This could lead to a small 3D printer used by soldiers to quickly make anything needed in the field.

Manufacturing is dirty, dull, and outmoded. It’s a slow-moving industry stuck in the past as new technologies out of Silicon Valley threaten to upend it. Stereotypes are fun, and misleading.

Let’s not forget manufacturing is the industry that made the modern age.

While many were musing about robots in science fiction, manufacturers were putting them to practical use. As tech news headlines hyped up 3D printing, manufacturers had been prototyping with it for decades. And though information technology is the source of the latest revolution, manufacturing is the source of the source. No chip fab facilities, no chips.

Equipped with 3D printers, CNC machines, computers, digital tools and other equipment, a fabrication laboratory, otherwise known as a Fab Lab, is a facility set up to enable people to ‘make anything’. In a bid to provide these capabilities to missions for deep-space exploration, NASA are accepting FabLab proposals from corporate, institutional and charitable teams in the private-sector, due to be reviewed late 2017.

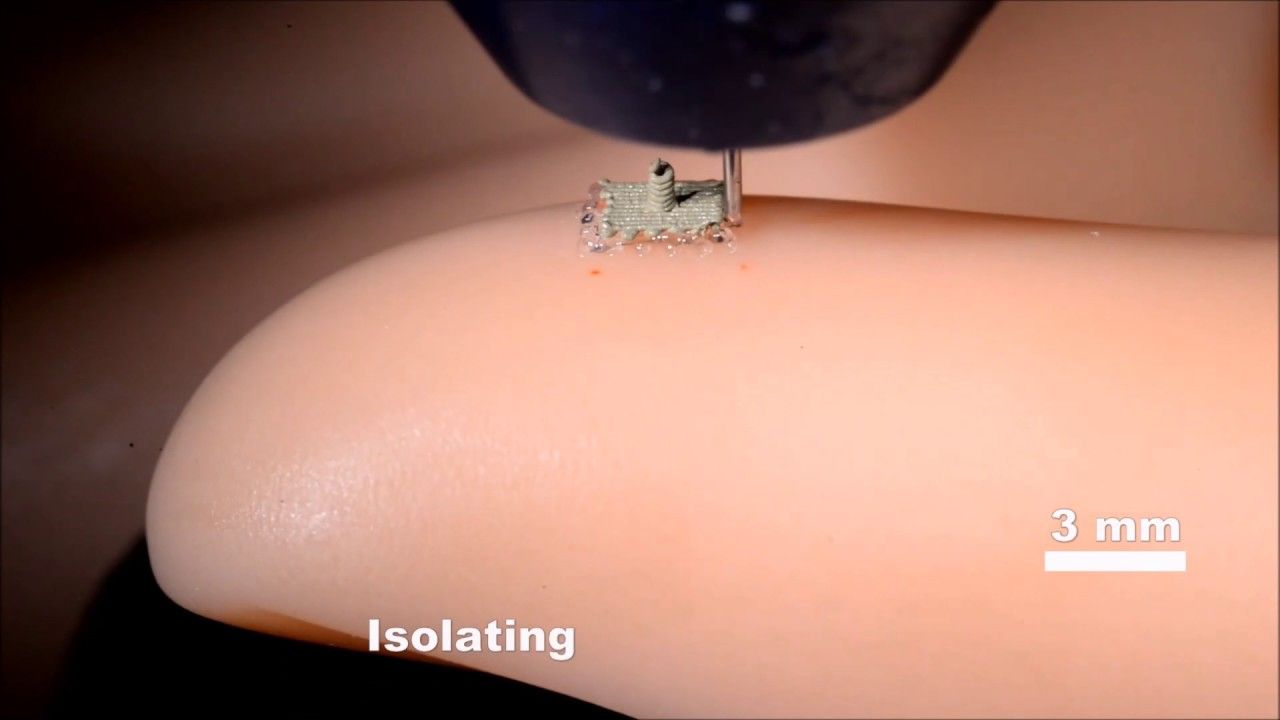

Bioprinting new organs and tissues could make transplants available and affordable for all, but is still decades away. In the meantime, scientists have re-purposed the technology to 3D print biocompatible high-precision silicone implants instead.

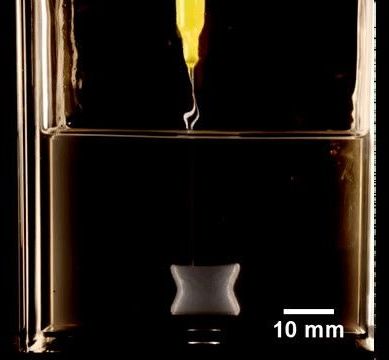

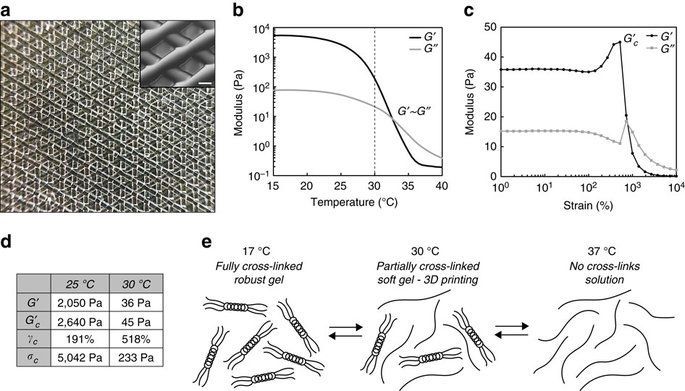

Soft materials like biological material or silicone are difficult to 3D print because they can’t support themselves like the more rigid plastics typically used by 3D printers. In 2015, Tommy Angelini’s lab at the University of Florida developed a new way of 3D printing soft materials by injecting them into a granular gel similar to hand sanitizer that supports them as they are deposited.

3D printed ovaries restore fertility to mice. Another step towards more complex organs.

There is a clinical need to develop a bioengineering system to support ovary transplantation. Here, the authors generate a bioprosthetic ovary using 3D printed scaffolds of varying pore architectures to support follicle survival and ovarian function in sterilized mice.

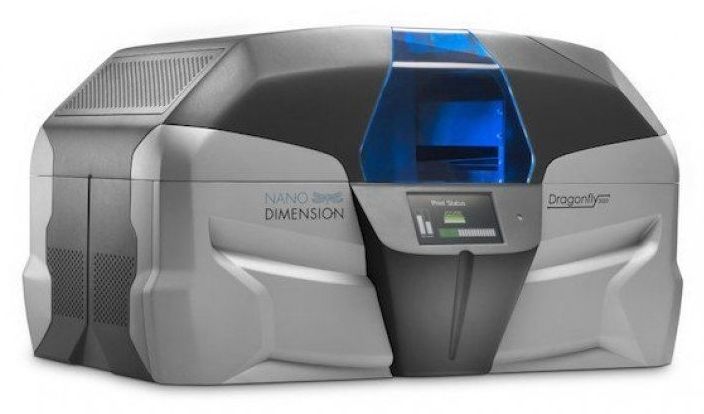

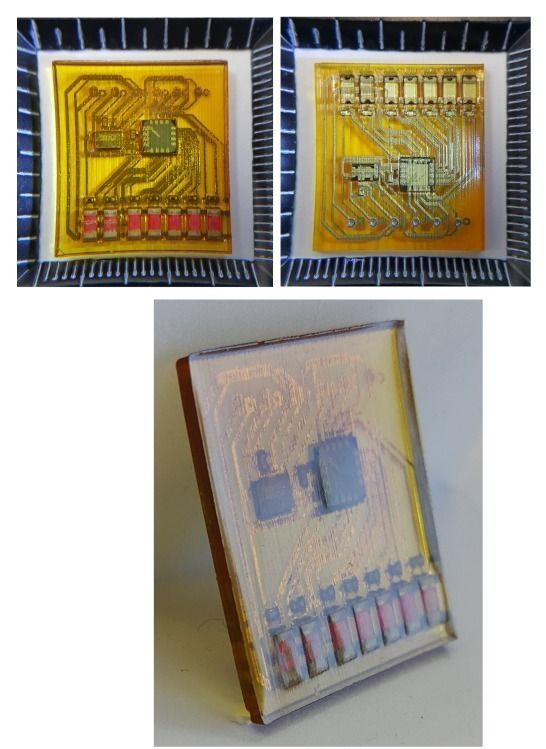

Nano Dimension (NASDAQ, TASE: NNDM) is focused on the research and development of advanced 3D printed electronics, including a 3D printer for multilayer printed circuit boards, and the development of nanotechnology-based conductive and dielectric inks, which are complementary products for 3D printers.

Nextbigfuture interviewed Amit Dror, CEO and cofounder of Nano Dimension. Amit is a project leader with extensive experience in company and account management.

Nano Dimension’s novel and proprietary technologies enable the use of conductive and dielectric inks for ultra-rapid prototyping of complex, high-performance multilayer circuit boards. The company’s PCB 3D printer is the result of combining advanced breakthroughs in inkjet technology, 3D printing and nanotechnology.

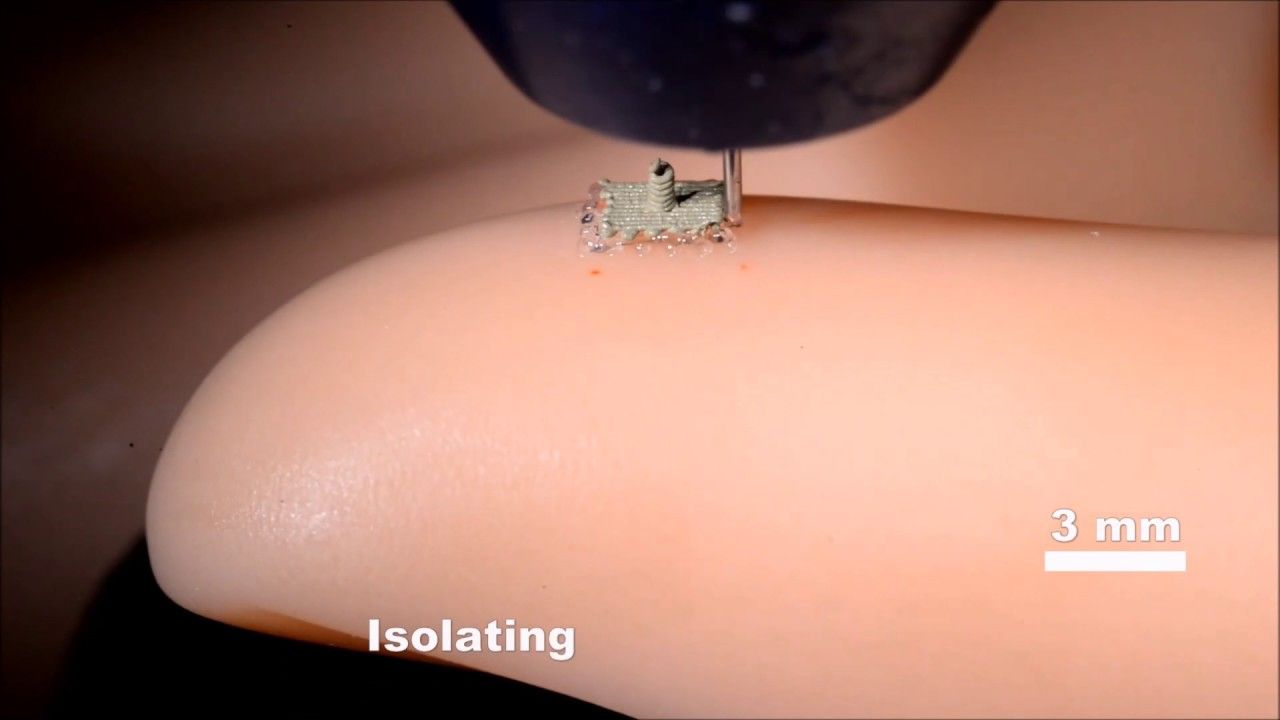

Simon Fried, Nano Dimension CBO, describes the next five years of industrial 3D printing. It will be meeting more needs. In mechanical terms, that means 3D printing will use a broader range of materials or a higher quality of materials.

We also expect greater flexibility in combining materials – creating objects made of different types of metals, for instance, within the same print. Or printing metals and polymers, or metals and ceramics in one print job. With that capability, for instance, companies can begin deploying addition functionality within parts, such as electrical capabilities to mechanical objects. That’s the case with Nano Dimension, where polymers and metals are printed together with a very specific functional goal. Down the road, this capability will bring about stronger, smarter and more functional final products.