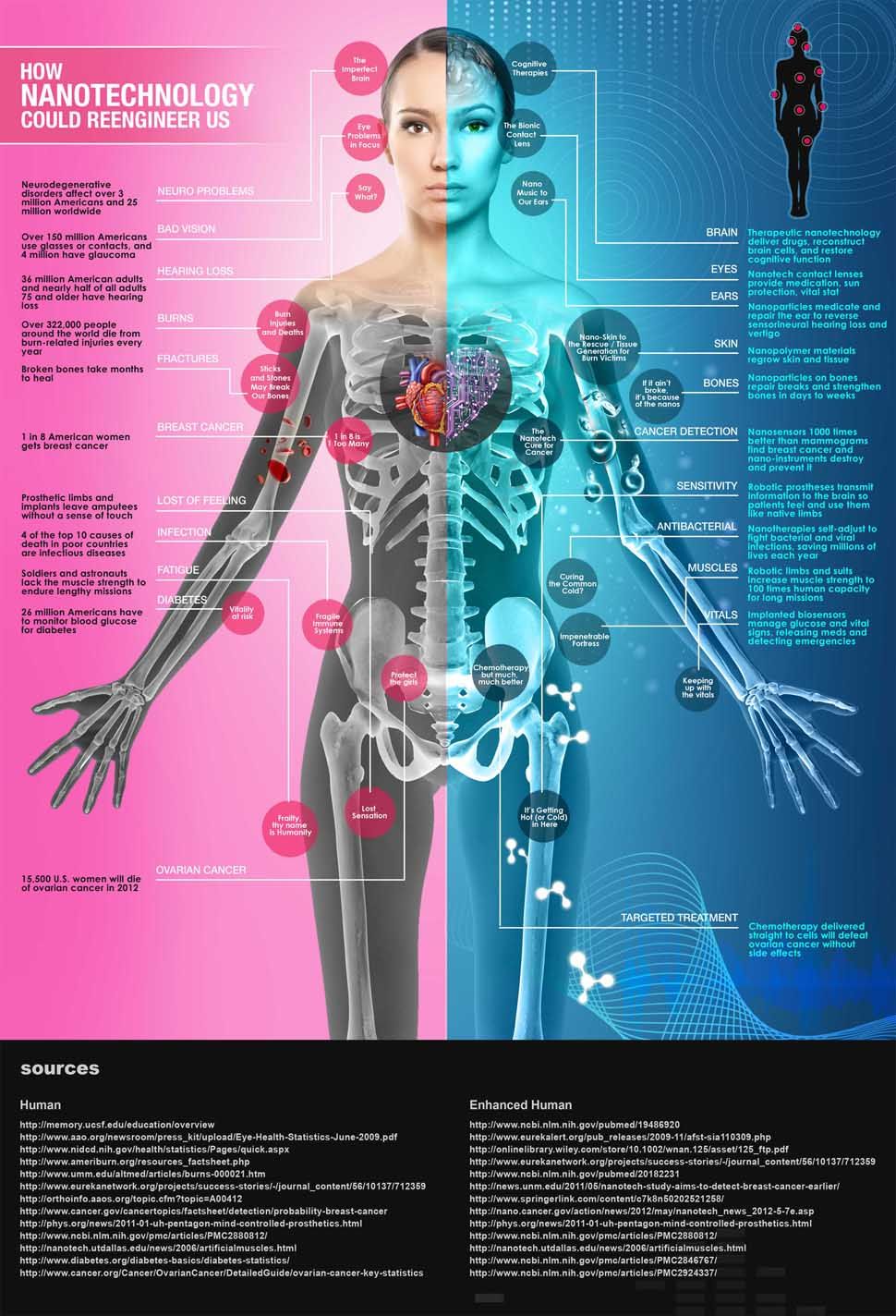

Researchers in Australia have developed a patch lined with microscopic needles that can quickly and painlessly detect disease-carrying proteins in the blood, potentially replacing the need for needle-based blood samples, and time spent waiting for lab analysis.

Based on a similar patch that could one day deliver injection-free vaccines through the skin, the diagnostic nanopatch has been designed to identify diseases such as malaria and dengue fever, which are prevalent in remote areas and developing regions where people might not have the resources to routinely draw blood and analyse it.

“The concept here is that we could just put a patch on the skin and this could give a result based on what it can find in your blood,” one of the researchers, Simon Corrie from the University of Queensland, told Fairfax Media. “The microneedle arrays can capture proteins that circulate around the body that are normally tested for in blood samples.”