“Researchers Successfully Implant Living, Functional 3D Printed Human Tissue Into Animals”

My question is “why?”

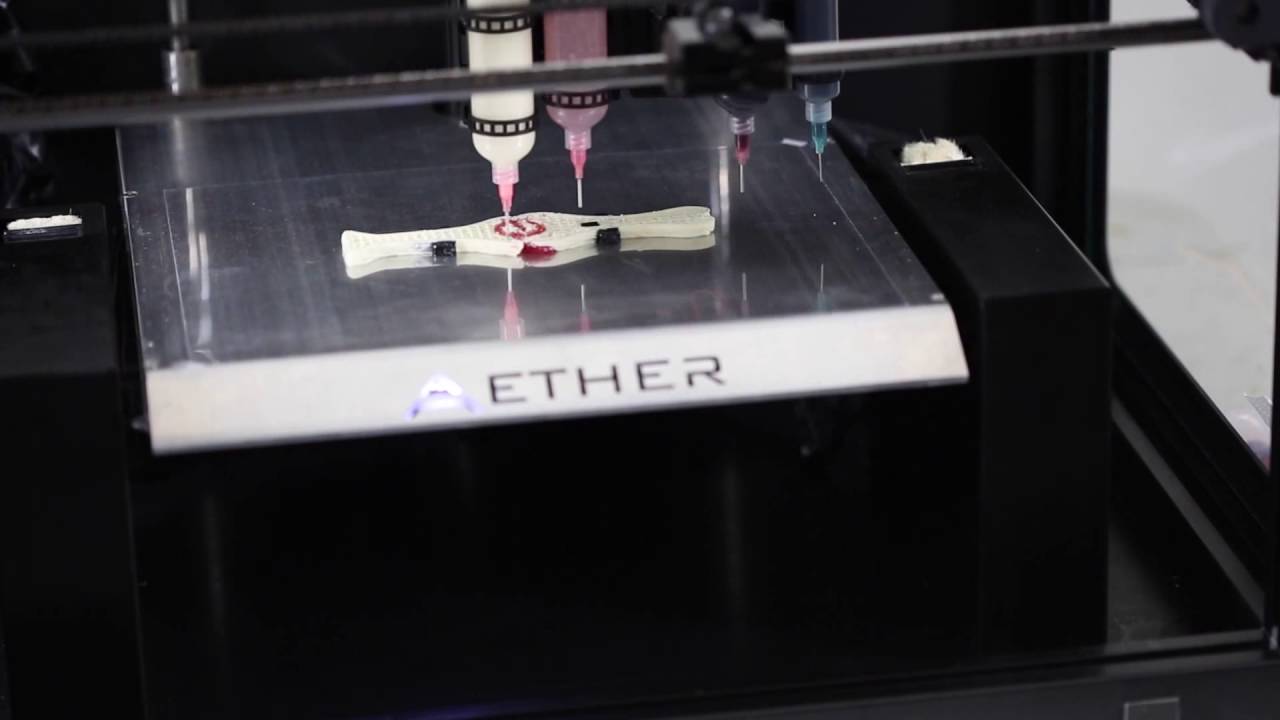

The news has been full of stories about new advancements in 3D printed tissue. Companies such as Organovo and research institutions such as the University of California San Diego are leading the charge in the development of 3D printed, functional human tissue, particularly liver tissue. So far, printed tissue is being used mostly for pharmaceutical drug testing, but everyone in the 3D printing biosphere professes the ultimate goal of eventually producing whole, fully functional human organs that can be transplanted into patients. Most experts agree that it will happen; it’s just a matter of when.

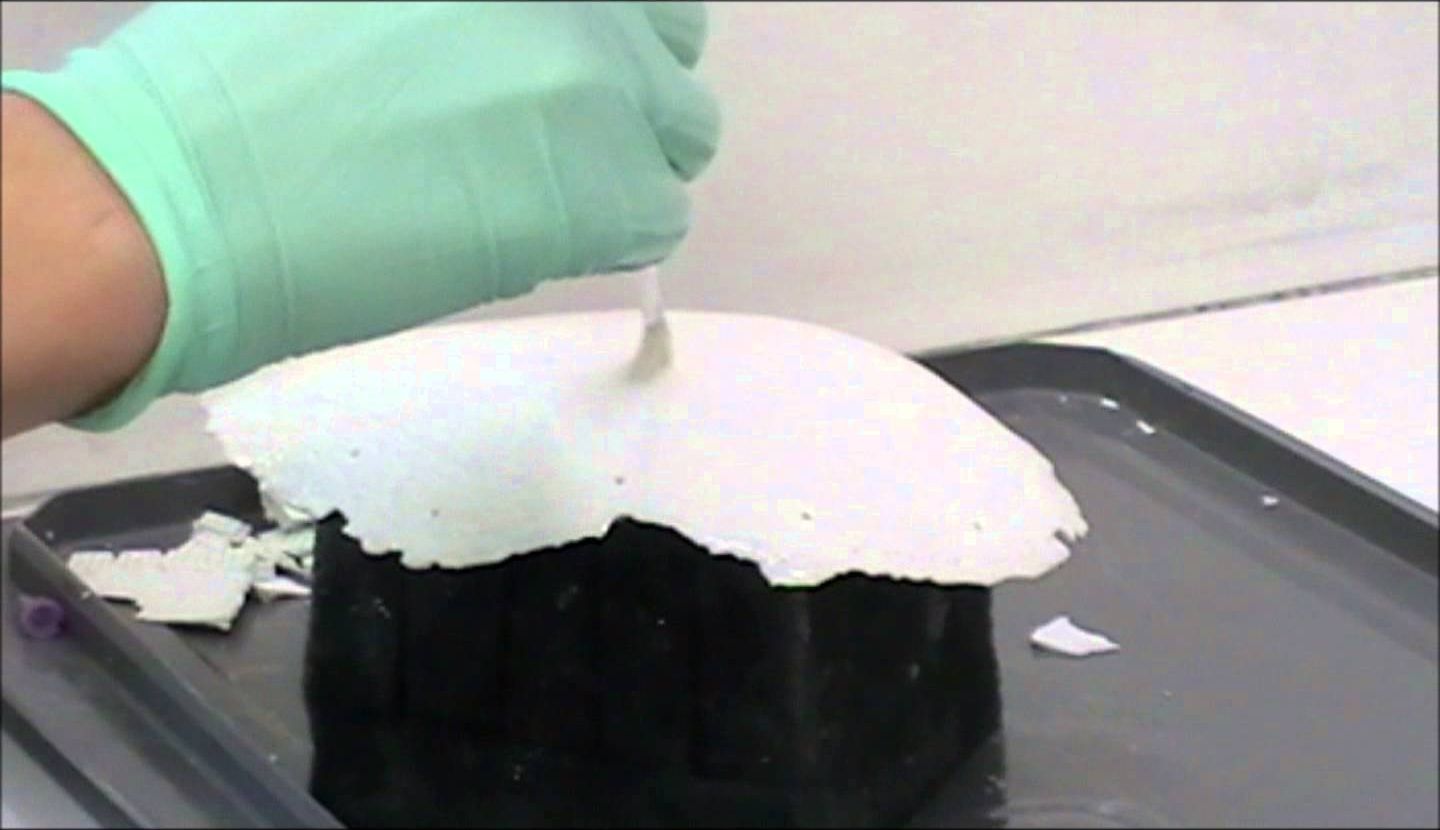

It’s also a matter of who. The race to be the first to 3D print a transplantable human organ is an intense one, and Wake Forest Baptist Medical Center may have just pulled into the lead. Regenerative medicine researchers at the North Carolina hospital have announced that they have printed ear, bone and muscle structures and successfully implanted them into animals. The structures, after being implanted, matured into functional tissue and sprouted new systems of blood vessels, and their strength and size mean that they could feasibly be implanted into humans in the future.