A family of compounds known as perovskites, which can be made into thin films with many promising electronic and optical properties, has been a hot research topic in recent years. But although these materials could potentially be highly useful in applications such as solar cells, some limitations still hamper their efficiency and consistency.

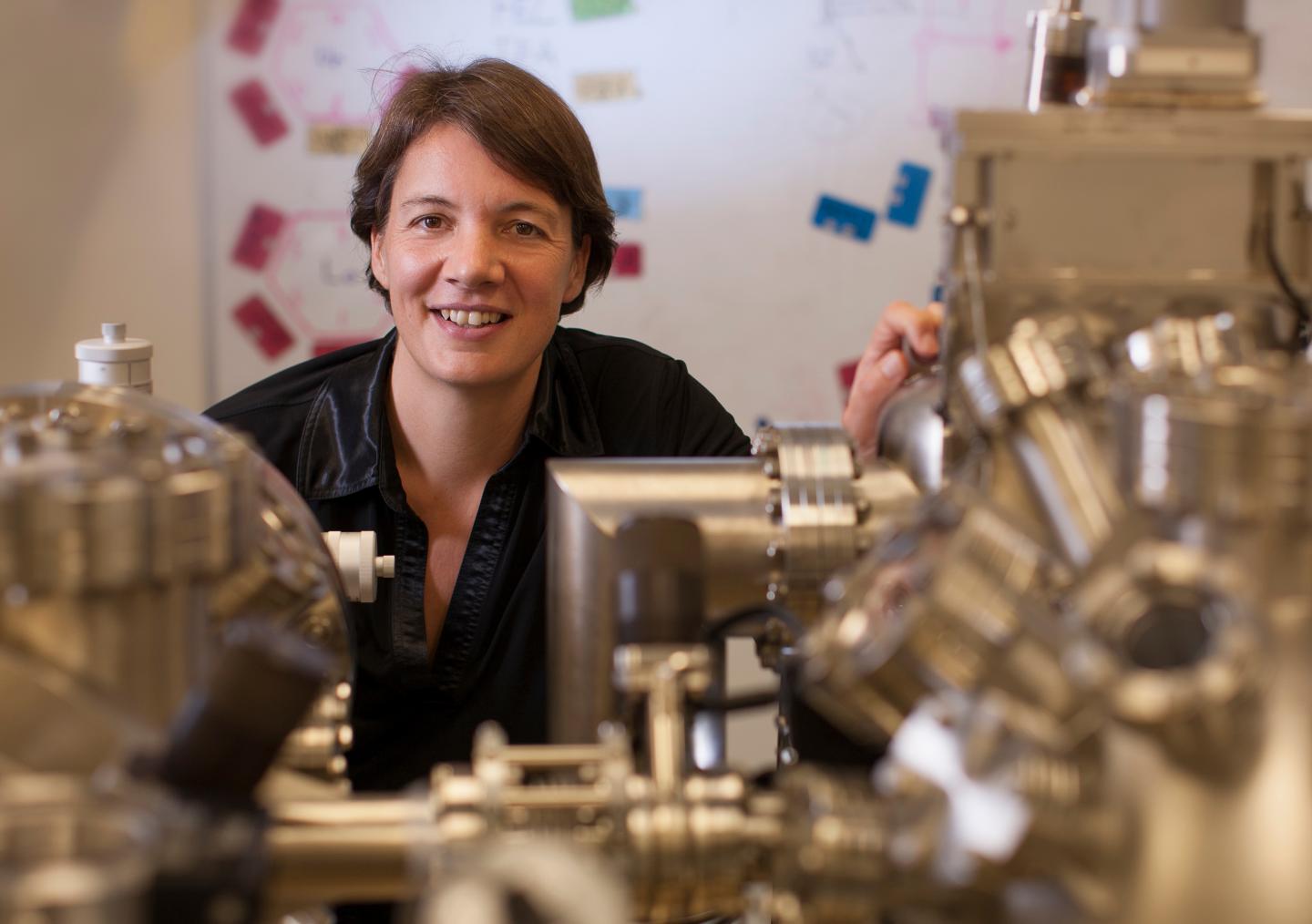

Now, a team of researchers at MIT and elsewhere say they have made significant inroads toward understanding a process for improving perovskites’ performance, by modifying the material using intense light. The new findings are being reported in the journal Nature Communications, in a paper by Samuel Stranks, a researcher at MIT; Vladimir Bulovic, the Fariborz Maseeh (1990) Professor of Emerging Technology and associate dean for innovation; and eight colleagues at other institutions in the U.S. and the U.K. The work is part of a major research effort on perovskite materials being led by Stranks, within MIT’s Organic and Nanostructured Electronics Laboratory.

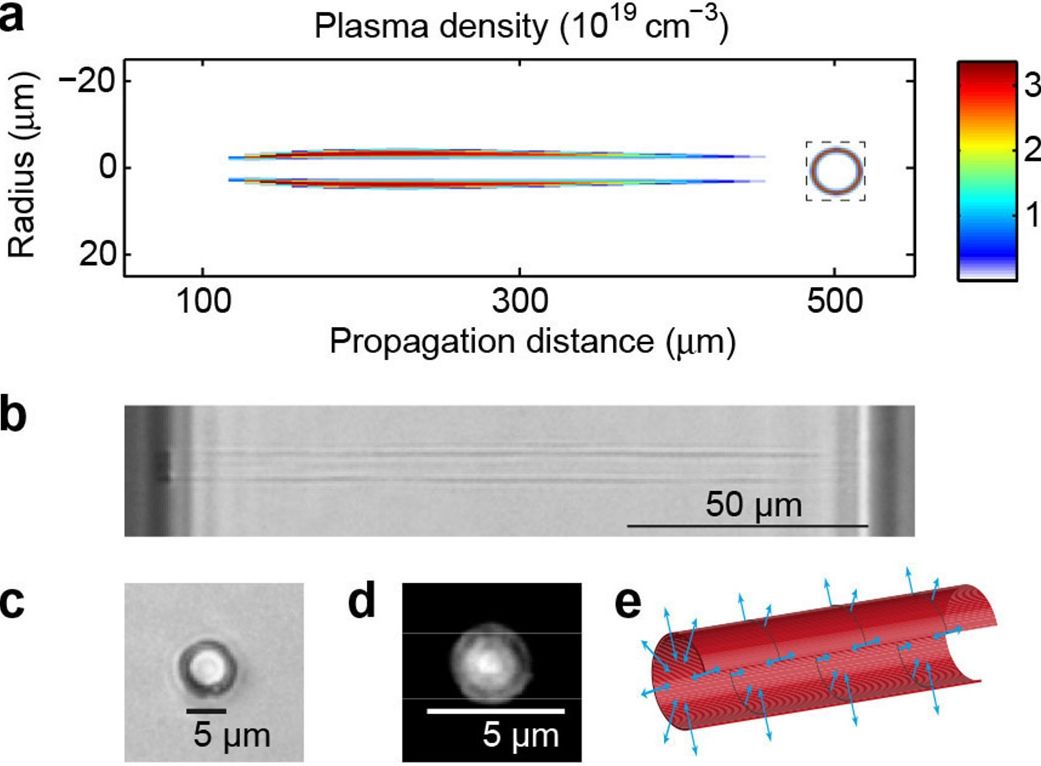

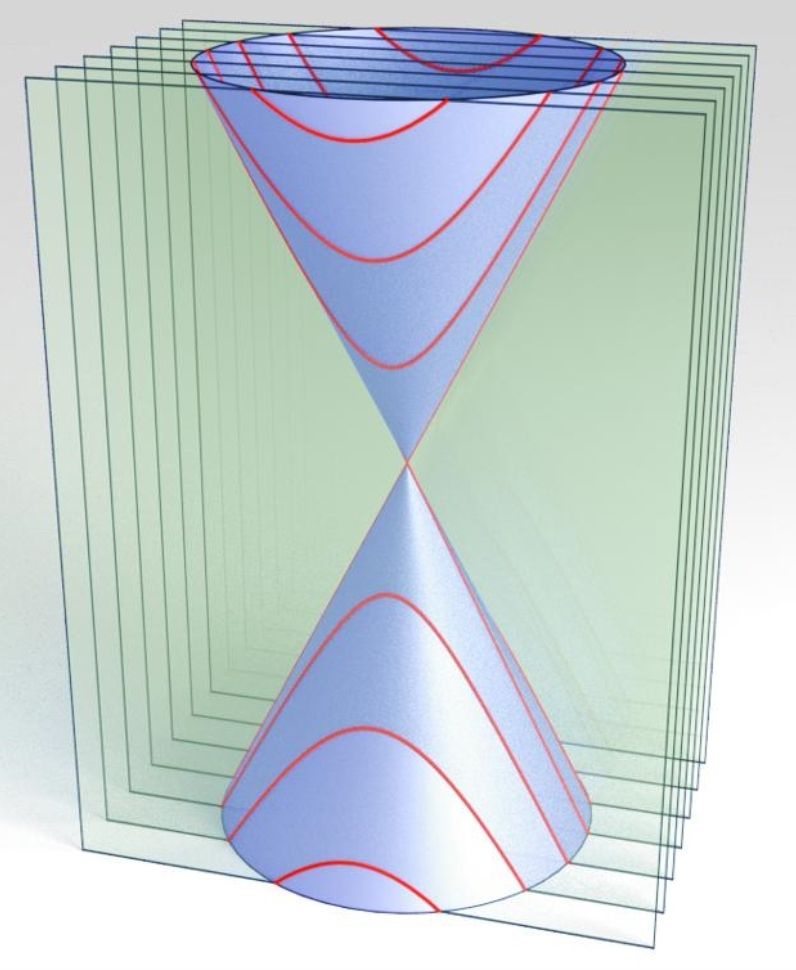

Tiny defects in perovskite’s crystalline structure can hamper the conversion of light into electricity in a solar cell, but “what we’re finding is that there are some defects that can be healed under light,” says Stranks, who is a Marie Curie Fellow jointly at MIT and Cambridge University in the U.K. The tiny defects, called traps, can cause electrons to recombine with atoms before the electrons can reach a place in the crystal where their motion can be harnessed.