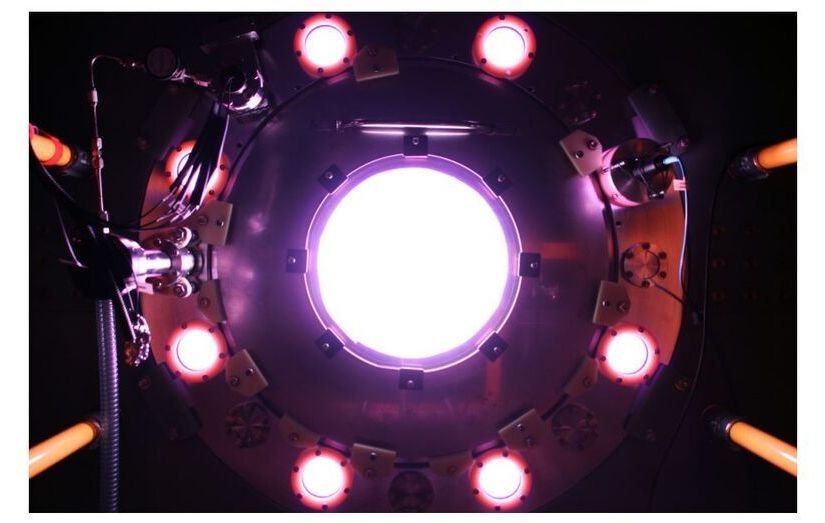

REDMOND, Wash.—(BUSINESS WIRE)—Helion Energy (Helion), a clean electricity company committed to creating a new era of clean energy through fusion, today became the first private company to announce exceeding 100 million degrees Celsius in their 6th fusion generator prototype, Trenta. Reaching this temperature is a critical engineering milestone as it is considered the ideal fuel temperature at which a commercial power plant would need to operate. Helion will be presenting these operational results at the 63rd Annual Meeting of the APS Division of Plasma Physics. See abstract below.

“These achievements represent breakthroughs with major implications for how the world meets its expanding future electricity needs while dramatically reducing climate impact on a relevant timescale” Tweet this

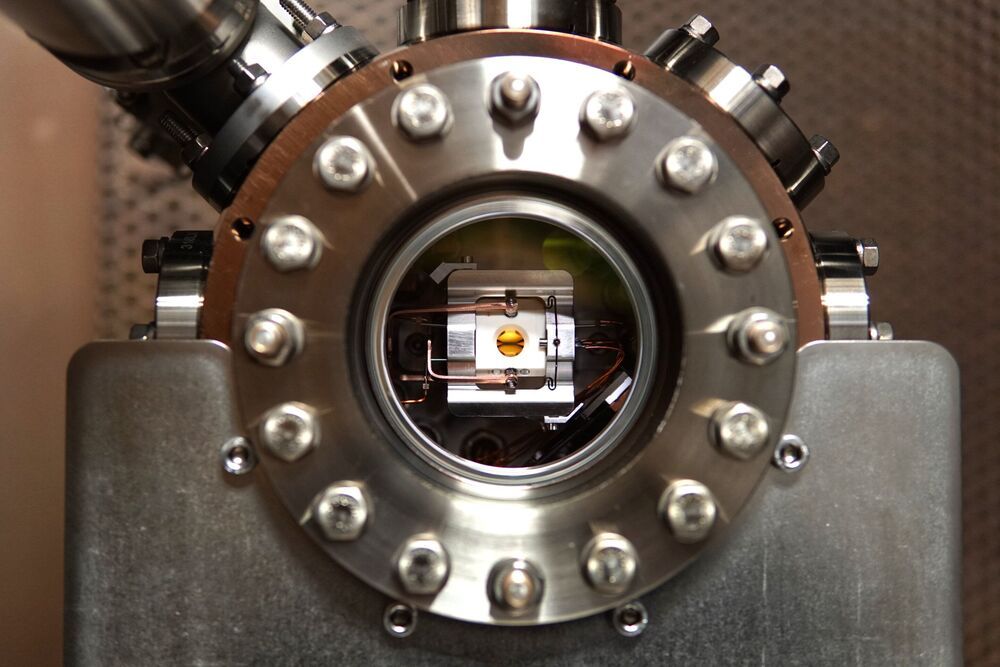

Helion also announced their Trenta prototype recently completed a 16-month testing campaign, which pushed fusion fuel performance to unprecedented levels and performed lifetime and reliability testing on key components of the fusion system. Helion will be presenting these results at the 2021 IEEE Pulsed Power Conference & Symposium on Fusion Engineering. See abstract below.