If you’ve ever held a high-quality camera lens, the first thing you notice is the weight. Thanks to layers and layers of thick glass hunks inside, they end up being very heavy. However, thanks to research being done at Harvard on something called metalenses, one day those mgiant glass-filled lenses might be obsolete.

The curved surfaces on a glass lens focus incoming light onto a camera’s digital sensor. The more precise (and expensive) the lens is, the better the image it will produce.

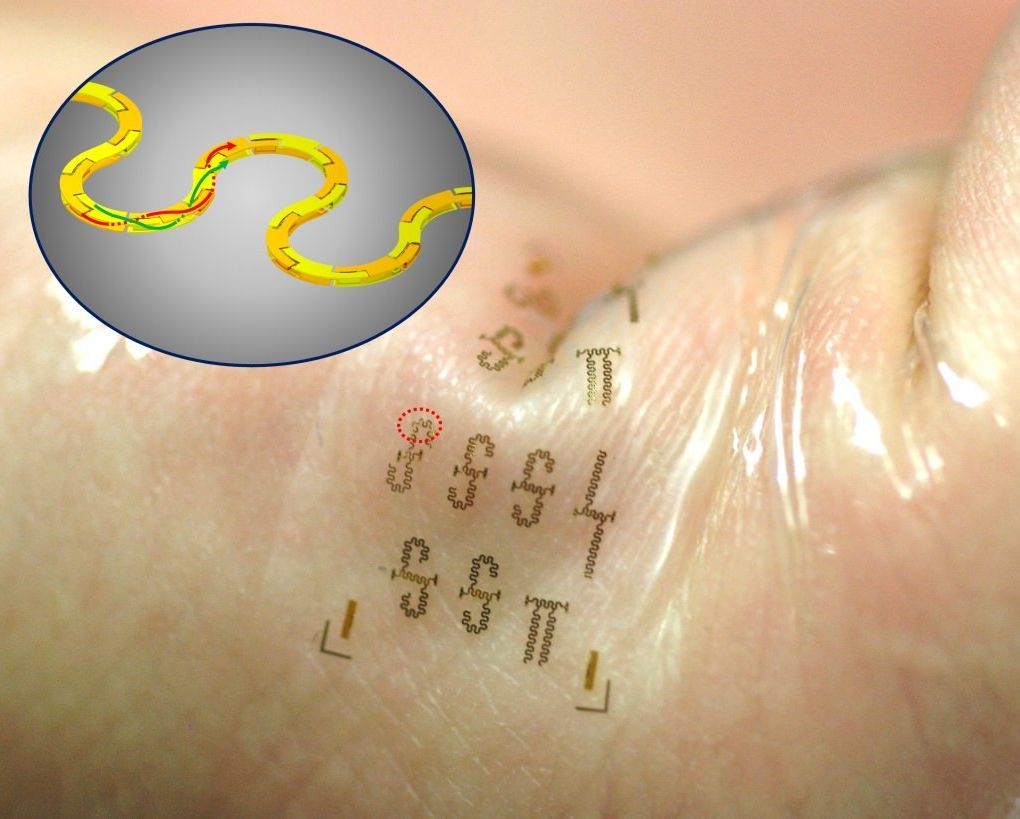

Metalenses work in a similar way, but they’re not made of precision-ground glass. Instead, a layer of transparent quartz is completely covered in a layer of tiny towers made from titanium dioxide. When arranged in specific patterns, those complex tower arrays can focus light exactly like a glass lens does. Except that these tiny metalenses end up being thinner than a human hair, and weigh almost nothing.