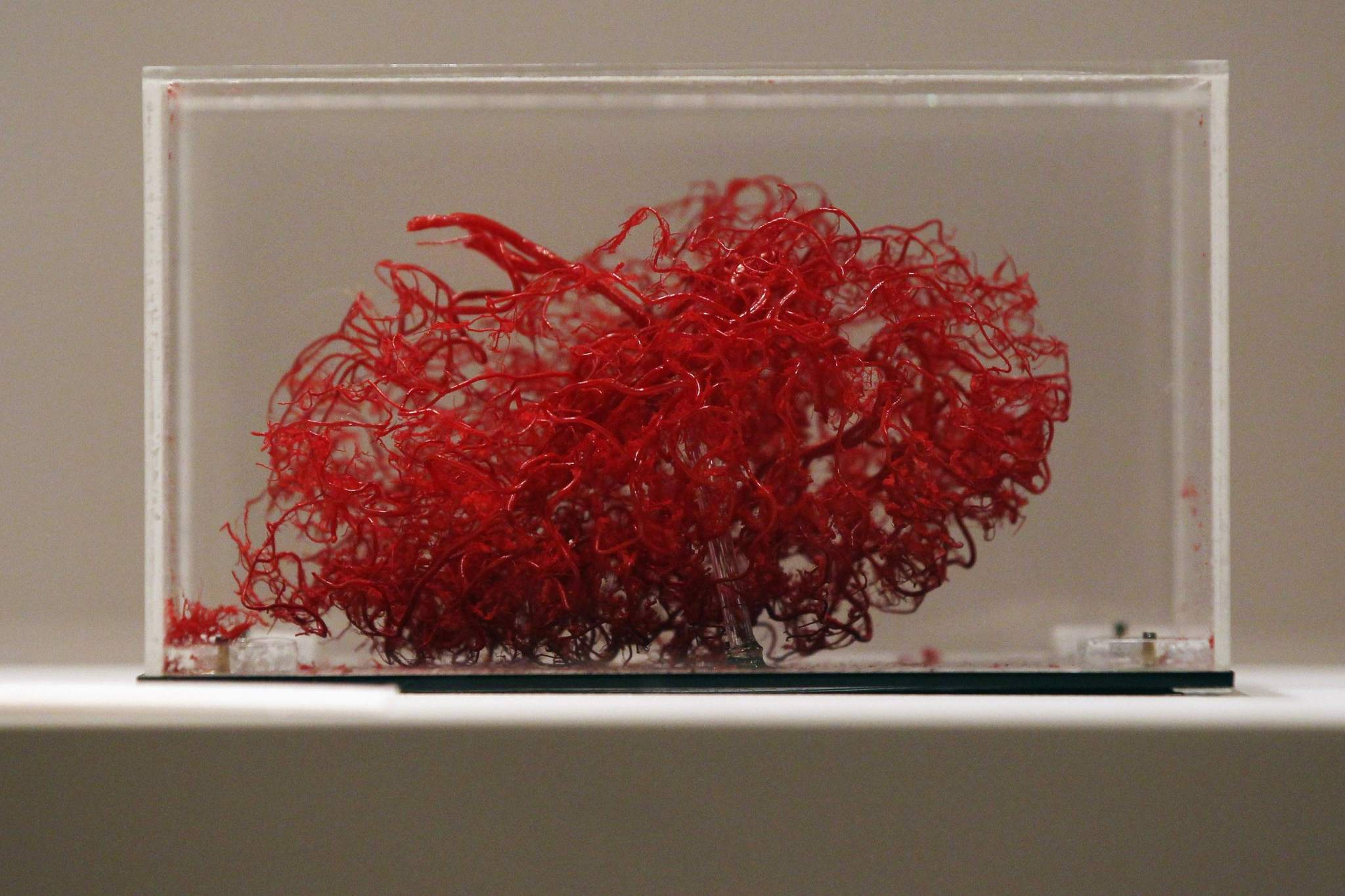

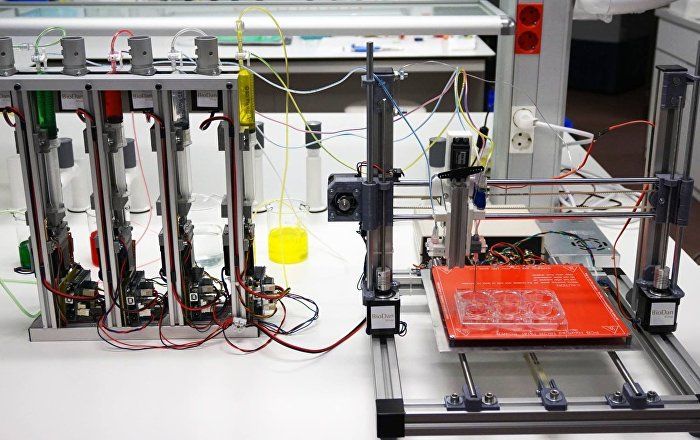

Researchers at ETH Zurich and IBM Research Zurich have built a tiny redox flow battery. This means that future computer chip stacks — in which individual chips are stacked like pancakes to save space and energy — could be supplied with electrical power and cooled at the same time by such integrated flow batteries (Energy & Environmental Science, “3D-printed fluidic networks for high-power-density heat-managing miniaturized redox flow batteries”).

In a flow battery, an electrochemical reaction is used to produce electricity out of two liquid electrolytes, which are pumped to the battery cell from outside via a closed electrolyte loop.