This robot sees and analyzes trash the same way a person does, but sorts it a lot faster 🤖.

This robot sees and analyzes trash the same way a person does, but sorts it a lot faster 🤖.

It’s a problem that plagues even the priciest of lenses, manufactured to the most exacting specifications: the center of the frame might be razor-sharp, but the corners and edges always look a little soft. It’s a problem that’s existed for thousands of years with optical devices, and one that was assumed to be unsolvable until a Mexican physicist developed a mind-melting formula that could revolutionize how lenses are manufactured.

On paper, a curved glass lens should be able to redirect all the rays of light passing through it onto a single target known as its focal point. But in the real world, it just doesn’t work that way. Differences in refraction across the lens, as well as imperfections in its shape and materials, all contribute to some of those light rays, especially those entering the lens near its outer edges, missing the target. It’s a phenomenon known as spherical aberration, and it’s a problem that even Isaac Newton and Greek mathematician Diocles couldn’t crack.

Some call it a SASER and others call it a PHASER.

How do you whisper to someone across the room? With lasers, of course. MIT has developed a system using lasers to transmit audio signals directly to the ear, and no one else in the area can hear them. As a nice bonus, the laser won’t burn your skin or eyes should you turn your head at the wrong moment.

The laser system leverages what is known as the photoacoustic effect. That simply means that the absorption of light waves by a material produces sound waves. In this case, the light is absorbed by water molecules in the air, but the researchers learned to very carefully tune the laser to control where the sound appears. It’s essentially a narrow cone of sound.

Making sound with a laser is one thing, but creating specific tones or transmitting a message is much harder. The team evaluated two methods for doing this. First, there’s the laser sweeping technique, which involves altering the wavelength of light to create different sounds. The traditional photoacoustic method uses varying power to encode a message.

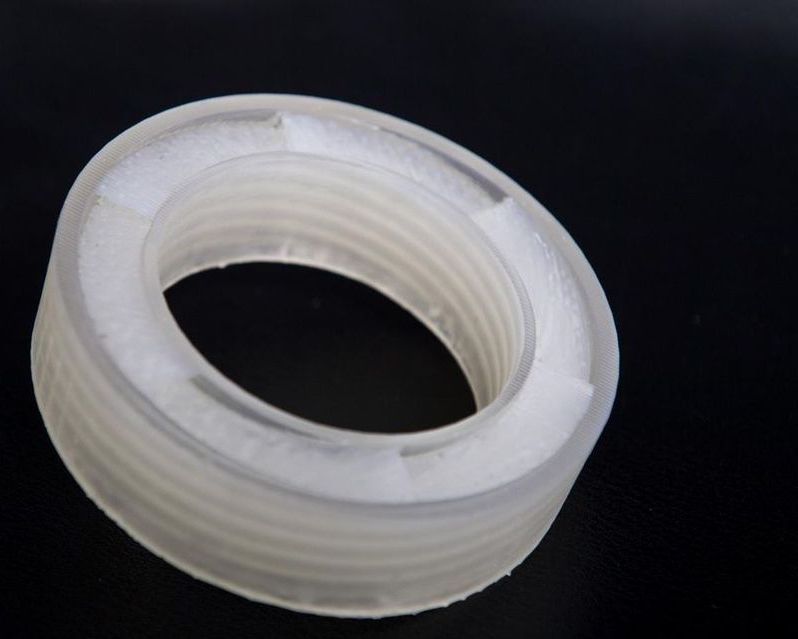

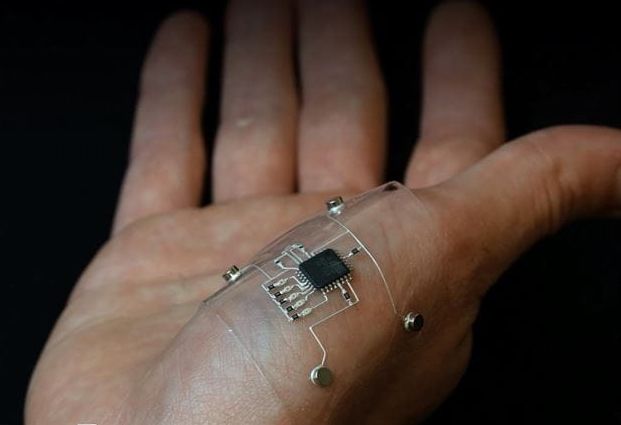

A technique called Hybrid 3D Printing, developed by AFRL researchers in collaboration with the Wyss Institute at Harvard University, uses additive manufacturing to integrate soft, conductive inks with material substrates to create stretchable electronic devices. A potential application is to create sensors to enable better human performance monitoring. (Courtesy photo/Harvard Wyss Institute)

https://www.wpafb.af.mil/…/afrl-harvard-researchers-invent…/

¬

NASA selects key commercial partnerships to further its new Moon to Mars strategy.

Today, NASA announced it has selected 12 U.S. commercial companies for 19 partnerships in its crewed Moon to Mars efforts, which kicks off with a planned 2024 Artemis program crewed return to the lunar surface.

The selections entail six key areas for future development as well as a category for other exploration technologies. They are: advanced communications, navigation and avionics; entry, descent and landing; in-space manufacturing and assembly; advanced materials; power; and propulsion.

“We’ve identified technology areas NASA needs for future missions, and these public-private partnerships will accelerate their development so we can implement them faster,” Jim Reuter, associate administrator of NASA’s space technology mission directorate, said in a statement.

Scientists at the University of Illinois have discovered a new way to make water, and without the pop. Not only can they make water from unlikely starting materials, such as alcohols, their work could also lead to better catalysts and less expensive fuel cells.

“We found that unconventional metal hydrides can be used for a chemical process called oxygen reduction, which is an essential part of the process of making water,” said Zachariah Heiden, a doctoral student and lead author of a paper accepted for publication in the Journal of the American Chemical Society, and posted on its Web site.

A water molecule (formally known as dihydrogen monoxide) is composed of two hydrogen atoms and one oxygen atom. But you can’t simply take two hydrogen atoms and stick them onto an oxygen atom. The actual reaction to make water is a bit more complicated: 2H2 + O2 = 2H2O + Energy.

We need these biodegradable “plastic” bags everywhere.

Check us out on Instagram: https://attn.link/2LdWfTp

Rather than waiting around for serendipity, materials scientists would like to dream up a wonder material and then figure out how to make it. It’s this “inverse” approach to designing materials—working backward from the desired properties—that the team is calling “digital alchemy.”

“It really allows us to focus on the outcome and leverage what we know to find a starting point to building that material,” says Greg van Anders, a corresponding author of the paper and now an assistant professor of physics at Queen’s University in Kingston, Ontario.