3D printing refers to various processes used to manufacture three dimensional objects in successive layers of material formed under computer control.

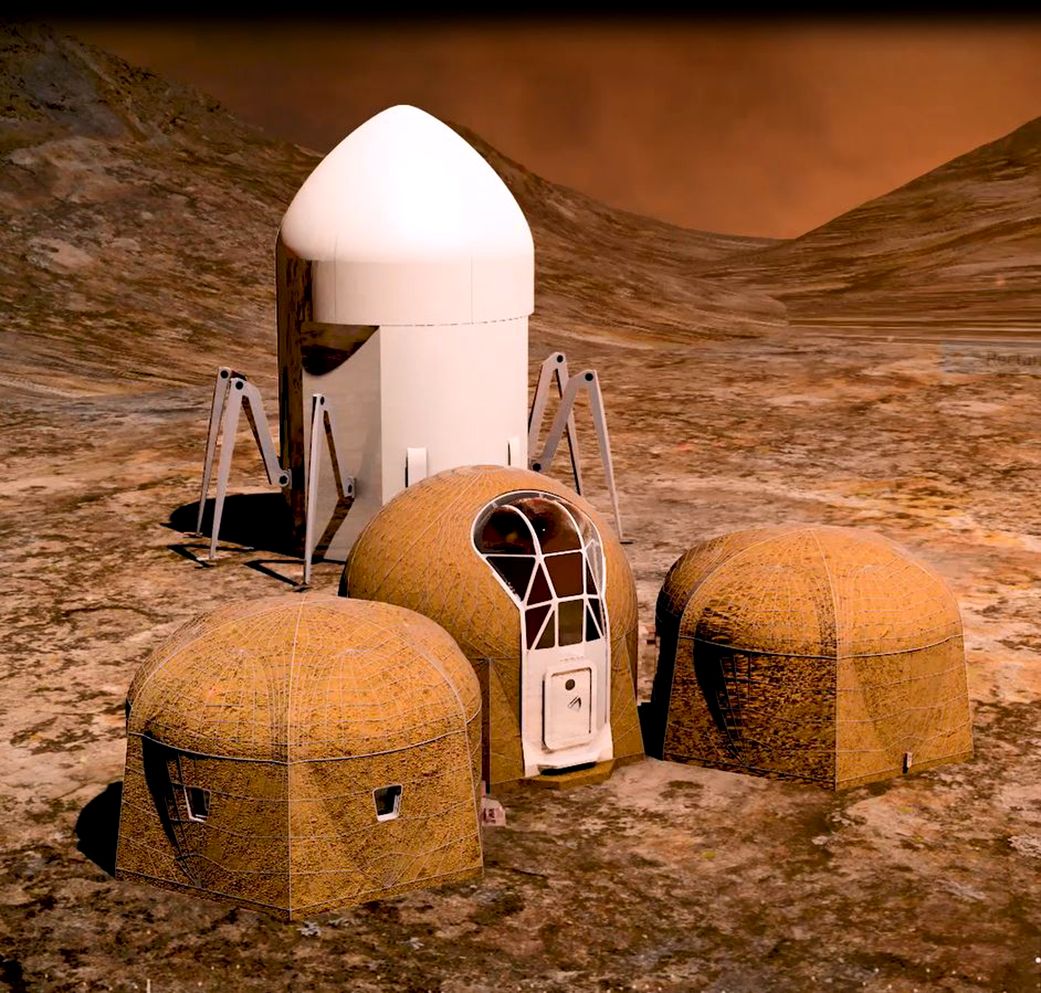

NASA-awarded ‘marsha’, a 3D-printed vertical Martian habitat by AI spacefactory.

3D printing refers to various processes used to manufacture three dimensional objects in successive layers of material formed under computer control.

NASA-awarded ‘marsha’, a 3D-printed vertical Martian habitat by AI spacefactory.

NASA and partner Bradley University of Peoria, Illinois, have selected the top five teams to share a $100,000 prize in the latest stage of the agency’s 3D-Printed Habitat Centennial Challenge competition. Winning teams successfully created digital representations of the physical and functional characteristics of a house on Mars using specialized software tools. The teams earned prize money based on scores assigned by a panel of subject matter experts from NASA, academia and industry. The judges interviewed and evaluated submissions from 18 teams from all over the world and selected these teams:

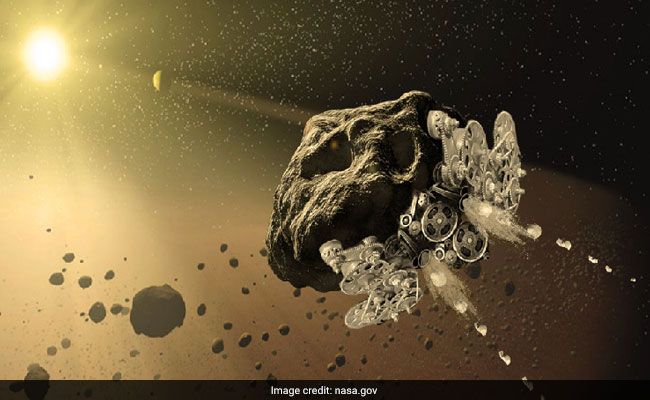

NASA has recently announced it would give funds to a California-based 3D printing company for finding ways to turn asteroids into giant, autonomous spacecrafts, which could fly to outposts in space, the media reported.

Made In Space’s project, known as RAMA (Reconstituting Asteroids into Mechanical Automata), could one day enable space colonization by helping make off-Earth manufacturing efficient and economically viable, Space.com reported.

The company plans to use 3D printing to turn the asteroids into self-flying vehicles by 2030.

The power of 3D printing has opened up a whole new mode of “imagination engineering.” The world of tomorrow’s weapons and ammunition are going to be radically different from what we consider weapons and ammunition today.

Now that Defense Distributed has won their court case, officially legalizing 3D-printable gun uploads and downloads, how will the future respond to today’s gun laws?

For some months now, a 3D printed house in Nantes has drawn lots of attention, not just because a printer was involved but also because it went up from start to finish so quickly (54 hours to print, then add some more time for the windows and roof). Interesting Engineering said it took some more time to add the roof, windows and doors.

A robot printer was used to print layers from the floor upwards to form the walls, and videos show a beautiful result of five rooms with rounded walls.

Now comes the latest news of the world’s first family to move into a 3D-printed home—that is now home for the Ramdani family, consisting of the two parents and their 3 children, to enjoy life in the 4-bedroom house in Nantes, France.

DENVER, July 11, 2018 /PRNewswire/ — Lockheed Martin (NYSE: LMT) has embraced a 3D printed titanium dome for satellite fuel tanks so big you can’t even put your arms around it. The 46-inch- (1.16-meter-) diameter vessel completed final rounds of quality testing this month, ending a multi-year development program to create giant, high-pressure tanks that carry fuel on board satellites.

The titanium tank consists of three parts welded together: two 3D printed domes that serve as caps, plus a variable-length, traditionally-manufactured titanium cylinder that forms the body.