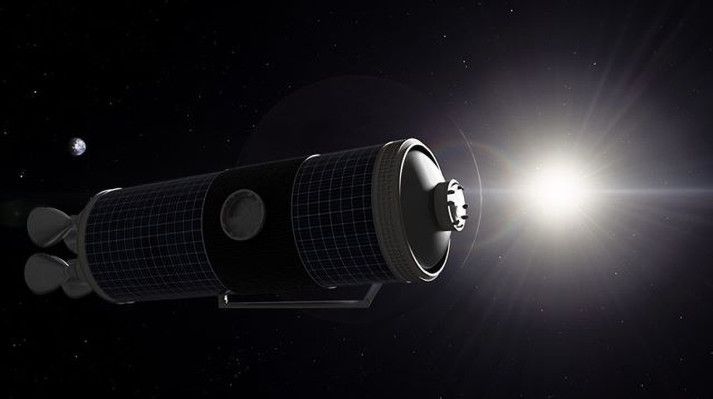

Looking forward to the first manned Mars mission, ESA is delving into how astronaut hibernation would affect space missions. Based on sending six humans on a five-year mission to the Red Planet, the study suggests that using hibernation would allow the mass of the spacecraft to be reduced by a third, and the amount of consumables cut by roughly the same amount.

The idea of astronauts sleeping their way through a deep-space mission lasting months or years has been a staple plot device of science fiction since at least the 1930s and has featured in many movies as a way to speed up the story. Despite the chance of waking up to find one’s self on a planet run by apes, it’s an idea that is very attractive to real-life mission planners as a way to both reduce the supplies needed for lengthy missions and to keep the crew from going crazy.

The technology to actually make humans hibernate like bears or other mammals is still in its infancy, but that hasn’t stopped ESA from looking at how hibernation could impact spacecraft designs and missions in general. Originally, studied as part of the space agency’s Basic Activities research, hibernation is regarded as a key enabling technology and now ESA’s Concurrent Design Facility (CDF), along with scientists from the Ludwig Maximilian University of Munich and the University of Goethe, Frankfurt, are looking at the advantages that sleeping astronauts might bring to a Mars mission.