Category: 3D printing

Humanized organs in gene-edited animals

Humanized organs in gene-edited animals is one potential way medicine can deal with the demand for transplant organs.

One potential avenue for research and to help solve the organ shortage is to modify animals to be closer matched to humans in order to have organs capable of being used for transplant. This short paper is an interesting primer into the subject and touches upon the technical and ethical concerns involved here.

It is one possible solution to the problem, however, 3D bioprinting increases in sophistication and other methods are also being developed that would render this approach needless. Still this is an interesting insight into regenerative medicine and one possible path research might take.

#LifespanIO #aging #crowdfundthecure

http://www.futuremedicine.com/doi/10.2217/rme-2016-0096

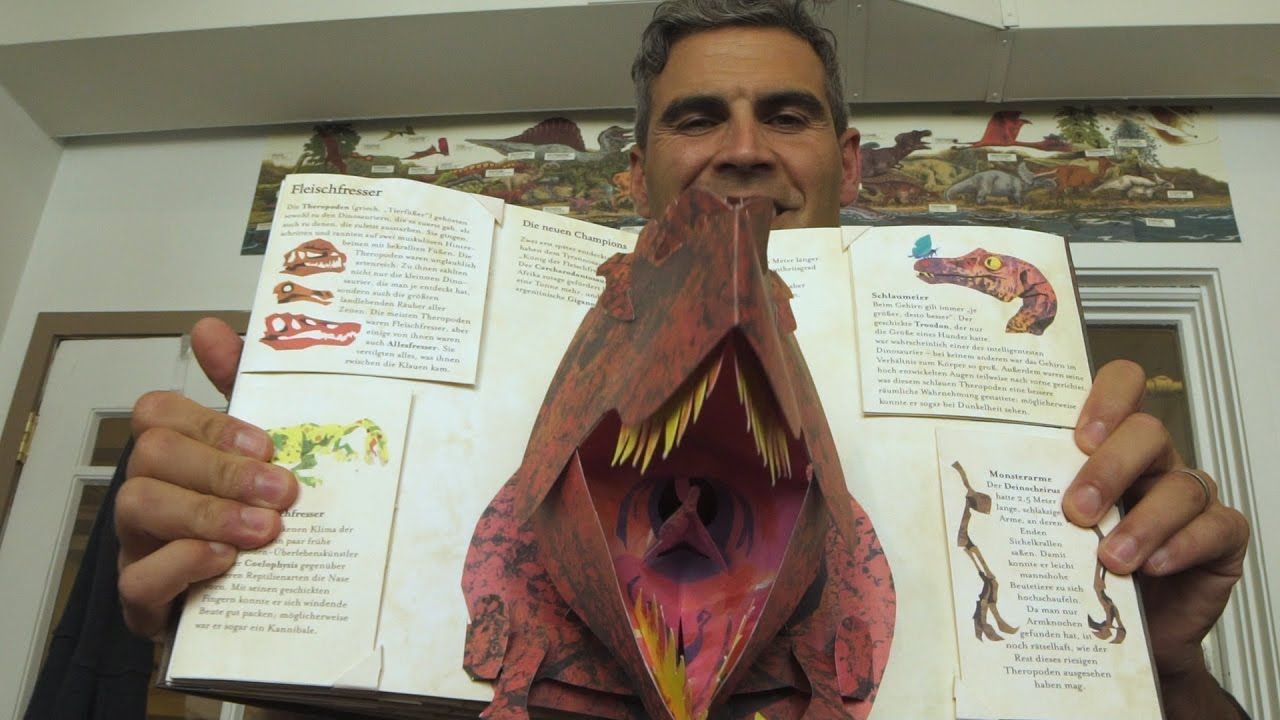

Why Duct Tape and Cardboard Might Be a Better Option than a 3D Printer

Another POV for 3D Printing.

This is the third post in a series on vintage learning.

A few days ago, I met Manuel Herrera at MORENet. He has an amazing maker space where students engage in creative thinking on a daily basis. It’s a bastion of creativity and wonder and his passion for it is contagious.

However, as we talked about prototyping and design thinking, he mentioned something surprising.

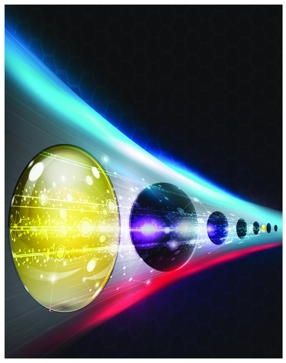

Diamonds aren’t forever: Sandia, Harvard team create first quantum computer bridge

Another article on the QC advancement; however, as I told folks synthetic diamonds are key plus the crystalized formation are proven to be very useful not only in QC processing; but also for the light-based (Quantum) networking. I see this only the beginning (as we have seen with Synthetic DNA data storage) for synthetic gem crystalize formations in their usage in technology. Hoping folks are checking out the 3D Printers creating these synthetics because we truly are on the path of seeing our world transform to new levels never imagined.

Abstract: By forcefully embedding two silicon atoms in a diamond matrix, Sandia researchers have demonstrated for the first time on a single chip all the components needed to create a quantum bridge to link quantum computers together.

“People have already built small quantum computers,” says Sandia researcher Ryan Camacho. “Maybe the first useful one won’t be a single giant quantum computer but a connected cluster of small ones.”

Distributing quantum information on a bridge, or network, could also enable novel forms of quantum sensing, since quantum correlations allow all the atoms in the network to behave as though they were one single atom.

Doctors Can Now 3D-Print Bones On Demand, Thanks to a New “Hyperelastic” Material

In Brief.

- New 3D printed bones are ‘hyperelastic,’ making them more malleable during procedures.

- 3D printers in hospitals could provide the hyperelastic bone ink, so surgeons could make implants in 24 hours.

Remarkable.

This best describes the new bone-mending technology developed at Northwestern University in Evanston, Illinois by Ramille Shah and her colleagues. They used ink made from a natural bone mineral called hydroxyapatite, mixed with PLGA, a mineral-binding polymer that makes the implants elastic.

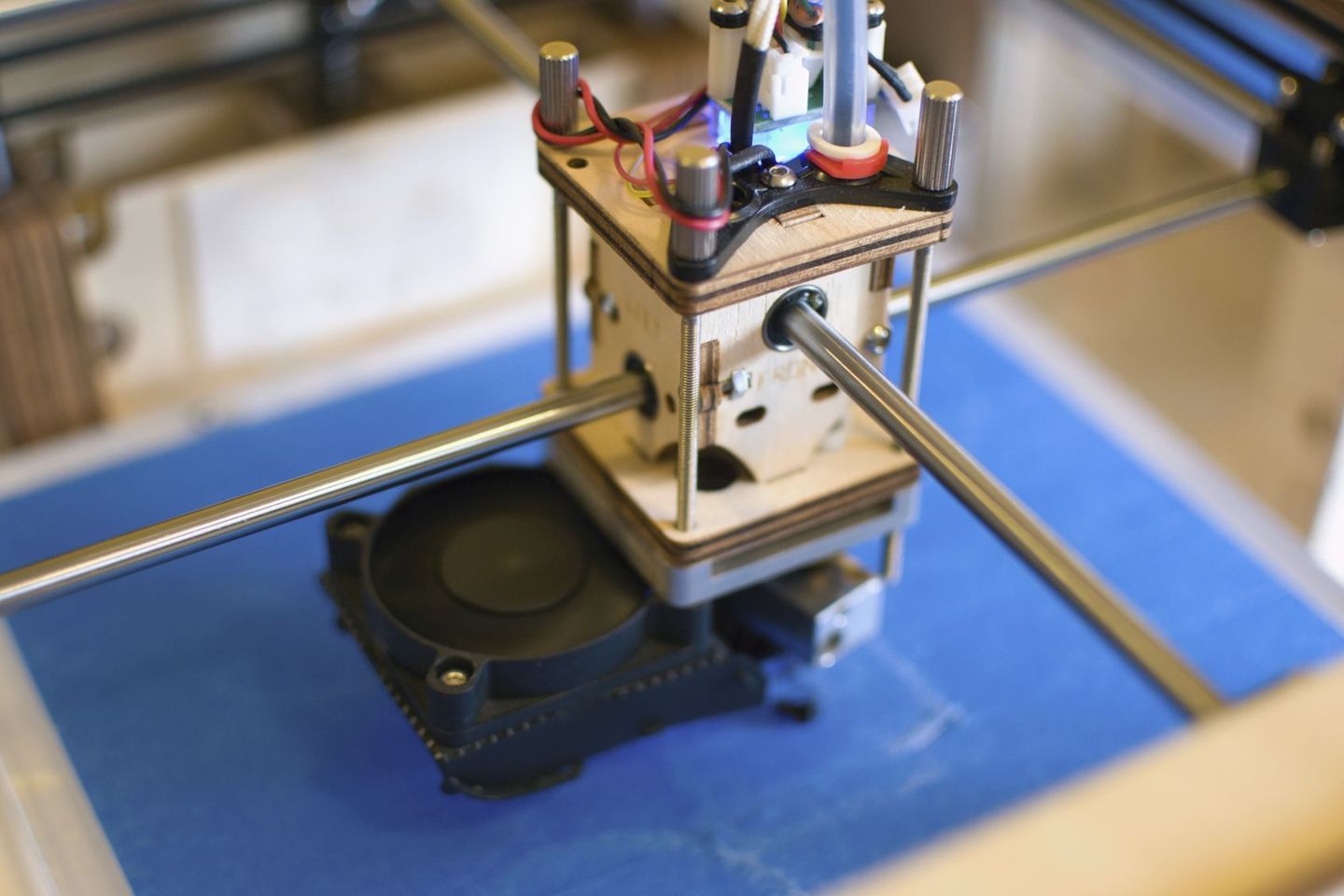

MIT applies soft touch to robots with programmable 3D-printed skins

Spectators of the DARPA Robotics Challenge finals in 2015 would have noticed that many of the competing robots were padded up for protection in case they took a tumble. MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) is looking to build customizable shock-absorbing protection into robots by using 3D printing to produce soft materials that not only dampen the impact of falls, but also allows them to carry out safer, more precise movements.

Robotics engineers have long had a keen interest in soft materials. At their simplest, such materials can protect robots against falls and collisions, but can also protect people in environments were robots and humans are increasingly working together. Going beyond this, soft materials also allow for making completely soft robots that can mimic animal design.

Using 3D printing technology, CSAIL is creating soft materials that can change the basic capabilities of the robot. Called programmable viscoelastic material (PVM), it’s based on the idea of controlling the stiffness and elasticity of a substance to change how it moves and responds. In this way, engineers can tailor the material for the task at hand.

Science, Technology, and the Future of Warfare

Nice POV read.

We know that emerging innovations within cutting-edge science and technology (S&T) areas carry the potential to revolutionize governmental structures, economies, and life as we know it. Yet, others have argued that such technologies could yield doomsday scenarios and that military applications of such technologies have even greater potential than nuclear weapons to radically change the balance of power. These S&T areas include robotics and autonomous unmanned system; artificial intelligence; biotechnology, including synthetic and systems biology; the cognitive neurosciences; nanotechnology, including stealth meta-materials; additive manufacturing (aka 3D printing); and the intersection of each with information and computing technologies, i.e., cyber-everything. These concepts and the underlying strategic importance were articulated at the multi-national level in NATO’s May 2010 New Strategic Concept paper: “Less predictable is the possibility that research breakthroughs will transform the technological battlefield … The most destructive periods of history tend to be those when the means of aggression have gained the upper hand in the art of waging war.”

As new and unpredicted technologies are emerging at a seemingly unprecedented pace globally, communication of those new discoveries is occurring faster than ever, meaning that the unique ownership of a new technology is no longer a sufficient position, if not impossible. They’re becoming cheaper and more readily available. In today’s world, recognition of the potential applications of a technology and a sense of purpose in exploiting it are far more important than simply having access to it.

While the suggestions like those that nanotechnology will enable a new class of weapons that will alter the geopolitical landscape remain unrealized, a number of unresolved security puzzles underlying emerging technologies have implications for international security, defense policy, deterrence, governance, and arms control regimes.

3D printing grows up: scientists are using the tech to make an earthmoving machine

Scientists at the US Oak Ridge National Laboratory are assembling the world’s first 3D-printed hydraulic excavator, a prototype which they say will explore the feasibility of printing with metal alloys.

3D-printing, or additive manufacturing (AM), mostly uses plastics of some sort to create objects layer by layer. Plastics are cheap, light, and easy to melt, lending themselves to the process. Metals, on the other hand, are heavy, costly, and melt at much higher temperatures – making them a challenging material for 3D printing.

But metals are what is needed if truly useful machines like cars or tractors are to be 3D-printed.

Promising biomaterial to build better bones with 3D printing

A Northwestern Engineering research team has developed a 3D printable ink that produces a synthetic bone implant that rapidly induces bone regeneration and growth. This hyperelastic “bone” material, whose shape can be easily customized, one day could be especially useful for the treatment of bone defects in children.

Bone implantation surgery is never an easy process, but it is particularly painful and complicated for children. With both adults and children, often times bone is harvested from elsewhere in the body to replace the missing bone, which can lead to other complications and pain. Metallic implants are sometimes used, but this is not a permanent fix for growing children.

“Adults have more options when it comes to implants,” said Ramille N. Shah, who led the research. “Pediatric patients do not. If you give them a permanent implant, you have to do more surgeries in the future as they grow. They might face years of difficulty.”