A team of researchers from Heriot-Watt University, the Indian Institute of Technology and the University of Glasgow has demonstrated a way to transport entangled particles through a commercial fiber cable with 84.4% fidelity. In their paper published in the journal Nature Physics, the group describes using a unique attribute of entanglement to achieve such high fidelity. Andrew Forbes and Isaac Nape with the University of Witwatersrand have published a News & Views piece in the same journal issue outlining issues with sending entangled particles across fiber cables and the work done by the team in this new effort.

The study of entanglement, its properties and possible uses has made headlines due to its novelty and possible applications —particularly in quantum computers. One of the roadblocks standing in the way of its use as an international computer communications medium is noise encountered along the path through fiber cables that destroys the information they carry. In this new effort, the researchers have found a possible solution to the problem—using a unique attribute of entanglement to reduce losses due to noise.

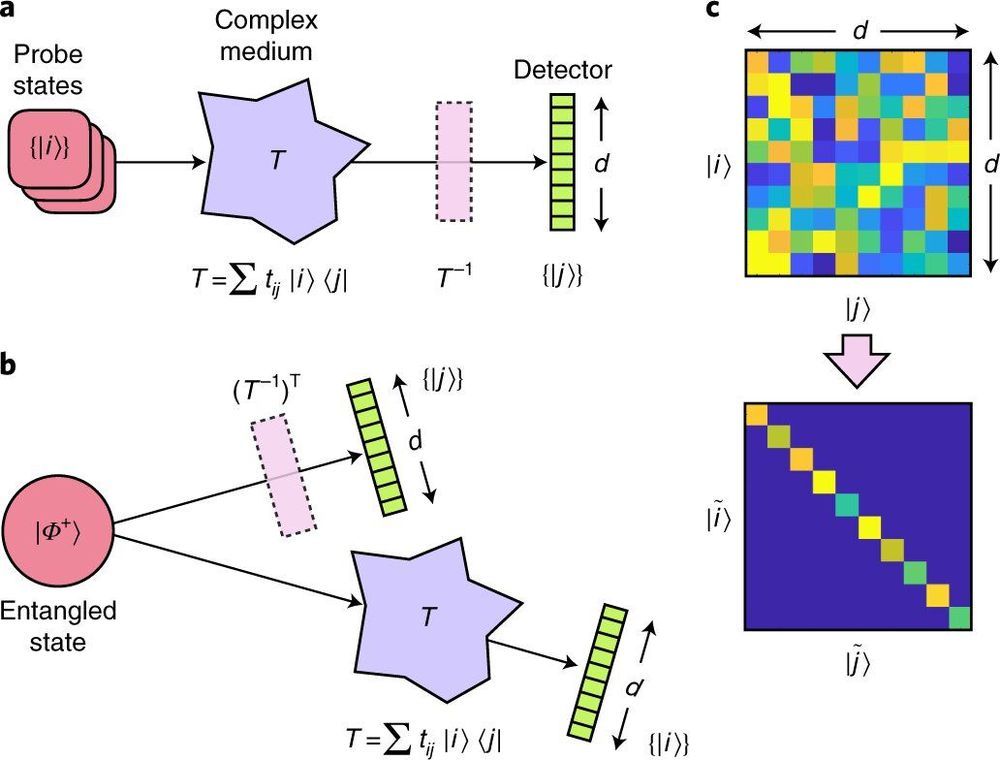

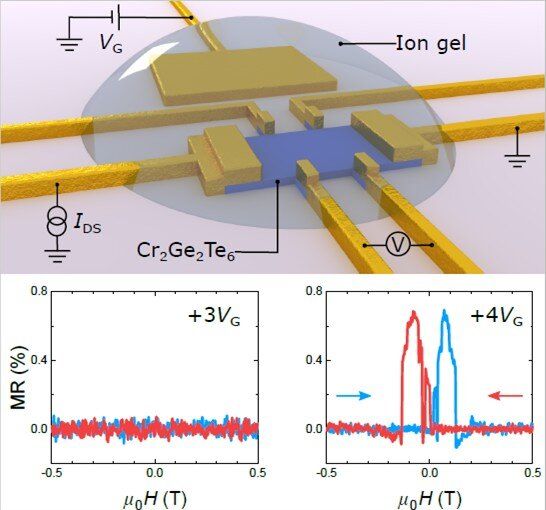

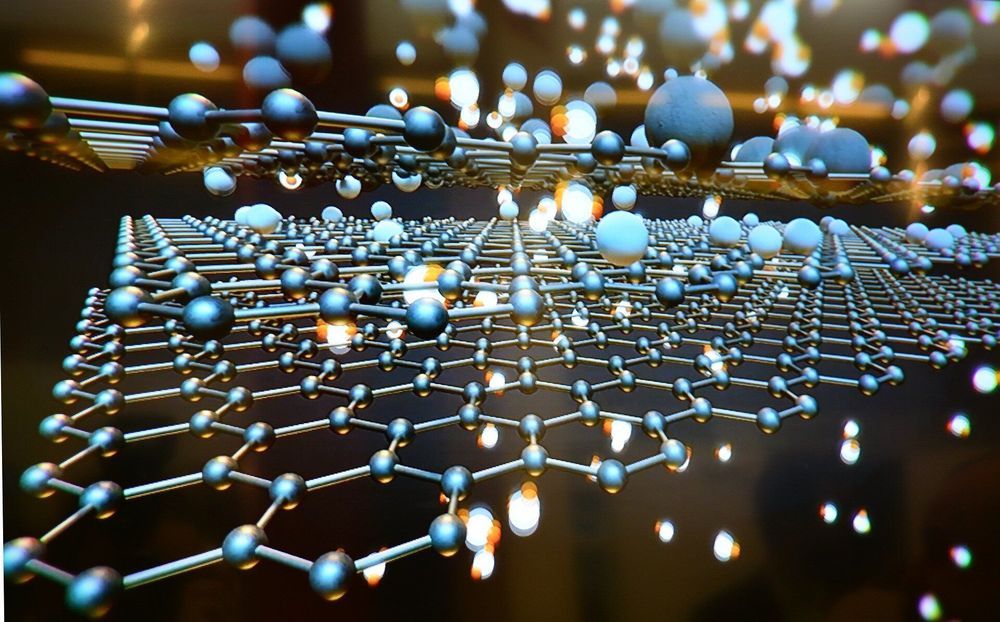

The work exploited a property of quantum physics that allows for mapping the medium (fiber cable) onto the quantum state of a particle moving through it. In essence, the entangled state of a particle (or photon in this context) created an image of the fiber cable, which allowed for reversing the scattering within it as a photon was transmitted. And furthermore, the descrambling could be achieved without having anything touch either the fiber or the photon that moved through it. More specifically, the researchers sent one of a pair of photons through a complex medium, but not the other. Both were then directed toward spatial light modulators and then on to detectors, and then finally to a device used to correlate coincidence counting. In their setup, light from the photon that did not pass through the complex medium propagated backward from the detector, allowing the photon to appear as if it had emerged from the crystal as the other photon.