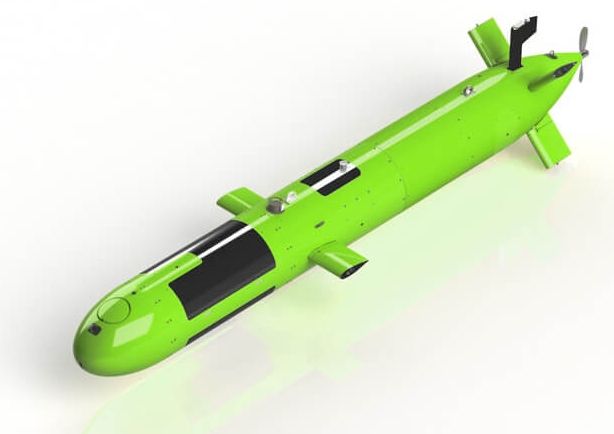

3D printed bridge in Spain. Could this some day be our answer to reducing costs around US state and county infrastructure costs related to bridges and other structural repairs related to infrastructure?

The pedestrian crossing 3D-printed bridge installed in the urban park of Castilla La Mancha in Madrid, Spain, back in December is now ready to be used.

The 39-foot-long bridge was printed in micro-reinforced concrete at the Institute for Advanced Architecture of Catalonia.

In addition to the 3D printing, the production process was also environmentally friendly allowing the team to optimize the distribution of materials, minimize the amount of water, and recycle the raw material during manufacture.