I gave the following speech at the Space Elevator Conference.

——

“Waste anything but time.”

—Motto of the NASA Apollo missions

The consensus amongst those of us who think it is even possible to build a space elevator is that it will take more than 20 years. But how can you say how long it will take to do something until you specify how many resources it will require and how many people you’ve assigned to the task?

For the first part of this speech, let’s pretend we can make the nanotubes and focus on the remaining 99%. When analyzing a task you generally know how to do, it is best to take a top-down approach. If you are painting a room, you would divide this task into the prep, the actual painting, and the cleanup, and then organize the work in each one of those phases.

In my former life at Microsoft, I learned to appreciate the power of educated and focused large-scale teams as the best tool to beat the competition. With a 1,000 person team, 1 man-year of work is accomplished every 2 hours. Work is generally fungible so a 20 year project could definitely use more people and go faster.

The goal in a project is for everyone to always be moving ahead full speed and to finish on the same day. What slips schedules is when you have people with dependencies on each other. If one person needs something from another to do their work, you have the potential for that person to go idle and to slip the entire project.

You can prevent that from happening with strong leadership. In the recent BP oil spill, Louisiana tried to get permission to build berms, but the EPA and the other agencies took a long time to analyze the environmental impact. The federal bureaucracy with all of its technology moved slower than lifeless oil floating in the ocean. A good leader can cut through red tape and bring in outside assets to unblock a situation.

The various big pieces of the space elevator have clear boundaries. Those building the solar panels need work with the climber team only to come up with a way to attach the panels. The physical shape of the climber impacts little on the anchor station. The primary issues are the throughput of tons per day and the process to load a climber. Even mission control looks at pieces as black boxes. Mega-projects can be broken down into efforts with clear boundaries so this means that in general, once commenced, everyone should be able to work in parallel.

The robotic climber is one of the most complicated pieces of hardware that the space elevator needs, and it has many of the same requirements as one of Seattle’s Boeing airplanes: both will move a few hundred miles per hour, and have to deal with difficult changes in temperature, pressure, and radiation.

Boeing is at least on a 7 year timeframe with its 787, compared to NASA which seems to takes decades to do anything. The goal is to be the quality of NASA, but faster than the speed of Boeing. Engineering is about humans and their computers, and both can be improved.

At least some of the 787’s delays were not technically related, as the local papers documented months of labor disputes. Boeing is also working more closely with its suppliers over the Internet than ever before, and learning how to do this.

Man landed on the moon 7 years after Kennedy’s speech, exactly as he ordained, because dates can be self-fulfilling prophecies. It allows everyone to measure their work against their plan and determine if they need additional resources. If you give out a few years of work per person, and allow for time for ramp-up and test, then about 7 years is quite reasonable. Long timelines encourage procrastination. If you want something to happen more slowly, you can find always ways to succeed.

It is cheaper to get loans for shorter terms, so it is cheaper to build something in 7 years than in 20. A 20-year plan is almost a guaranteed way to get a “no” answer. Even the U.S. Congress doesn’t think more than a few months ahead.

Boeing has the requisite technical skills, and they have 160,000 employees, so we could use them as a baseline of an estimate on how many people it would take. Here is what those 160,000 people work on:

|

Boeing Projects

|

|

2018 Bomber

737 Airborne Early Warning and Control (AEW&C)

737 AEW&C Peace Eagle

737 AEW&C Wedgetail

767 Airborne Warning and Control System (AWACS)

A-10 Thunderbolt II

A160 Hummingbird

AC-130U Gunship

Aegis SM-3

Airborne Early Warning and Control

AGM 86-C Conventional Air-Launched Cruise Missile (CALCM)

AH-64 Apache

AV-8B Harrier II Plus

Airborne Battle Management (ABM)

Airborne Warning and Control System (AWACS)

Airlift and Tankers (A&T)

Advanced Global Services & Support

Advanced Tanker

Air Force One

Airborne Battle Management (ABM)

Airborne Laser Test Bed (ALTB)

Ares I Crew Launch Vehicle

Arrow Interceptor

Avenger

B-1B Lancer

B-2 Spirit

B-52 Stratofortress

BattleScape

Boeing 376 Fleet

Boeing 601 Fleet

Boeing 702 Fleet

Boeing 702MP Spacecraft

Boeing Australia

Boeing Launch Services

Boeing Military Aircraft

Boeing Satellites

Brigade Combat Team Modernization (BCTM)

Brimstone Precision Guided Missile

C-17 Globemaster III

C-130 Avionics Modernization Program

C-32A Executive Transport

C-40A Clipper Military Transport

C-40B Special-Mission Aircraft

C-40C Operational Support and Team Travel Aircraft

Canard Rotor/Wing

CH-46E Sea Knight

CH-47D/F Chinook

Cargo Mission Contract (CMC)

Checkout, Assembly & Payload Processing Services (CAPPS)

Combat Survivor Evader Locator (CSEL)

Commercial/Civil Satellite Programs

Constellation/Ares I Crew Launch Vehicle

Conventional Air-Launched Cruise Missile (CALCM)

Cyber and Information Solutions

DataMaster

Defense & Government Services

Delta II

Delta IV

Directed Energy Systems (DES)

DIRECTV 1, 2, 3

DIRECTV 10, 11, 12

DRT

|

E-3 AWACS

E-4B Advanced Airborne Command Post

E-6 Tacamo

EA-18G Airborne Electronic Attack Aircraft

Engineering & Logistics Services

F-15E Strike Eagle

F-15K — Republic of Korea

F/A-18 Hornet

F/A-18E/F Super Hornet

F-22 Raptor

F/A-18E/F Integrated Readiness Support Teaming (FIRST)

Family of Advanced Beyond Line-of-Sight Terminals (FAB-T)

Global Broadcast Service (GBS)

Global Services & Support

Global Positioning System

Global Positioning System (GPS) IIF

Global Security Systems

GSA

GOES N-P

Ground-based Midcourse Defense (GMD) System

Harpoon

Harrier

Hornet

I&SS Mission Systems

Insitu

Integrated Logistics

Integrated Weapons System Support Program

Intelligence and Security Systems

Intelsat

International Space Station (ISS)

Iridium

Intelligence, Surveillance, Reconnaissance (ISR) Services

Joint Direct Attack Munition (JDAM)

Joint Effects-Based Command and Control (JEBC2)

Joint Helmet-Mounted Cueing System (JHMCS)

Joint Recovery and Distribution System (JRaDS)

Joint Tactical Radio System Ground Mobile Radios (JTRS GMR)

KC-10 Extender

KC-135 Stratotanker

KC-767 Advanced Tanker

Lancer

Laser & Electro-Optical Systems (LEOS)

Laser Joint Direct Attack Munition (LJDAM)

Leasat

MH-47E/G Special Operations Chinook

Maintenance, Modifications & Upgrades

Measat-3

Military Satellite Systems

Milstar II

Mission Operations

Mission Systems

|

Military Satellite Systems

Network and Space Systems

Network and Tactical Systems

Network Centric Operations

NSS-8

Orbital Express

P-8

Patriot Advanced Capability-3 (PAC-3)

Peace Eagle

Phantom Works

Raptor

Rotorcraft Systems

SQS

ScanEagle

Sea Knight

Sea Launch

SBInet

SkyTerra

Small Diameter Bomb (SDB)

SoftPlotter

SOSCOE

Space and Intelligence Systems

Space Based Space Surveillance (SBSS) System

Space Exploration

Space Flight Awareness

Space Shuttle

SPACEWAY 1, 2 North

Special Operations Chinook

Spectrolab

Spirit

St. Louis Flight Operations

Standoff Land Attack Missile Expanded Response SLAM ER

Strategic Missile & Defense Systems

Strategic Missile Systems

Stratofortress

Super Hornet

Supply Chain Services

T-45 Training System

Tacamo

TACSAT I

Tanker

Thuraya-2, 3

Training Support Center

Training Systems and Services

Transformational Wideband Communication Capabilities for the Warfighter

UH-46D Sea Knight

UHF Follow-On

Unmanned Airborne Systems

Unmanned Little Bird

V-22 Osprey

VSOC Sentinel

Wedgetail

Wideband Global SATCOM (WGS)

X-37B Orbital Test Vehicle

X-51 WaveRider

XM Satellite Radio

XM-3, 4

XSS Micro-Satellite

|

The news in Seattle was how Boeing’s 787 was continually being delayed, but they are involved in so many military and space efforts, it is surprising they find any time at all to work on their Dreamliner!

Boeing is working on 150 projects, so they have 1,100 people per project. Averages are more prone to error, so we can assume a space elevator is 10 times bigger than average. This gives you 11,000 people. If you knew the size of the teams at Boeing, something which is not public information, you could better refine the estimates. A 11,000 person team would be a sight to behold.

If we landed on the moon 7 years after Kennedy told us we would, and if Boeing can build the 787 in 7 years, they we can build the rest of the space elevator in 7 years. It is just a matter of having enough of the right people. So 11,000 people in about 7 years is a first estimate. But this is the 21st century, and we landed on the moon 40 years ago.

Software

Software is my training, and what I will turn to now. Ford Motor Company made an ad that said before they build a car, they build it inside a computer. If you are satisfied with the design inside a computer, you are ready to start production. What is true for a car is even more true for an airplane, and there is a lot of software involved in designing, testing, running and maintaining an airplane, and I’ve had the chance to talk to some Boeing engineers in my years in Seattle. It would not be surprising if the majority of engineers at Boeing knew how to program, and that software is a large part of Boeing’s investments. On the Wikipedia page for the 787, their (proprietary) software is mentioned several times as being a reason for delays.

Setting aside the space elevator, the key to faster technological progress is the more widespread use of free software in all aspects of science. For example, I believe there are more than enough computer vision PhDs, but there are 200+ different codebases and countless proprietary ones. Simply put, there is no computer vision codebase with critical mass, and this problem exists for a number of problem domains. The lessons of Wikipedia have not been learned.

We are not lacking hardware. Computers today can do billions of additions per second. If you could do 32-bit addition in your head in one second, it would take you 30 years to do the billion that your computer can do in that second.

While a brain is different from a computer in that it does work in parallel, such parallelization only makes it happen faster, it does not change the result. Anything accomplished in our parallel brain could also be accomplished on computers of today, which can do only one thing at a time, but at the rate of billions per second. A 1-gigahertz processor can do 1,000 different operations on a million pieces of data in one second. With such speed, you don’t even need multiple processors. Even so, more parallelism is coming via GPUs.

I have written a book that has ideas on how to write better software faster. Today, too many programmers of this world have not adopted free software and modern programming languages. I cannot speak for the shortest amount of time it would take to build the hardware for the space elevator, but I can speak a little bit about the software. Software is interesting because it seems there is no limit on the number of people who can work together.

Linux’s first release in 1991 was built by one programmer and had 10,000 lines of code. It is now 1,000 times bigger and has 1,000 times as many people working on it. Software is something like Wikipedia, which started with a handful but now has millions of people who have made contributions. I grabbed a random article on Wikipedia: it was 5,000 words which is a decent hunk of intellectual property, about as long as this speech which is half-over. It had 1,500 revision and 923 contributors. Each person noticed something different; not every change is perfect, but newer changes can further polish the work, and it usually heads in the right direction evolving towards a good state. A corollary of the point is the line by Eric Raymond that with enough eyeballs, all bugs in software are shallow.

Leonardo Da Vinci said that: “Art is never finished, only abandoned.” This is true of software as well because both are perfectable to an arbitrary degree. Every software programmer has had a feeling in his gut that if he had more resources, he could do more things. Software is different than Wikipedia, but I have found generally that problems in software, assuming you have the right expertise, can be broken up into arbitrarily small tasks. Every interesting problem can be expressed as a functional interface and a graph of code that someone else can maintain.

Some think that the AI problems are so hard that it isn’t a matter of writing code, it is a matter of coming up with the breakthroughs on a chalkboard. But people can generally agree at a high level how the software for solving many problems will work and there has been code for all manner of interesting AI kicking around for decades.

What we never built, and still don’t have, are some places where lots of people have come together to hash out the details, which is a lot closer to Wikipedia than it first appears. Software advances in a steady, stepwise fashion, which is why we need free software licenses: to incorporate all the incremental advancements that each random scientist is making. Even if you believe we need more scientific breakthroughs, it should be clear that things like robust computer vision are complicated enough that you would want 100s of people working together on the vision pipeline. So, while we are waiting for those “breakthroughs, let’s just get the 100 people together.

A big part of the problem is that C and C++ have not been retired. These languages make it hard for programmers to work together, even if they wanted to. There are all sorts of inefficiencies of time, from learning the archane rules about these ungainly languages (especially C++), to the fact that libraries often use their own utility classes, synchronization primitives, error handling schemes, etc.

It is easier to write a specialized and custom computer vision library in C/C++ than to integrate OpenCV, the most popular free computer vision engine. OpenCV defines an entire world, down to the matrix class so it cannot just plug into whatever code you already have. It takes months to get familiar with everything. Most people just want to work. To facilitate cooperation, I recommend Python. Python is usable by PhDs and 8 year olds and it is a productive, free, reliable and rich language. Linux and Python are a big part of what we need. That gives a huge and growing baseline, but we have to choose to use it.

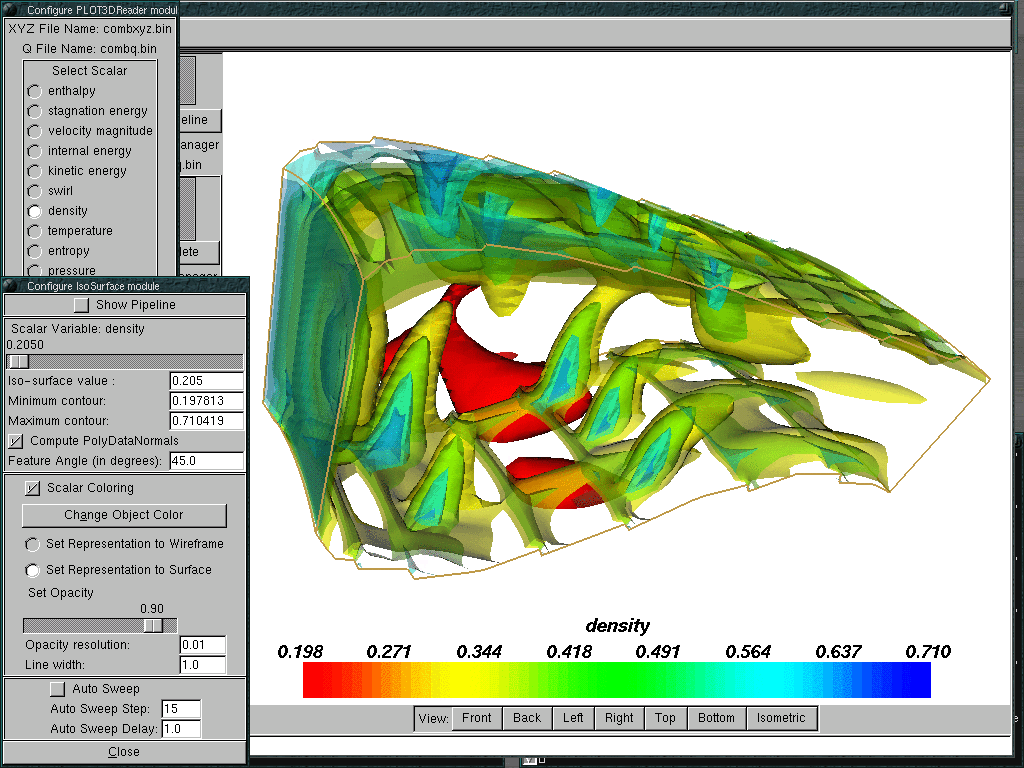

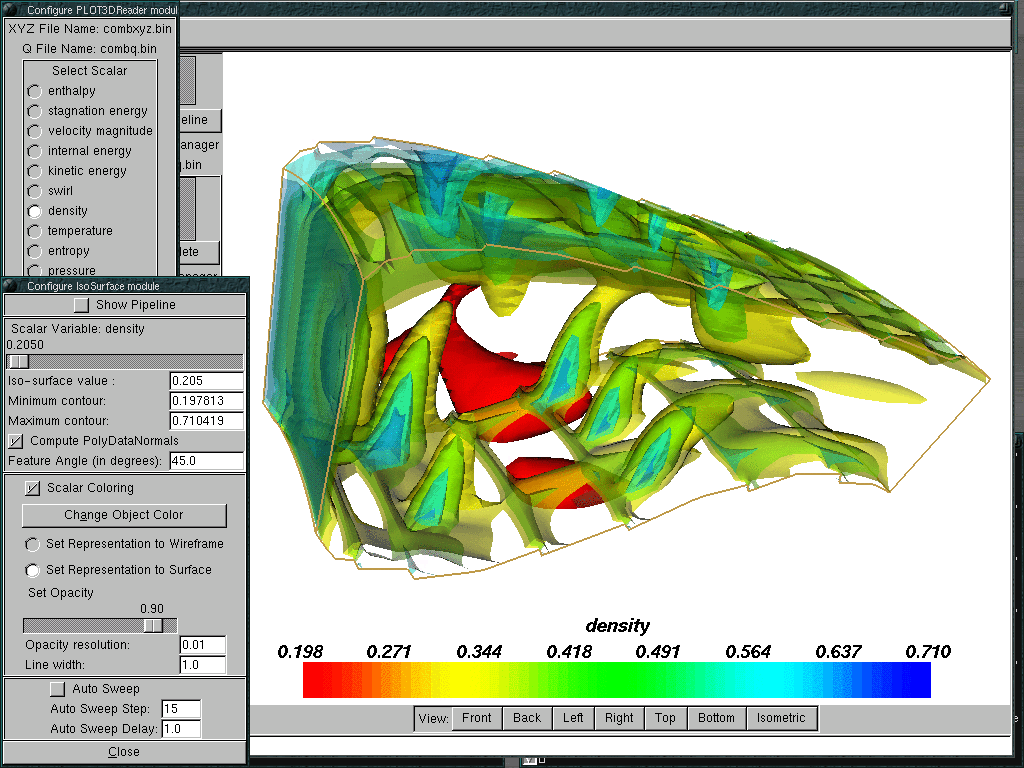

This is a screenshot of a fluid analysis of an internal combustion engine, and is built using a Python science library known as SciPy that can also do neural networks, and computer vision.

We might come up with a better language one day, but Python is good enough. The problem in software today is not a lack of hardware, or the technical challenge of writing code, it is the social challenge of making sure we are all working together productively. If we fix this, the future will arrive very fast. Another similarity between Wikipedia, free software, and the space elevator, is that all are cheaper than their alternatives.

So given all this technology at our disposal, we should be able to build this elevator in less than 7 years. Few would have predicted that it would take the unpaid volunteers of Wikipedia only 2.5 years to surpass Encyclopedia Britannica. Anything can happen in far less time than we think is possible if everyone steps up today to play their part. The way to be a part of the future is to invent it. We need to focus our scientific and creative energy towards big, shared goals. Wikipedia, as the world’s encyclopedia, is a useful and inspiring tool, and so people have come pouring in.

Future software advancements like cars that drive themselves will trigger a new perspective on whether we can build a space elevator. My backup plan to hitching a ride on the space elevator is to encourage people to build robot-driven cars first. Today, I’m trying the reverse approach.

The way to get help for a project is to create a vision that inspires others, but it would also be helpful if we got ten billion dollars. If the US can afford a $1.4 trillion dollar deficit, we can afford a space elevator.

There are already millions of people working in the free software movement today, so in a sense there already are millions of people working on the space elevator. If we had people with the right skills working, we could start writing the actual software for the space elevator. We could in principle write all of the software for the space elevator, just as Boeing and Ford do, which would further shrink the estimates.

Unfortunately, writing all the software now is theoretically possible but not practical. The problem is that a lot of what we need are device drivers. There are many ways to design the cargo door of the climber, and what the various steps of opening this door are. The software that controls the opening and closing of that door is a device driver, a state machine that coordinates all the littler pieces of hardware. You can even think of mission control as the software that orders all of the hardware pieces around. It is a meta-device-driver, so it can’t be written yet either. So, we are mostly stuck with our attempts to write too much software now, but there are a few things we can do.

We could use hardware designs. The hard part about us talking about a design aspect of a climber at a conference like this is that there is no canonical designs or team. Today, there is much interesting intellectual property locked up besides software.

Free data is also important however. Wikipedia has 2.6M lines of code to edit and display the encyclopedia, but it is gigabytes of data. Different projects have different ratios but software is useless without data. Everything Boeing does is proprietary today. We should fix that for the space elevator to encourage faster progress. If we all agree on free software and formats as baseline, it means people can work together. One big challenge is there is no free Solidworks replacement.

Even today, not everything that Boeing has locked up is innovative and strategic. They use standard military encryption algorithms which are public and free. Much of software is boring infrastructure code.

With free software and free formats, we can most quickly build the space elevator. So while it is bad news is that much of the required software efforts will be device drivers, the good news is that are some little software things we can work on today.

Dave Lang’s work on tethers is very useful, and it could use a team of people to work with him to port it from Fortran to Python. Dave started, but he didn’t know Python and the interop tools well enough to make progress. It would also be nice to get some people with supercomputers analyzing ribbon designs, and ways to bootstrap and repair a ribbon. NASA has people, but they don’t have this as their job.

I am hosting spaceelevatorwiki.com on my server and I plan on handing it over to ISEC, and it could serve as a place to coordinate various kinds of software or other R&D. If we could get some people to work, it would push others to get going. Nobody wants to be the only worker on a project. Even millions of dollars of money can be useful to jumpstart software efforts.

The 1% of the Carbon Nanotubes

Okay, so now on to the carbon nanotubes. This is not my area of expertise so it will be short. I am satisfied to make the case that a space elevator is 99% doable in less than 7 years and leave the resolution of the last 1% for another day. To adapt a line from Thomas Edison: success at building a space elevator is 99% perspiration and 1% inspiration.

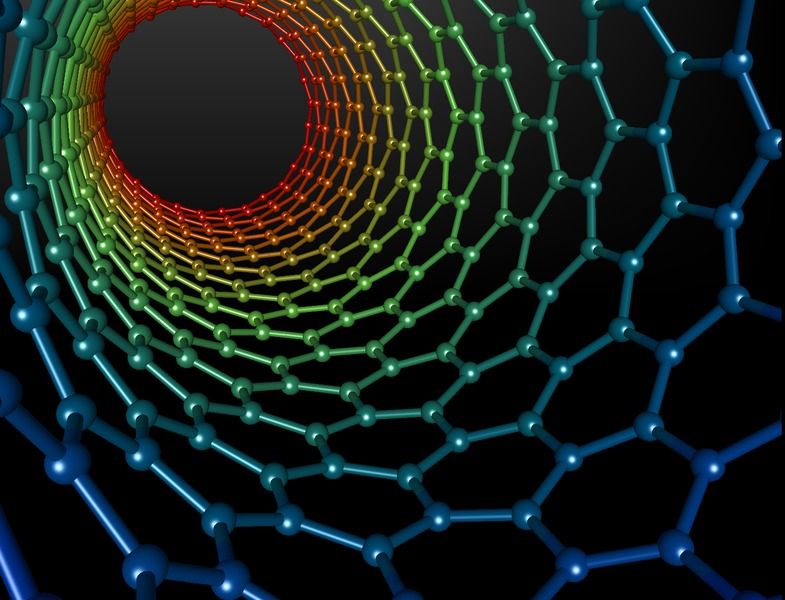

Many futurists believe that nanotechnology is the next big challenge after information technology. When analyzing a system you know how to build, it is best to work top-down. But when trying to do something new, you work your way up. When learning to cook, you start with an egg, not filet mignon. A good way to attack a big problem like nanotechnology is to first attack a small part of it, like carbon nanotubes. A Manhattan Project on general nanotechnology is too big and unfocused of a problem. Protein folding is by itself a Manhattan project!

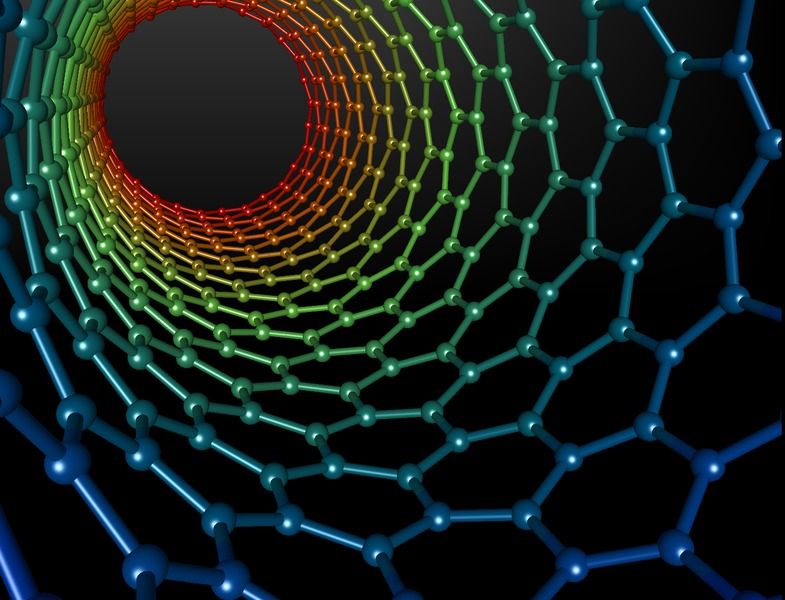

A carbon nanotube is a simple and useful nanoscale structure and could be a great way to launch atomically precise manufacturing. The ribbon needs some science related to the design of the ribbon, dealing with friction, damage, and decay, but that work can be done today on supercomputers. There are people at NASA that have the expertise and equipment, but they don’t have this as a goal. One of the points Kennedy made is that sending a man to the moon served as a goal to: “organize and measure.”

One concern is that there is a lot of money being spent on nanotube manufacturing research, but it is doled up in amounts of $100K. I am not convinced that such a small investment can bring any major new advancements.

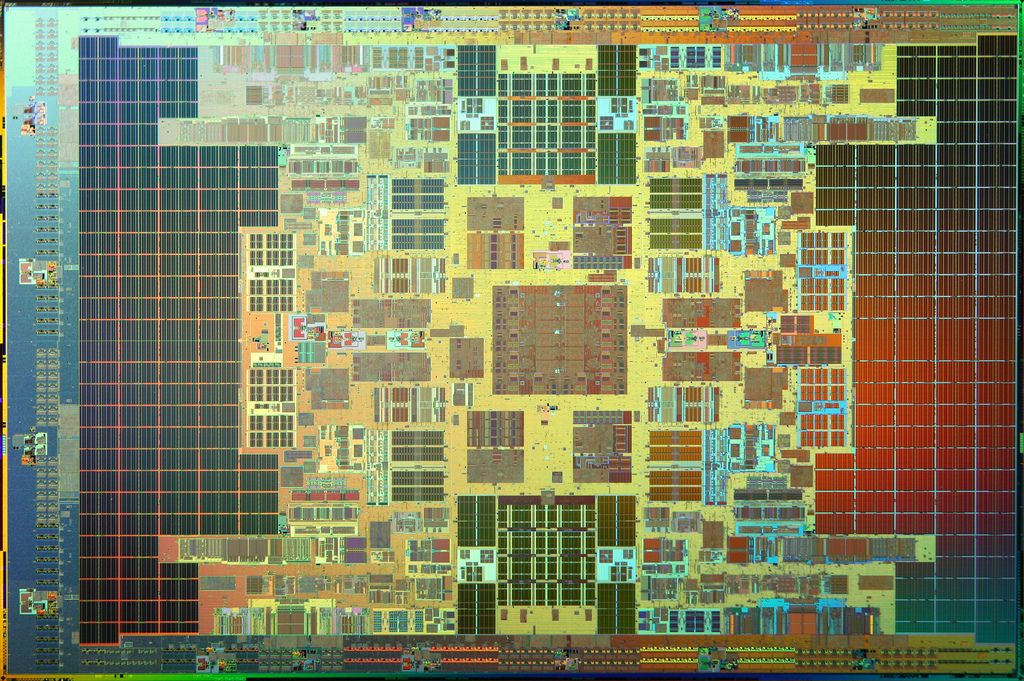

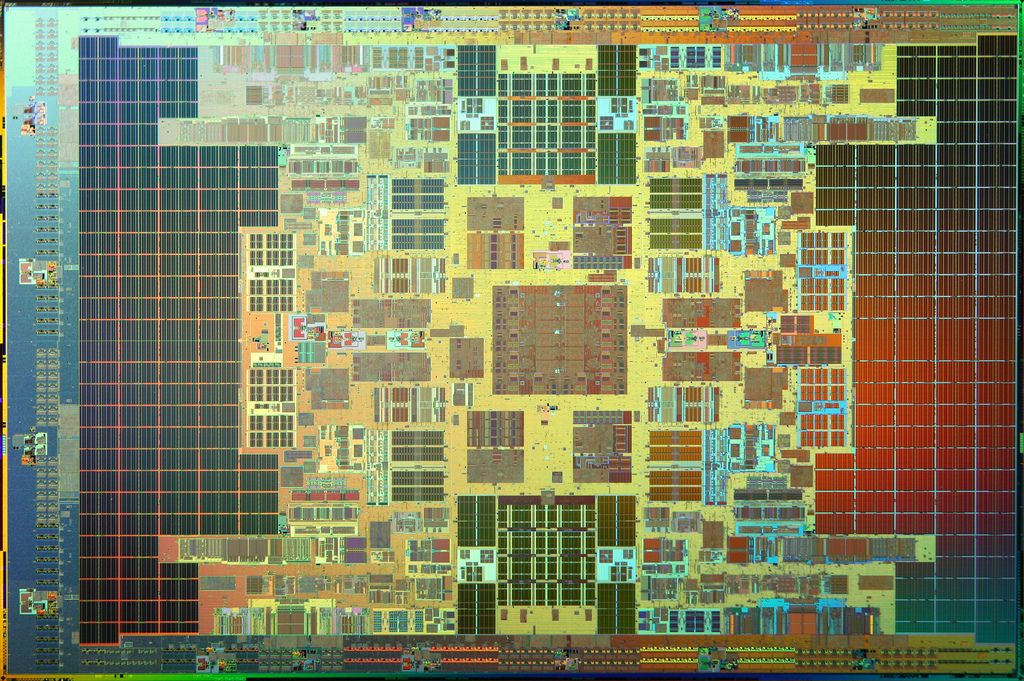

Nanotubes might require the existing industrial expertise of a company like Intel. We all know that NASA has not seriously considered building a space elevator, and similarly, I think that no one at Intel has considered the benefits to creating the world’s best nanotube threads. They already experimenting with nanotubes inside computer chips because metal loses the ability to conduct electricity at very small diameter, but they aren’t producing them as an independent product for purchase now.

Intel is working in the 35 nm scale today which is a long way from the 2nm nanotube scale. But Intel’s only goal today is faster and cheaper. Intel can fit 11 of their Atom processors on the surface area of a penny. Such a powerful processor is small enough for iPhone sized devices, let alone laptops which is their actual market.

Size is just a side-battle in their goals of more speed and lower production cost. So perhaps Intel would build a nanotube fabrication plant that looks nothing like what they are trying to do today:

Intel Itanium Processor

The first nanotube threads will likely not be good enough for the space elevator, but Intel learns how to build a better and smaller chip in the process of designing and building their current chip. So after they build this manufacturing plant, they could sell their product while they build their next one. Who knows how many of these iterations it would take, or ways to speed the progress up.

Brad Edwards tells me that with one-inch fibers, you can spin arbitrarily long carbon nanotube threads, using the textile process we’ve been following for centuries. Carbon nanotube are the simplest interesting nanoscale structure. Carbon nanotubes were discovered in 1991, and growing fibers in an oven and spinning them into threads is something we could have done back then. Companies like Hexcel, one of the world’s leaders in carbon fiber, is afraid to invest in carbon nanotubes even though they are the company in the world closest to being able to produce them. They are afraid of failure. I have discovered in software that it is about constantly adding new features which enable the new scenarios. Software is therefore constantly about generalizing. From where I sit, carbon fiber and carbon nanotubes are nearly the same thing! Even if it required new investments, Hexcel should be able to do it faster, better, and cheaper than anyone else, and they should have the most customers lined up who might want their new product. Hexcel, the company that should be leading in this market, is paralyzed into inaction by fear of failure. There is a moral obligation to innovation.

In conclusion, there is a new generation of kids maturing known as the Millennials. Their perspective is unique because they’ve been using Youtube and Google for as long as they can remember. They expect to get an answer to any question they pose in 100 milliseconds on their phone. The fact that Social Security is bankrupt is not acceptable. E=mc2 is sufficient proof that nuclear power is a good idea. If you tell them you’ve got a 20-year plan, they will reply that you don’t know what you are doing yet, and you need to develop better plans. Waiting 20 years for a space elevator once makes as much sense as waiting 30 minutes at the gas station. And they are right — they don’t need to change their perspective, the rest of us need to change ours.

I’m not a Millennial, I’m a Generation X’er, and we are the ones building it. But I’m a software person. It would require 10,000 of my first computer to have the same capacity as an iPhone. I see today’s hardware as magic, so I believe someone can conjure up high quality nanotube rope if they invested enough resources. It might not be good enough for the elevator, but it could be a revenue-generating business. In Kennedy’s Rice speech, he mentioned that the Apollo program needed “new metal alloys” that hadn’t been invented. He didn’t think it would be a problem back then and we shouldn’t be 100% convinced now either.

The International Space Station is a tin can in space. We can do a lot better. A space elevator is a railway to space. Scramjets, space tethers, rockets, or reusable launch vehicles, none of them are the way. Perhaps the Europeans could build the station at GEO. Russia could build the shuttle craft to move cargo between the space elevator and the moon. The Middle East could provide an electrical grid for the moon. China could take on the problem of cleaning up the orbital space debris and build the first moon base. Africa could design the means to terraform Mars, etc. This could all be done completely in parallel with the space elevator construction. We went to the moon 40 years ago, and the space elevator is our generation’s moon mission. Let’s do as Kennedy exhorted and: “Be bold”.

There are legal issues to consider. But when this project commences, we need to tell the bureaucrats to get out of the way. We should also approach the global warming crowd and tell them that even better than living in rice patties, and driving electric rickshaws, the best way to help comrade mother earth is with a space elevator. Colonizing space will changes man’s perspective. When we feel crammed onto this pale blue dot, we forget that any resource we could possibly want is out there in incomparably big numbers. This simple understanding is a prerequisite for a more optimistic and charitable society, which has characterized eras of great progress.

We have given this program a high national priority — even though I realize that this is in some measure an act of faith and vision, for we do not now know what benefits await us. But if I were to say, my fellow citizens, that we shall send to the moon, 240,000 miles away from the control station in Houston, a giant rocket more than 300 feet tall, the length of this football field, made of new metal alloys, some of which have not yet been invented, capable of standing heat and stresses several times more than have ever been experienced, fitted together with a precision better than the finest watch, carrying all the equipment needed for propulsion, guidance, control, communications, food and survival, on an untried mission, to an unknown celestial body, and then return it safely to earth, re-entering the atmosphere at speeds of over 25,000 miles per hour, causing heat about half that of the temperature of the sun …, and do all this, and do it right, and do it first before this decade is out — then we must be bold.

John F Kennedy, 1962