Hundreds of comments under his post today: http://www.newsweek.com/quantum-archaeology-quest-3d-bioprint-every-dead-person-back-life-837967

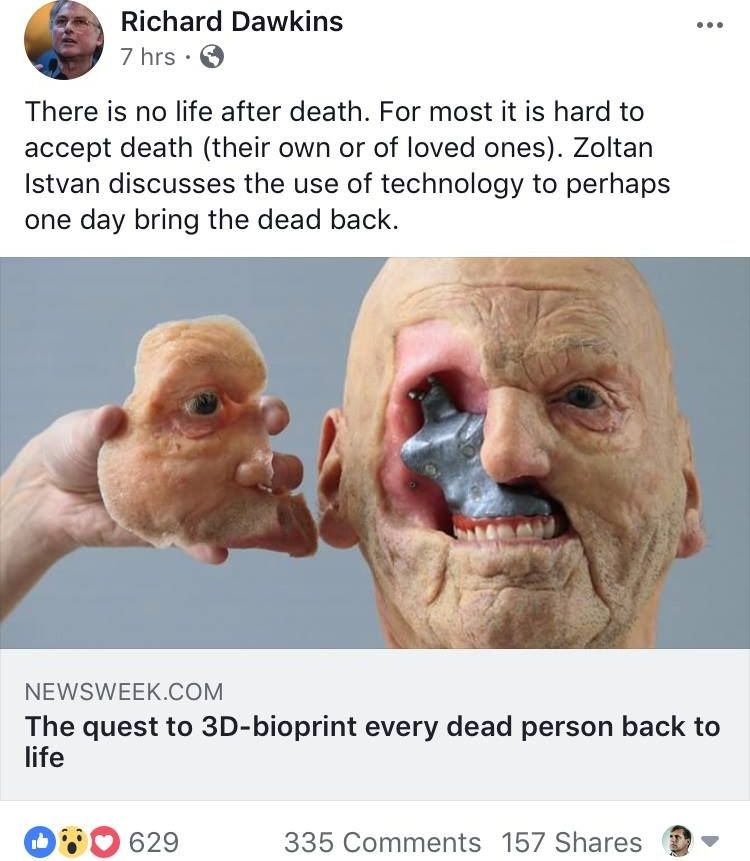

Summary: A startup wants to develop bioprinted beating hearts using stem cells from a patient’s own body using a special 3D bioprinter. [This article first appeared on LongevityFacts. Author: Brady Hartman. ]

A startup called BioLife4D wants to develop bioprinted beating hearts using a patient’s own cells as solution for patients seeking heart transplants.

As first reported on USAToday, Steven Morris, the CEO founding partner and of BioLife4D says that if the bioprinted heart is successful, the company hopes to expand to other organs including the pancreas or the kidneys.

Trinity College Dublin (TCD), in Ireland, is to be the recipient of a new specialist 3D bioprinting facility supported by a collaboration between multinational medical device and pharmaceutical company Johnson & Johnson, and the AMBER research center.

With preparations beginning in the first quarter of this year, the new 3D bioprinting laboratory is due to be opened by the close of 2018.

Professor Michael Morris, AMBER director, comments.

https://youtube.com/watch?v=-5jcq3RlxJQ

Cell by Cell

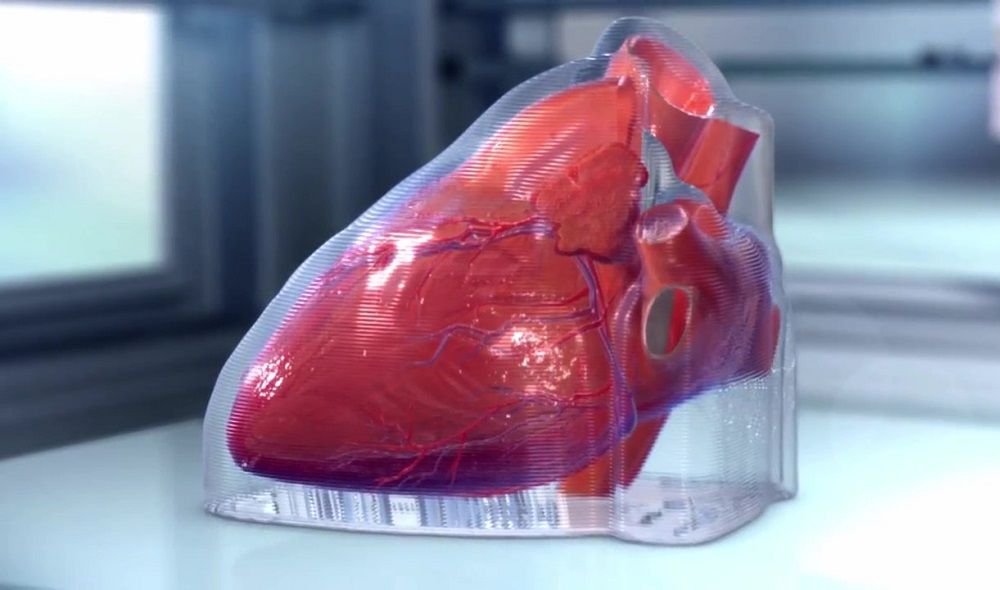

3D-printing technology has made significant strides over the past several years. What started as a tool for producing small objects can now be used to craft food, build houses, and even construct “space fabric.”

One of the tech’s most impressive applications, however, is the creation of artificial tissues and organs, a process known as 3D bioprinting, and now, a team of researchers from the University of Oxford has developed a new method that takes 3D bioprinting to the next level. They published their work in the journal Nature Communications.

Bioprinting new organs and tissues could make transplants available and affordable for all, but is still decades away. In the meantime, scientists have re-purposed the technology to 3D print biocompatible high-precision silicone implants instead.

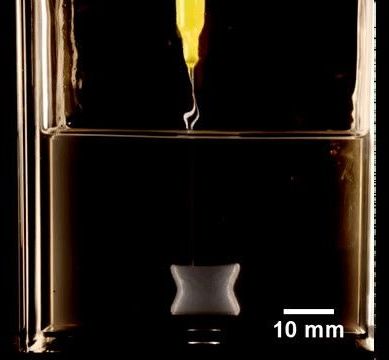

Soft materials like biological material or silicone are difficult to 3D print because they can’t support themselves like the more rigid plastics typically used by 3D printers. In 2015, Tommy Angelini’s lab at the University of Florida developed a new way of 3D printing soft materials by injecting them into a granular gel similar to hand sanitizer that supports them as they are deposited.

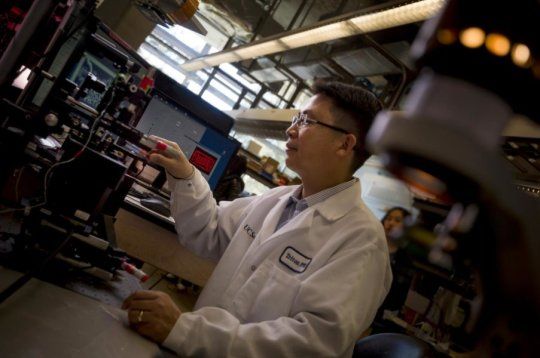

Every day in a San Diego lab, raw material derived from donated tissue unsuitable for organ transplantation goes into a machine, and three-dimensional human liver tissue is printed out.

Pioneered by a company called Organovo, this 3D bioprinting technology may one day achieve the Holy Grail of its industry: the manufacturing of whole human organs to replace damaged ones. But for now, it’s already making an impact on human health, as pharmaceutical and biotech companies are using its manufactured human liver tissue to test the toxicity of new drugs and therapies.

Organovo is developing multiple tissue types for therapeutic use, with strong early results in animal models. In three to five years, there’s a good chance that it will have an Investigational New Drug Application in at least one tissue. The company’s strategic plan is coming to fruition just as its chief scientific officer, Sharon Presnell, envisioned when she joined the startup in 2011.

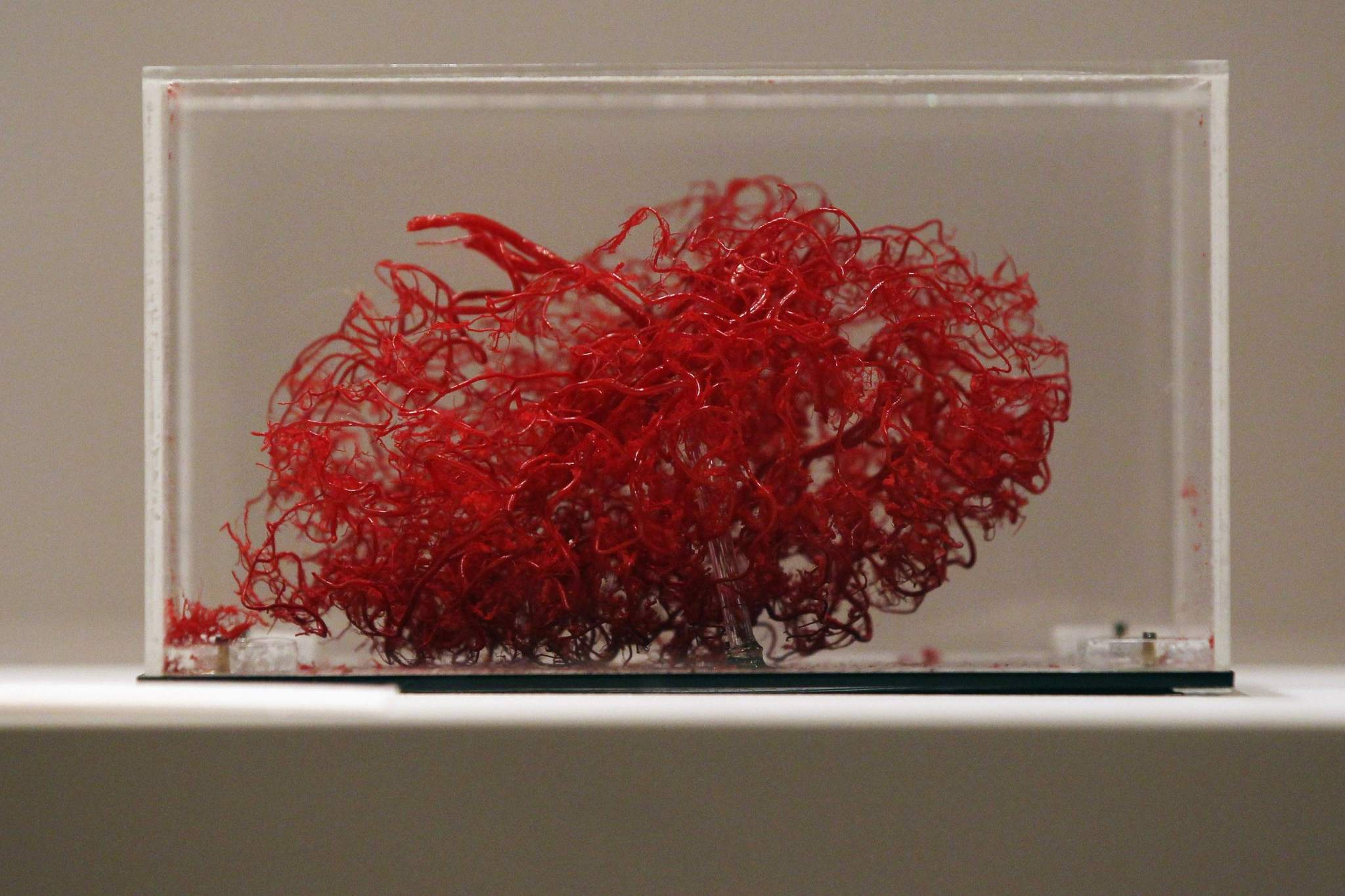

The new research, led by nanoengineering professor Shaochen Chen, addresses one of the biggest challenges in tissue engineering: creating lifelike tissues and organs with functioning vasculature — networks of blood vessels that can transport blood, nutrients, waste and other biological materials — and do so safely when implanted inside the body.

Researchers from other labs have used different 3D printing technologies to create artificial blood vessels. But existing technologies are slow, costly and mainly produce simple structures, such as a single blood vessel — a tube, basically. These blood vessels also are not capable of integrating with the body’s own vascular system.

“Almost all tissues and organs need blood vessels to survive and work properly. This is a big bottleneck in making organ transplants, which are in high demand but in short supply,” said Chen, who leads the Nanobiomaterials, Bioprinting, and Tissue Engineering Lab at UC San Diego. “3D bioprinting organs can help bridge this gap, and our lab has taken a big step toward that goal.”

Researchers from the University of California, San Diego have successfully 3D printed a framework of functional blood vessels. Blood vessel networks are important in transporting blood, nutrients and waste around the human body.

The research team employed a 3D bioprinting process involving hydrogel and endothelial cells. Endothelial are the form of cells that make up the inner lining of blood vessels.

Leading the research was Shaochen Chen, who explains the motivation of the project.