Self printed, self healing houses now possible.

Disrupted Commentary.

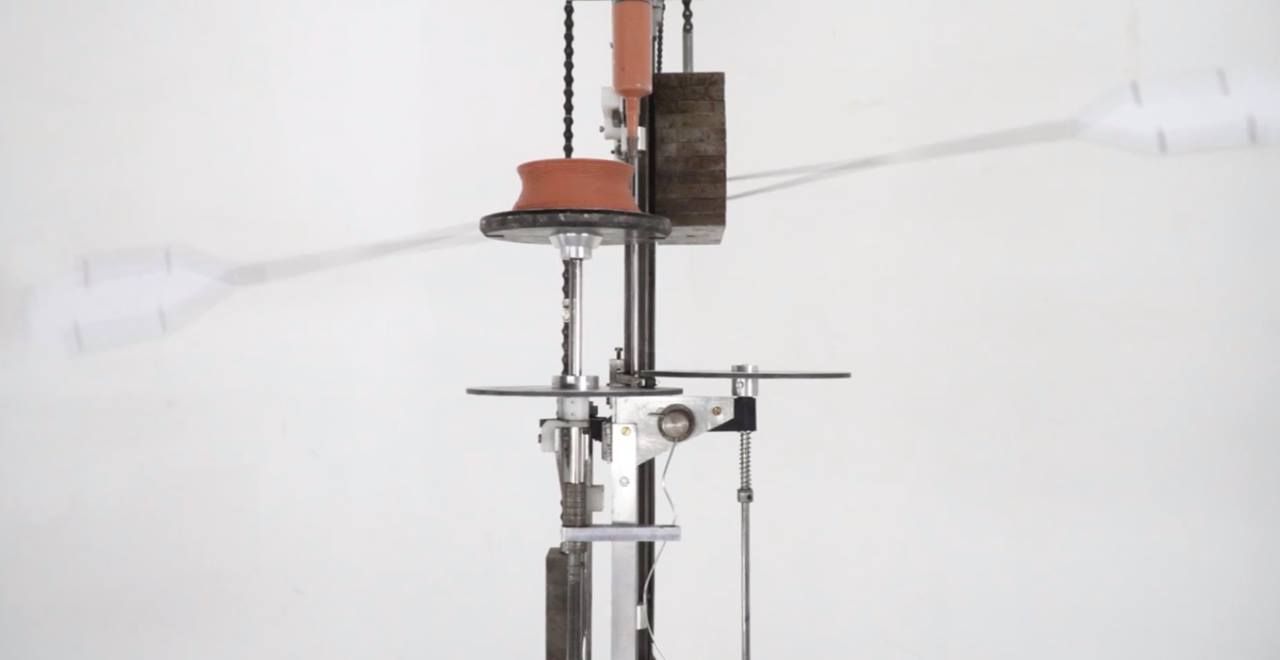

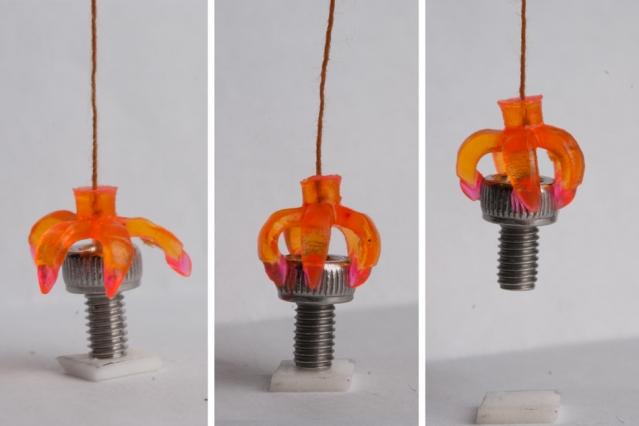

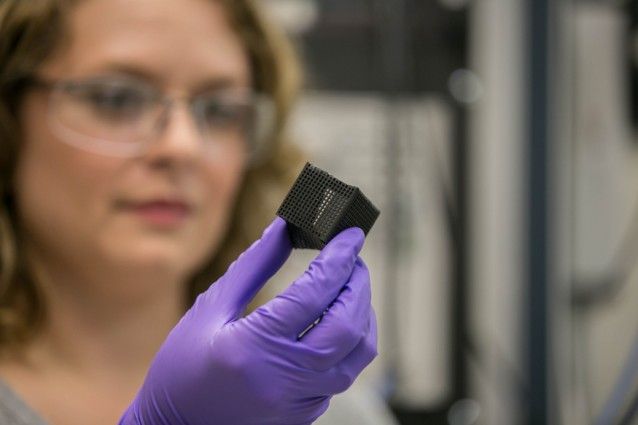

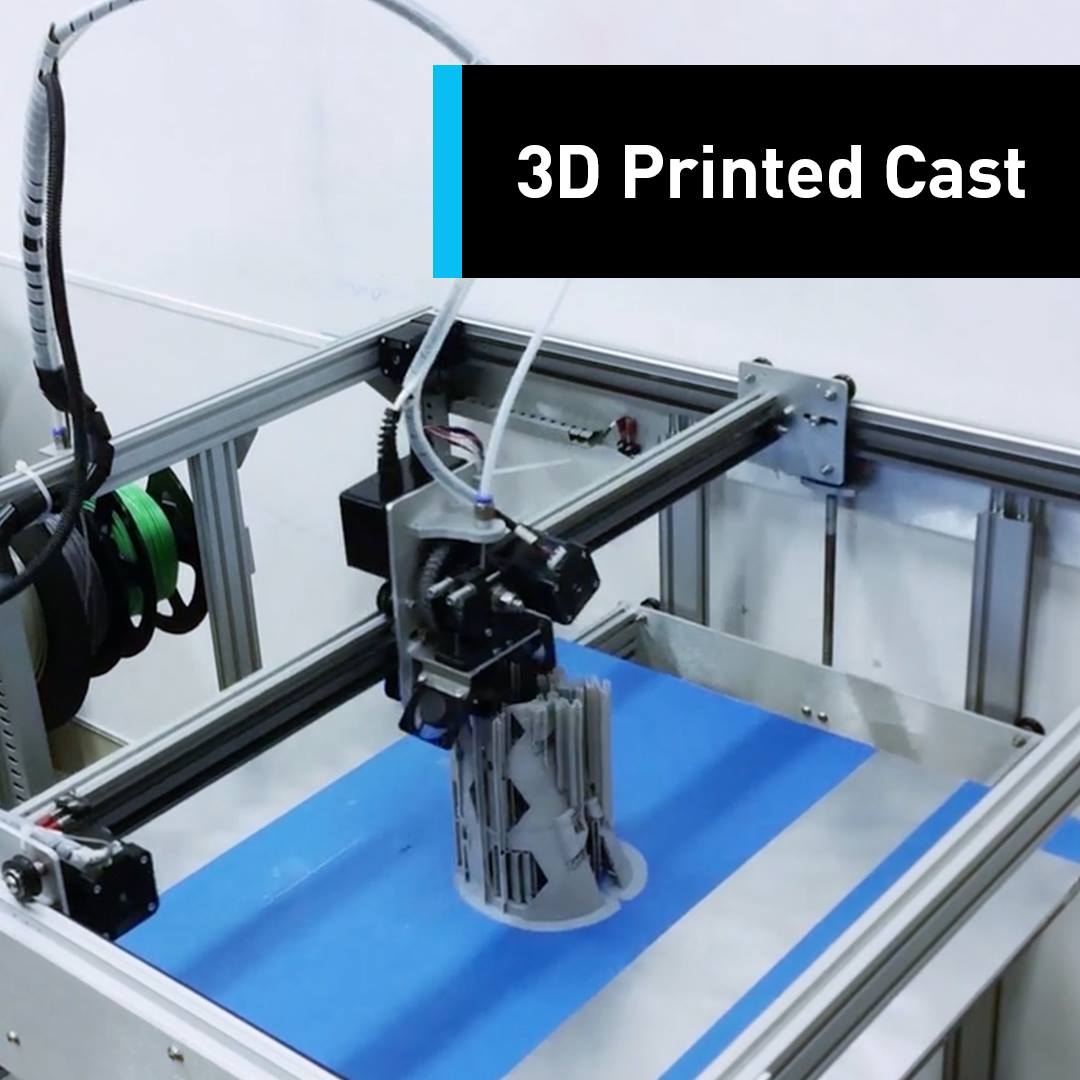

We’ve been writing about the positive disruption potentially caused by 3D printing since we started this blog in 2014. The key to making it commercial viable has been materials science developments and such is the rate of advance 3D printing is now being used to print car parts. Now we’re moving into materials science that allows self healing buildings – from 3dprint; “Magic is a recurring thing in the 3D printing industry. It’s quite challenging—and exhilarating all at once—the first time you put one of the machines into action for yourself, watching a project go from start to finish. To see that you can decide on something you want, and then have it appear in front of you is startling, euphoria-inducing, and downright addicting. Add to that the sheer simplicity of how it all works, and the brain is further boggled. But none of this compares to the true magic of this technology—all emanating from human minds.