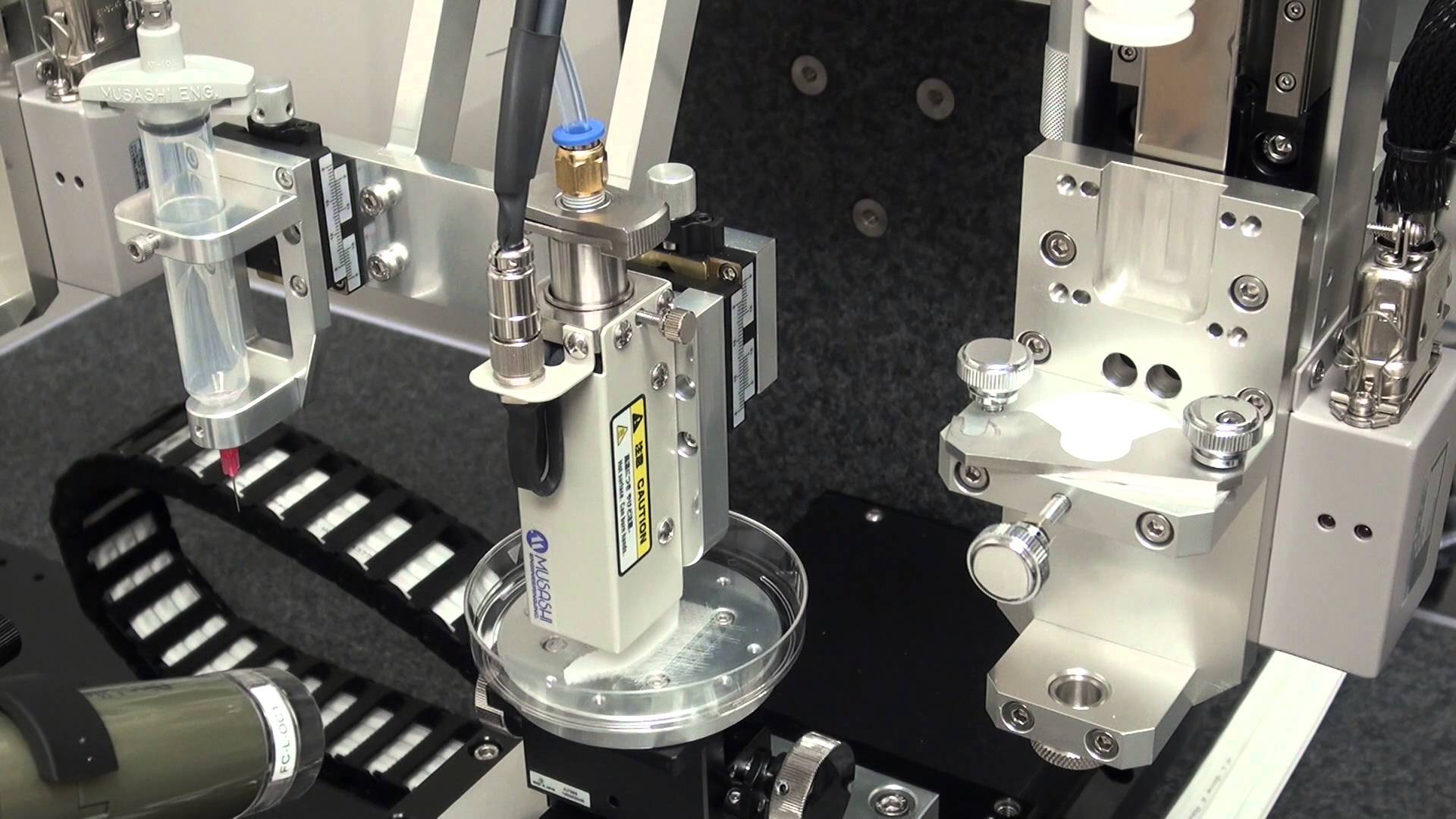

After 10 years of development, the Wake Forest Institute of Regenerative Medicine has finally unveiled a 3D printer that can craft simple tissues, such as cartilage, into complex shapes suitable for implantation.

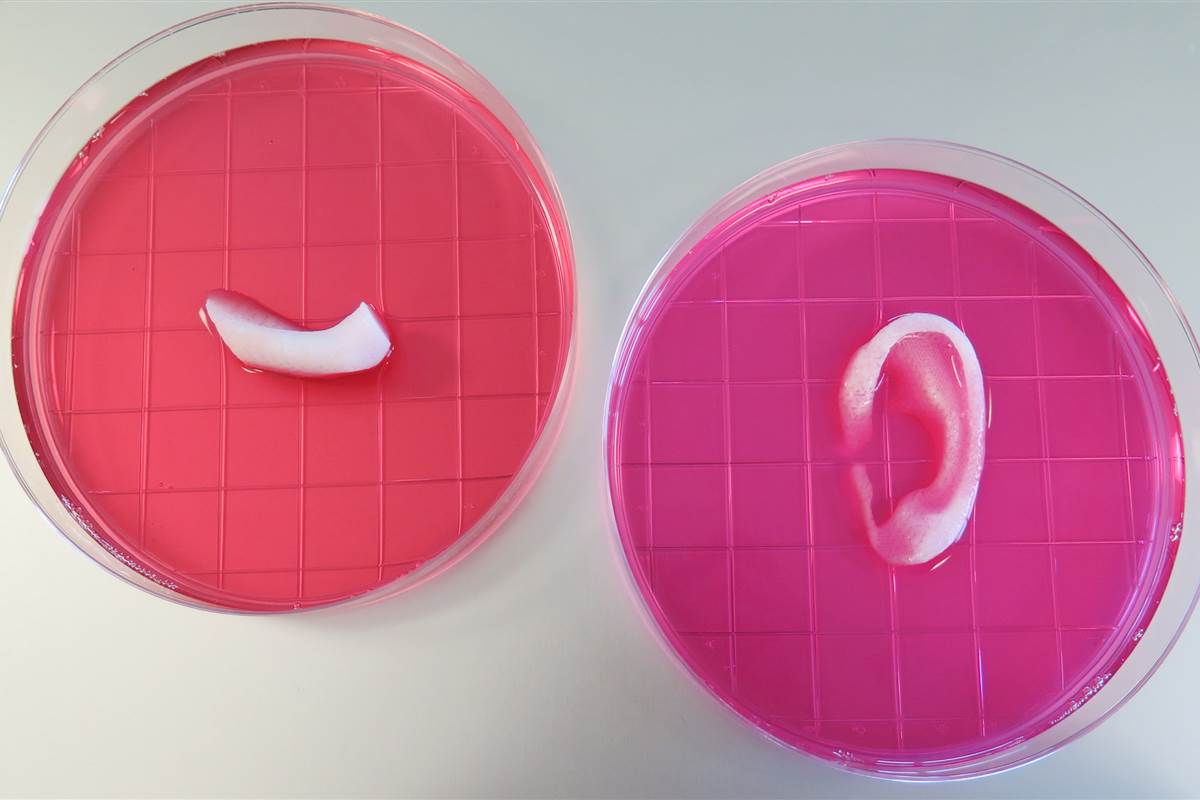

The printer uses cartridges filled with biodegradable plastic and human cells bound in gel form, and it can grow muscle, cartilage, and even bone. When implanted into animals, these crafted tissues have been shown to survive and even thrive for an indefinite amount of time.

“This is the first [bioprinter] that can print tissue at the large scales relevant for human implantation,” lead scientist behind the project, Anthony Atala, says in the release. “Basically, once we’ve printed a structure, we can keep it alive for several weeks before we implant it. Now the next step is to test these [printed tissues] for safety so we can implant them in the future in patients.”