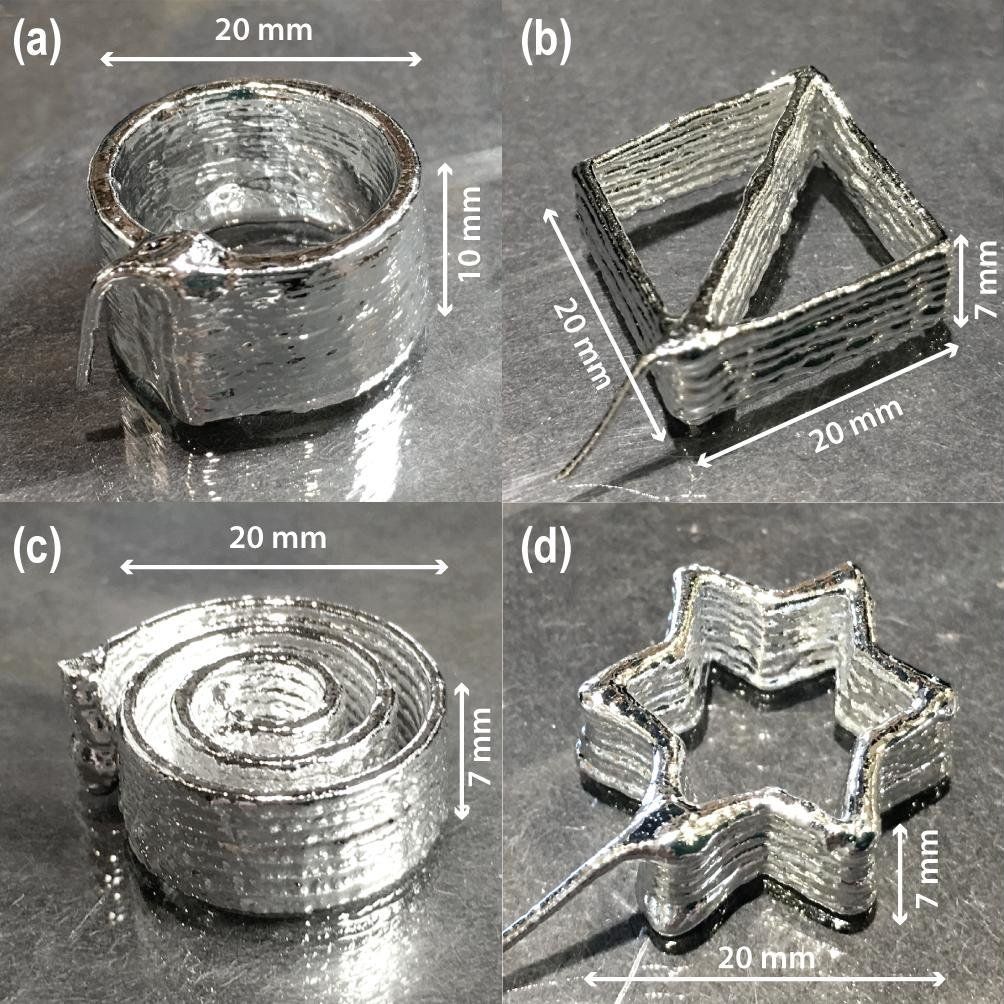

These 3D printed muscles are 3X stronger than real muscles!

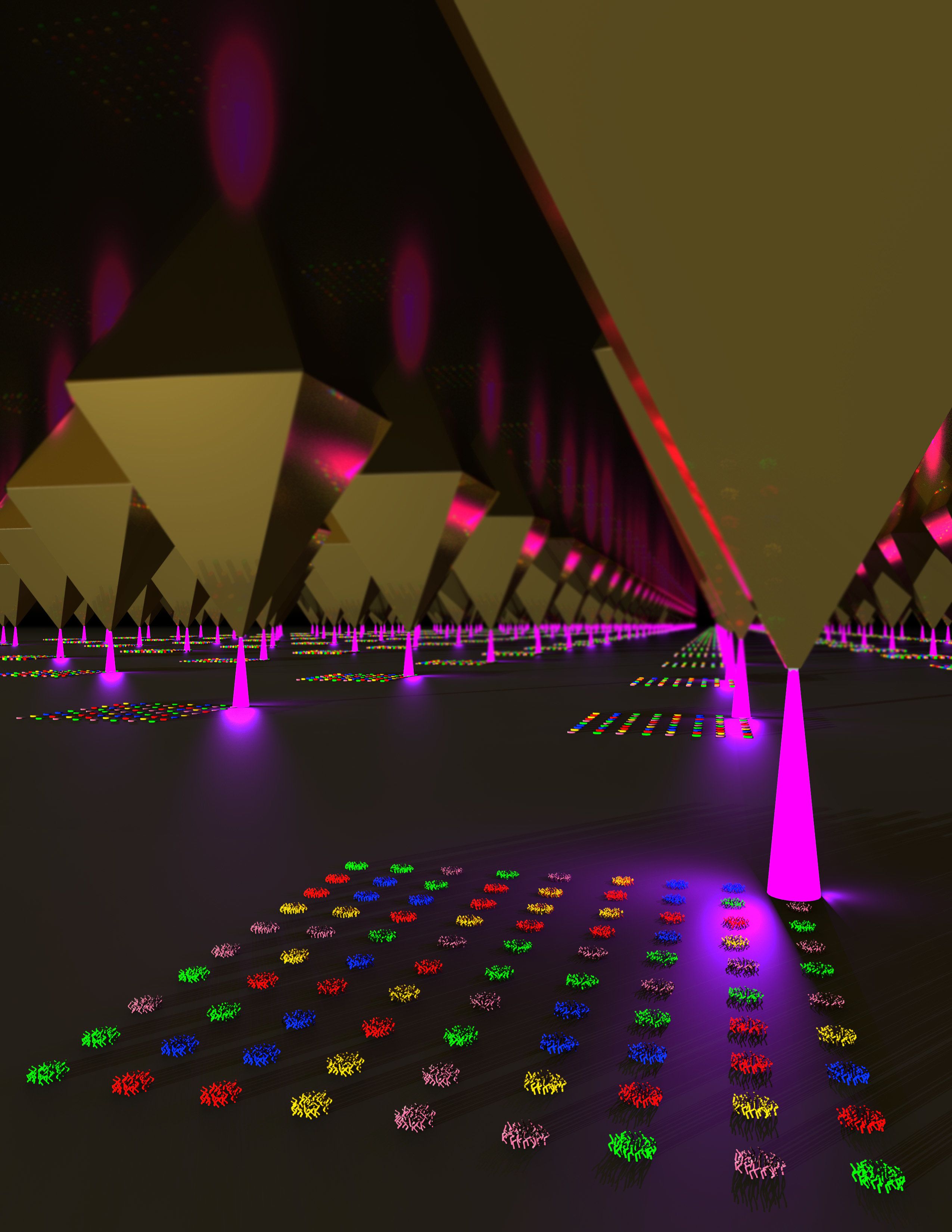

Researchers in Oregon State University’s College of Engineering have taken a key step toward the rapid manufacture of flexible computer screens and other stretchable electronic devices, including soft robots.

The advance by a team within the college’s Collaborative Robotics and Intelligent Systems Institute paves the way toward the 3D printing of tall, complicated structures with a highly conductive gallium alloy.

Researchers put nickel nanoparticles into the liquid metal, galinstan, to thicken it into a paste with a consistency suitable for additive manufacturing.

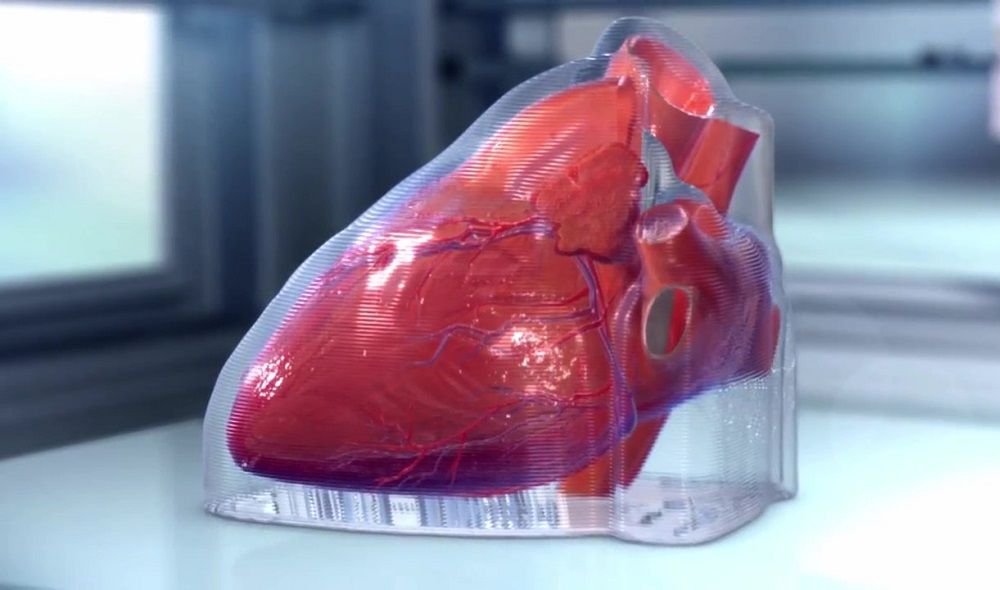

Summary: A startup wants to develop bioprinted beating hearts using stem cells from a patient’s own body using a special 3D bioprinter. [This article first appeared on LongevityFacts. Author: Brady Hartman. ]

A startup called BioLife4D wants to develop bioprinted beating hearts using a patient’s own cells as solution for patients seeking heart transplants.

As first reported on USAToday, Steven Morris, the CEO founding partner and of BioLife4D says that if the bioprinted heart is successful, the company hopes to expand to other organs including the pancreas or the kidneys.

3D printing has gained popularity in recent years as a means for creating a variety of functional products, from tools to clothing and medical devices. Now, the concept of multi-dimensional printing has helped a team of researchers at the Advanced Science Research Center (ASRC) at the Graduate Cent…

In 2016, a new Guinness World Record was set for the largest object to be 3D printed in one piece. The ABS/carbon fiber composite tool was 3D printed in 30 hours, and measured 17.5 feet long, 5.5 feet wide, and 1.5 feet tall. It was about as long as an average sport utility vehicle. The part was inarguably an impressive accomplishment – but that long length cannot compare to what Made In Space just 3D printed.

Made In Space is known for some pretty impressive accomplishments already. The company was responsible for the first 3D printer to be launched into space, and has since created a full Additive Manufacturing Facility (AMF) on the International Space station. Plenty of “firsts” have been set by the AMF as 3D printed tools, medical supplies, art and more have been 3D printed in space, the first of their kind. Now Made In Space has claimed the Guinness World Record for longest non-assembled 3D printed object, and it’s a lot longer than an SUV – it’s 37.7 meters, or 123 feet, 8.5 inches long.

That also happens to be the length of Made In Space’s Moffett Field facility at NASA’s Ames Research Center. The beam is now hanging from the ceiling of the facility. It was 3D printed with the company’s Extended Structure Additive Manufacturing Machine (ESAMM), which is the internal 3D printer of the Archinaut system. Archinaut uses robotic arms to assemble pre-fabricated and 3D printed components into larger, more complex structures, and will eventually be installed in space where it can autonomously repair things like satellites.

Trinity College Dublin (TCD), in Ireland, is to be the recipient of a new specialist 3D bioprinting facility supported by a collaboration between multinational medical device and pharmaceutical company Johnson & Johnson, and the AMBER research center.

With preparations beginning in the first quarter of this year, the new 3D bioprinting laboratory is due to be opened by the close of 2018.

Professor Michael Morris, AMBER director, comments.

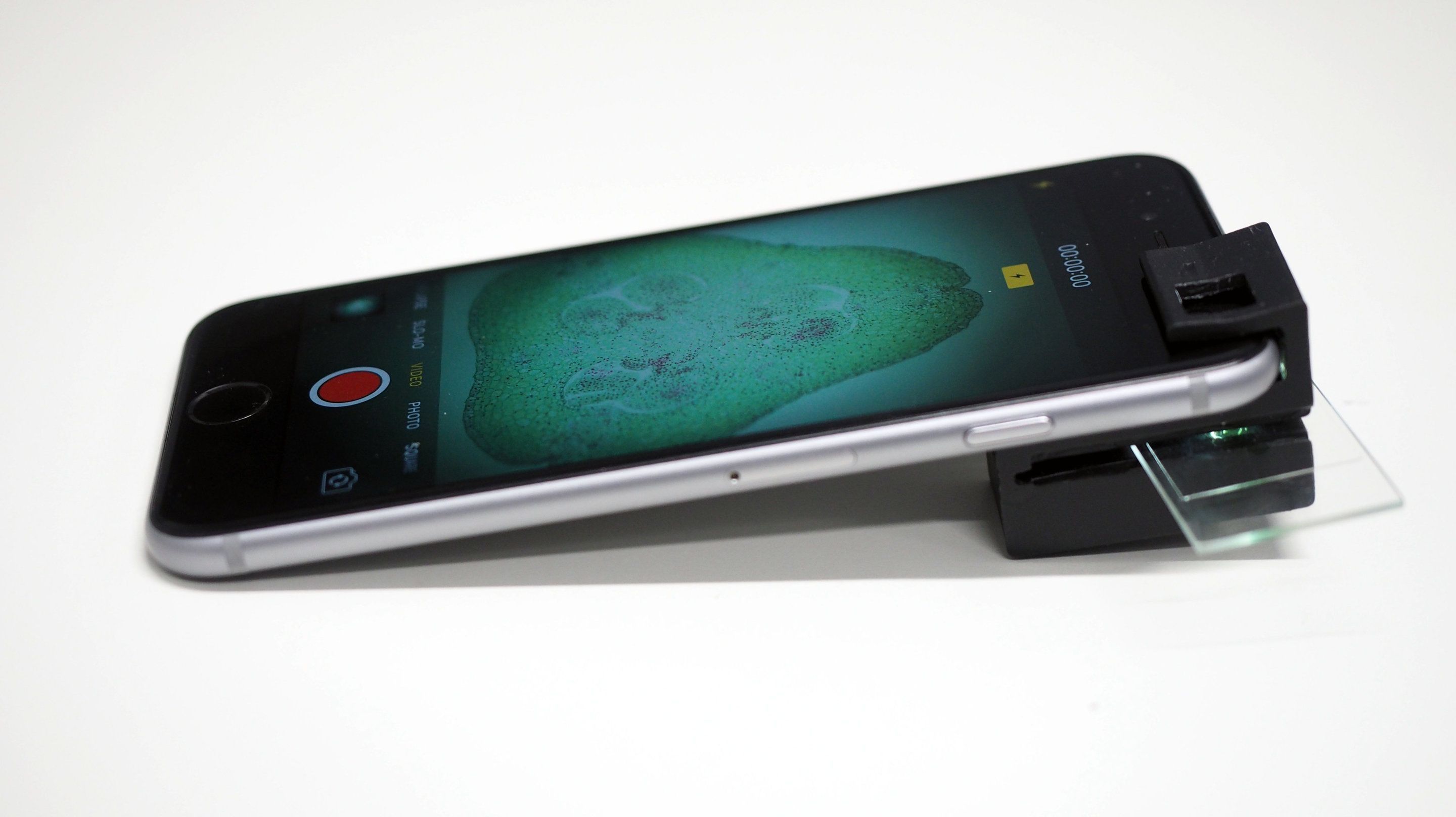

Australian researchers from the ARC Centre of Excellence for Nanoscale BioPhotonics (CNBP) have developed a 3D printable ‘clip-on’ that can turn any smartphone into a fully functional microscope.

Reported in the research journal Scientific Reports, the smartphone microscope is powerful enough to visualise specimens as small as 1/200th of a millimetre, including microscopic organisms, animal and plant cells, blood cells, cell nuclei and more.

The clip-on technology is unique in that it requires no external power or light source to work yet offers high-powered microscopic performance in a robust and mobile handheld package.