thin as 100 nm. XTPL is facilitating the production of a new generation of transparent conductive films (TCFs) that are widely used in manufacturing. XTPL’s solution has a potentially disruptive technology in the production of displays, monitors, touchscreens, printed electronics, wearable electronics, smart packaging, automotive, medical devices, photovoltaic cells, biosensors, and anti-counterfeiting. The technology is also applicable to the open-defect repair industry (the repair of broken metallic connections in thin film electronic circuits) and offers cost-effective, non-toxic, flexible industry-adapted solutions.

XTPL’s technology might be the only one in the world offering cost-effective, non-toxic, flexible, industry adapted solution for the market of displays TFT/LCD/OLED, integrated circuits (IC), printed circuit boards (PCB), multichip modules (MCM); photolithographic masks & solar cells market.

XTPL delivers also solutions for research & prototyping including printing head, electronics, software algorithms which are the core of the system driving the electric field and the assembly process of nanoparticles implemented in XTPL’s Nanometric Lab Printer. It is a device that offers necessary functionalities to test, evaluate and use XTPL line-forming technology with nanometric precision and enables positioning of the printing head with micrometric resolution precisely.

Official video explaining XTPL’s technology: https://youtu.be/WMerzxzCXuw

Filmed at the I-Zone demo and prototype area at SID Display Week, the world’s largest and best exhibition for electronic information display technology.

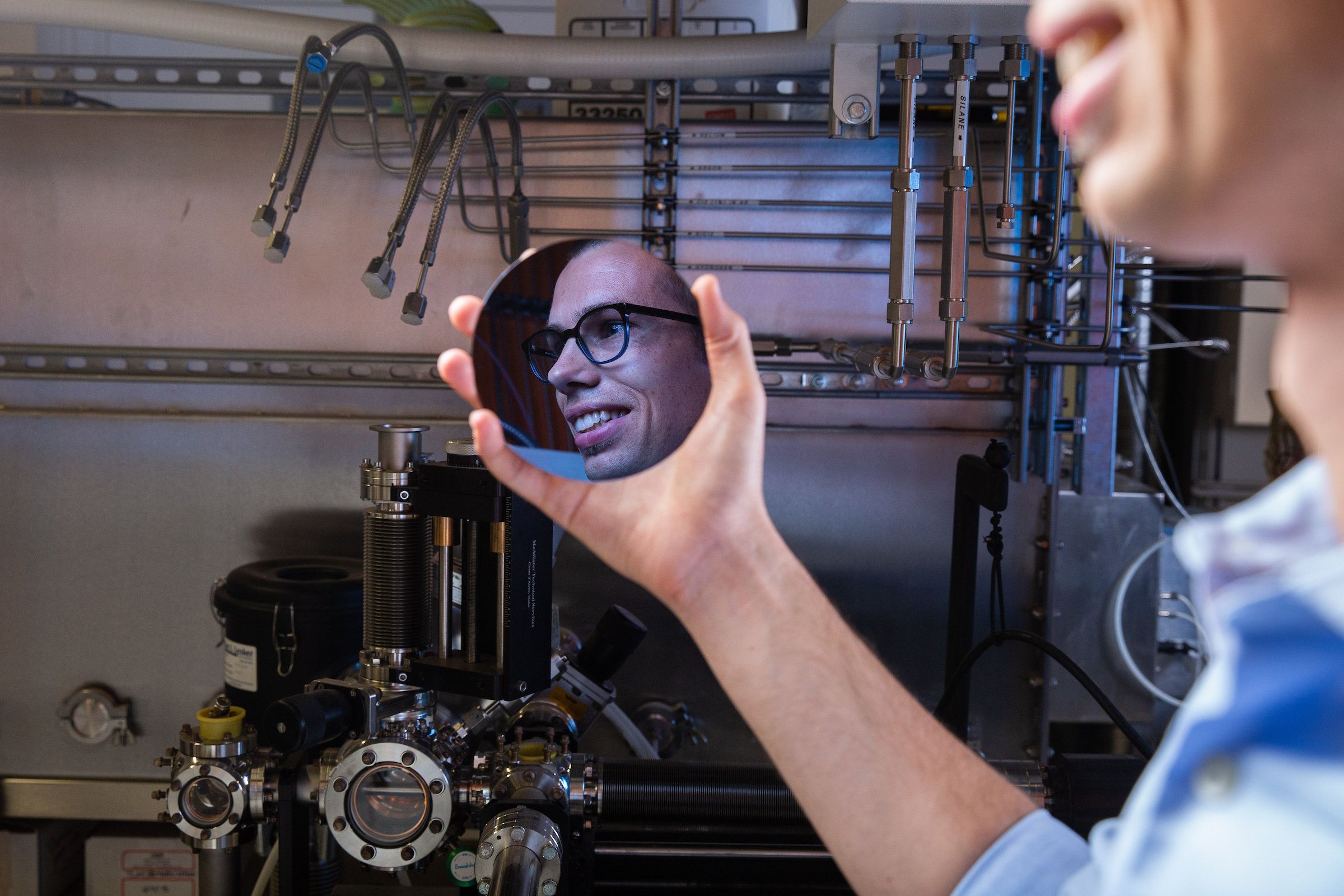

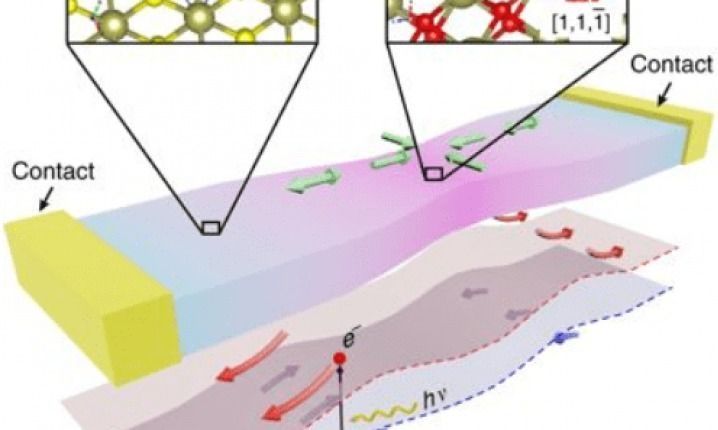

UK researchers can now ‘funnel’ electrical charge onto a chip. Using the atomically thin semiconductor hafnium disulphide (HfS2), which is oxidized with a high-intensity UV laser, the team were able to engineer an electric field that funnels electrical charges to a specific area of the chip, where they can be more easily extracted.

This method has the potential to harvest three times the energy compared with traditional systems. The researchers believe their breakthrough could result in solar panels, no bigger than a book, producing enough energy to power a family-sized house.

The financial costs of flooding in Canada’s maritime region could spike by 300 per cent by the end of the century if steps are not taken to address the impacts of climate change.

A study done by researchers at the University of Waterloo looked at the Halifax, Nova Scotia area, a region hard hit by recent riverine flooding. The team, made up economists, geographers and political scientists, merged data on flood probability, climate change and financial payout information from the insurance/re-insurance market and used the information to develop a forecast.

“Until recently there hasn’t been a lot of work exploring what increased flooding will cost, and who will get stuck with the bill,” says Andrea Minano, coordinator of the Canadian Coastal Resilience Forum (CCRF) and a researcher at Waterloo’s Faculty of Environment. “The increases in flood losses put into question the long term insurability in the Halifax area, and highlight a broader problem facing many other areas in Canada if no actions are taken to mitigate and adapt to climate change.”

A new study carried out by an international team of researchers, using the chemistry of ocean sediments has highlighted a widespread picture of Atlantic circulation changes associated with rapid climate change in the past.

The new integrated dataset, published today in the journal Nature Communications, provides new insights into the interactions of melting ice, ocean circulation and climate change, with potential implications for future long-term changes in the Earth systems with global climate change.

Dr. Hong Chin Ng from the University of Bristol’s School of Earth Sciences, is the study’s lead author.