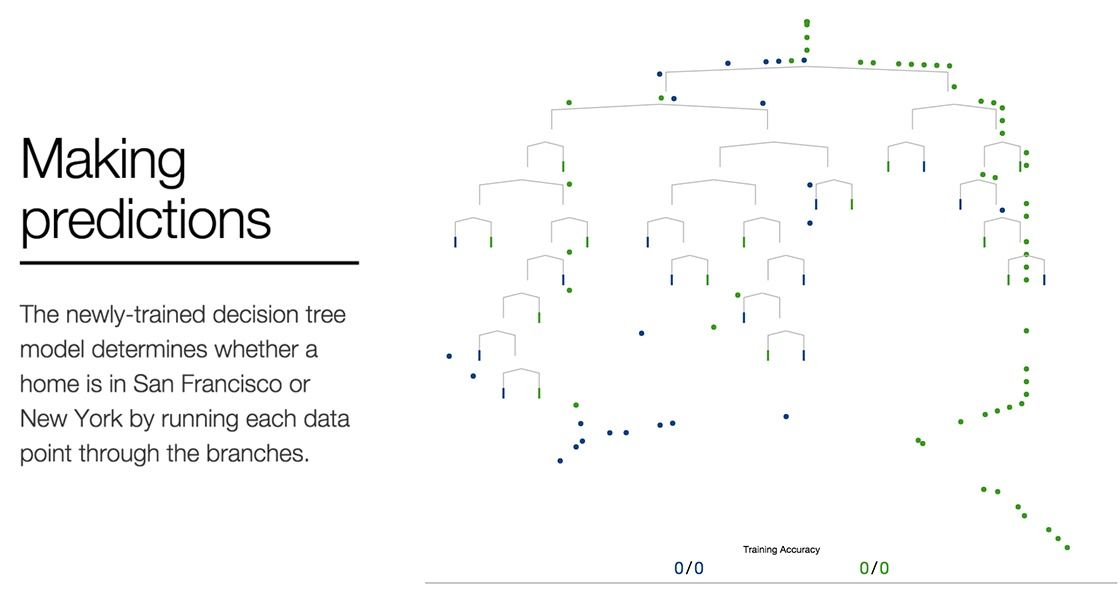

I like the concept; however, as long as “connected AI” is connected to the Net or any network infrastructure, or platform that is connected to a network and the network infrastructure/ net can be hacked; companies and consumers will still finding themselves closely monitoring the AI systems & machines which could cost companies more money and not less money. So, this does place a concern on the investments being made to develop technology that may not be fully adopted as it once was hoped.

Australians could be working alongside artificial devices and robotic devices within the next 20 years, according to a landmark report by the Federal Government’s agency for scientific research.

The CSIRO has launched a report claiming that rapid advances in automated systems and artificial intelligence meant that robotic devices would be able to perform many tasks more quickly, safely and efficiently than humans.

The report, commissioned by the Federal Government in partnership with the Australian Computer Society, Boston Consulting Group and ANZ, “mapped out the changing landscape of our workforce as we move through huge technological shifts”, according to Minister for Employment, Senator Michaelia Cash.