The Archinaut, a system made of 3D printers and robotic arms, could be the flying factory humans need to colonize space.

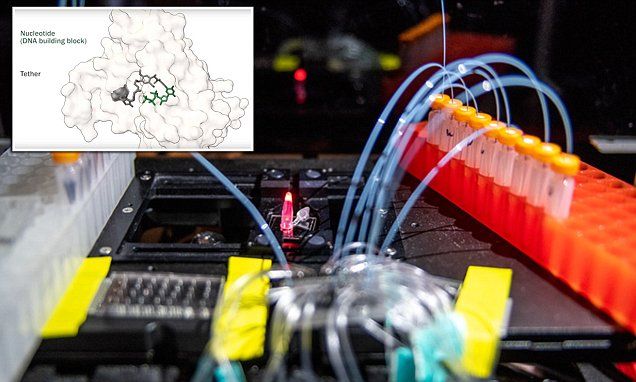

A revolutionary new DNA tool could help take humanity a step closer to eternal life. The device (pictured) pioneers a new technique that makes it cheaper and easier to synthesise genes ‘overnight’, say scientists — a process that normally takes several days.

Scientists at the University of California at Berkeley said it could lead to ‘DNA printers’ in research labs that work like the 3D printers in many modern workshops.

‘If you’re a mechanical engineer, it’s really nice to have a 3D printer in your shop that can print out a part overnight so you can test it the next morning,’ said UC Berkeley graduate student Dan Arlow.

https://youtube.com/watch?v=wvwXgZhrr-s

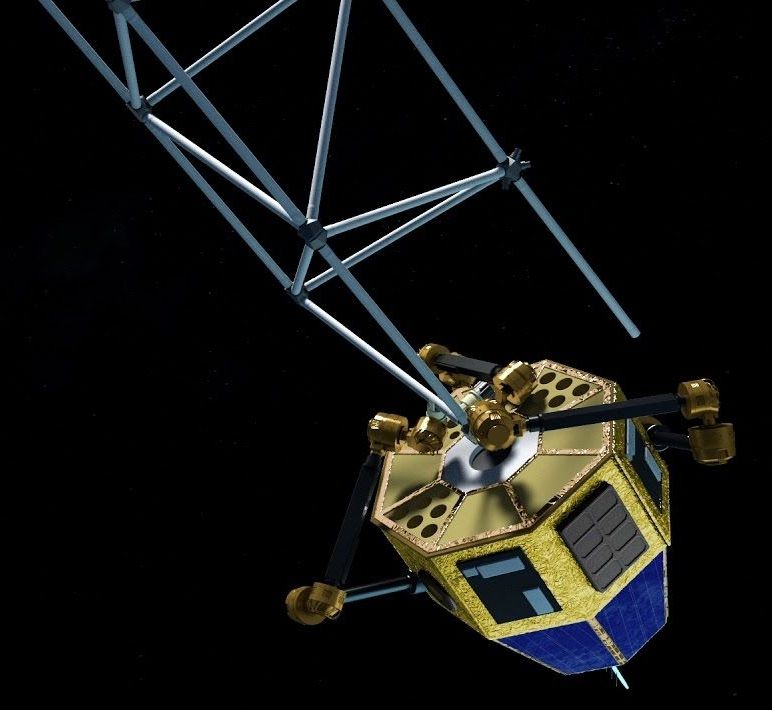

A spacecraft, spinning in Earth’s orbit, reaches inside itself. One of its four arms pulls out a length of polymer pipe that has been 3D-printed inside the body of the machines. All four of the spacecraft’s arms are securing pieces together as it builds a new space station right there in orbit.

This surreal project, called Archinaut, is the future vision of space manufacturing company Made In Space. The company promises a future of large imaging arrays, kilometer-scale communications tools, and big space stations all built off-planet by smart robots.

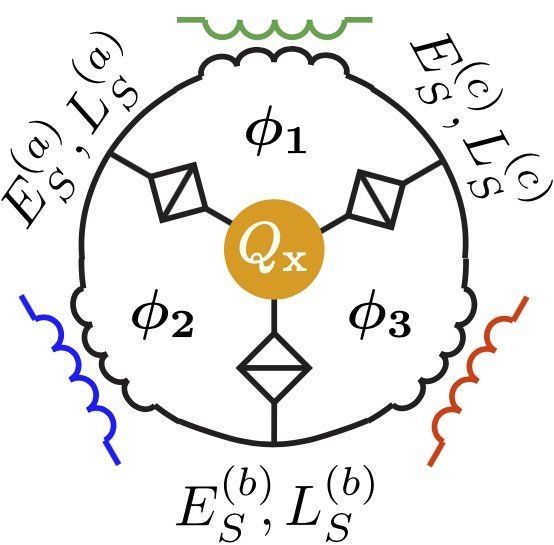

It was a good week for physics as a team with members from Australia and Switzerland invented a flux capacitor able to break time-reversal symmetry. They proposed a device based on quantum tunneling of magnetic flux around a capacitor. And another team with members from across the U.S. reported on a gravitational wave event that likely signaled the creation of a black hole—the merger of two neutron stars.

In biology news, a team of engineers led by Sinisa Vukelic invented a noninvasive technique to correct vision. Like LASIK, it uses lasers but is non-surgical and has few side-effects. And an international team of researchers found what they describe as the mother of all lizards in the Italian Alps, the oldest known lizard fossil, from approximately 240 million years ago. Also, a team at the University of Sydney found that walking faster could make you live longer. People do not even need to walk more, the team reported, they just need to pick up the pace of their normal stride to see an improvement in several health factors. And a team from Cal Poly Pomona discovered how microbes survive clean rooms and contaminate spacecraft—and it involved the cleaning agents themselves.

In other news, a team of researchers from the University of California and the University of Southern Queensland announced that they had identified 121 giant planets that may have habitable moons. And a team at Stanford University found that wars and clan structure might explain a strange biological event that occurred 7,000 years ago—male genetic diversity appeared to collapse for a time. Also, a team of researchers from MIT and Harvard University report the development of a 3D printer that can print data sets as physical objects—offering far more realistic, nearly true-color renderings.

60 days.

That’s how long it will take to produce and launch a rocket if the parts are 3D printed, according to the CEO of Relativity Space, a startup that seeks to do just that.

Flying something made completely of 3D-printed parts into space sounds, frankly, pretty bonkers. But investors are on board. The Los Angeles-based startup recently secured $35 million to go ahead with its plan to produce a fleet of spacecraft using one of the largest 3D printers known to man, known as Stargate.

The Dutch city of Eindhoven is to host the world’s first commercial housing project based on 3D-concrete printing, with the first of five planned houses due to start construction this year. The units were developed by a collaborative team including the Eindhoven University of Technology and will be purchased and let out by a real estate company upon completion.

The first house will be a single-floor, three-room house measuring 1000 square feet (95 square meters), to be followed by four multi-story units. The irregular shape of the buildings is based on “erratic blocks in the green landscape,” made possible due to the flexibility of form permitted by 3D-printing.

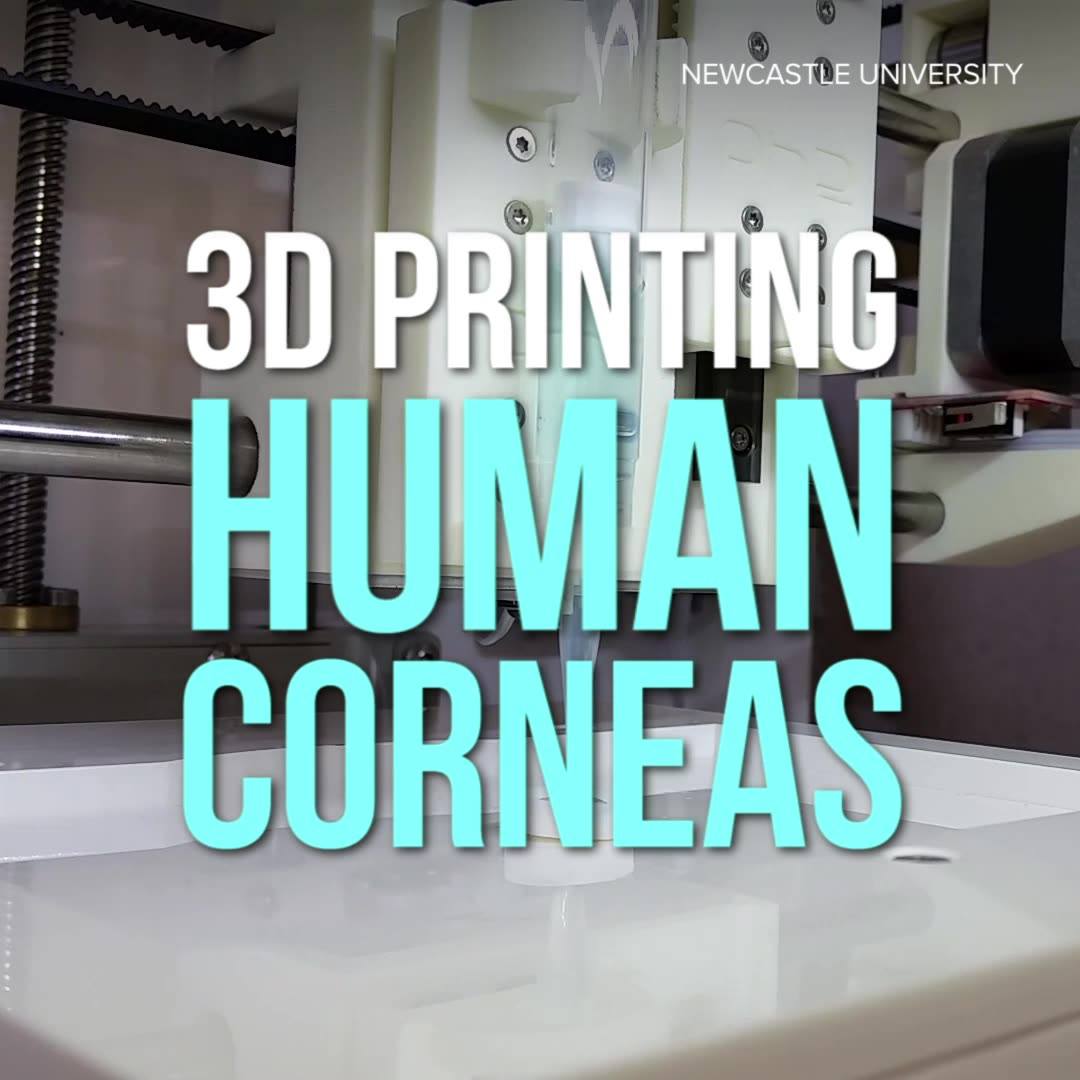

The human eye is a remarkably sophisticated organ and like the lens to a camera, it’s the cornea that focuses the flood of photons into a perceptible image. But for an estimated 15 million people around the world, eye disease and trauma make surgery the only path to clear vision.

In the next few years, artificial corneas may become more accessible thanks to new research out of Newcastle University in the United Kingdom. There, researchers mixed stem cells from the cornea of a healthy donor with collagen and algae molecules to create a bio-ink, which they 3D-printed into an artificial cornea. The research is currently just a proof-of-concept but lays the groundwork for future techniques to create low-cost, easy-to-produce bionic eyes.

There were three features required for the bio-ink, according to Che Connon, a professor of tissue engineering at Newcastle.

https://www.engadget.com/…/3D-printed-brain-medical-imagin…/

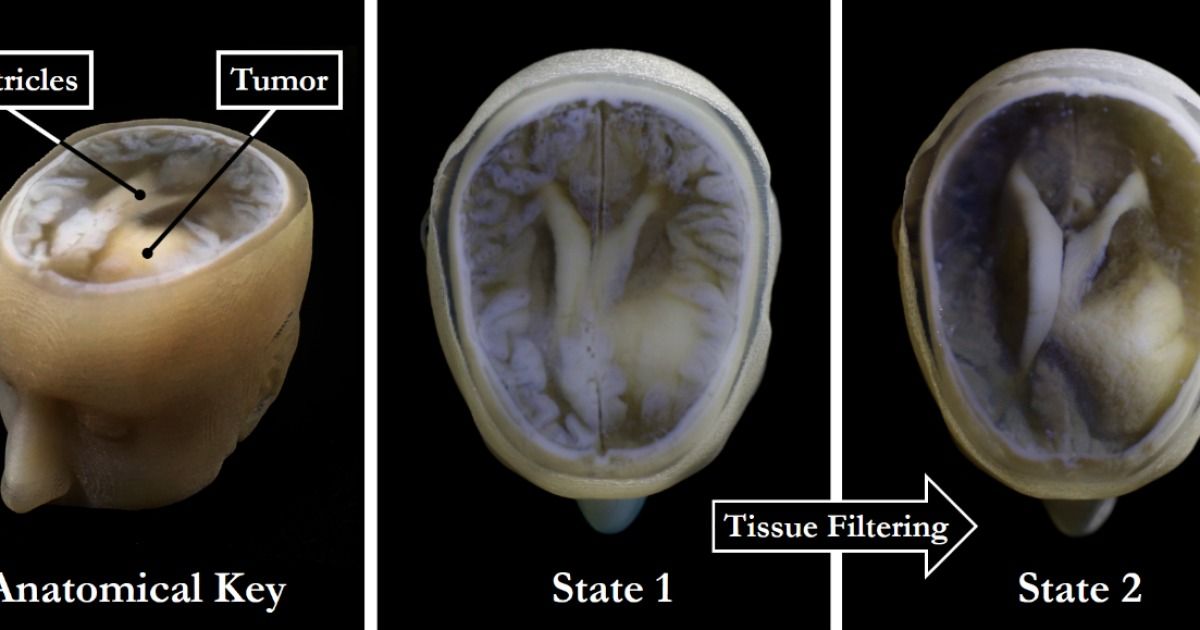

There are almost limitless possibilities when it comes to 3D printing. Design your own color-changing jewelry? Fine. Fabricate your own drugs? No problem. Print an entire house in under 24 hours? Sure! Now, researchers have come up with a fast and easy way to print palm-sized models of individual human brains, presumably in a bid to advance scientific endeavours, but also because, well, that’s pretty neat.

In theory, creating a 3D printout of a human brain has been done before, using data from MRI and CT scans. But as MIT graduate Steven Keating found when he wanted to examine his own brain following his surgery to remove a baseball-sized tumour, it’s a slow, cumbersome process that doesn’t reveal any important areas of interest.

MRI and CT scans produce images with so much detail that objects of interest need to be isolated from surrounding tissue and converted into surface meshes in order to be printed. This involves a radiologist manually tracing the desired object onto every single image “slice” of the brain, or it can be done via automatic thresholding, where a computer converts areas that contain grayscale pixels into either solid black or solid white pixels, based on a shade of gray that is chosen to be the threshold between black and white. But since medical imaging data often contains irregularly-shaped objects and lacks clear borders, features of interest are usually over- or under-exaggerated, and details are washed out.