In less than 4 yrs. 5 million jobs will be lost is the prediction.

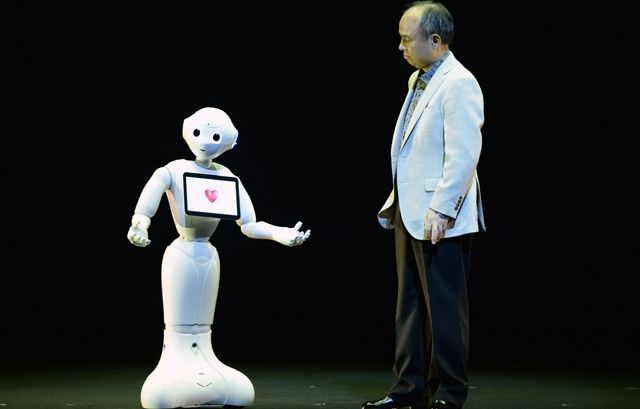

A new report predicts a loss of 5 million jobs in the next five years because of technological advances, but don’t blame it all on the robots.

The other culprits: artificial intelligence, 3-D printers and advances in genetics, biotech and more.

The World Economic Forum, which is holding its annual meeting in Davos this week, in its report details the effects of modern technology on the labor market, for better or for worse. It says “the fourth industrial revolution” will be “more comprehensive and all-encompassing than anything we have ever seen.”

Read more