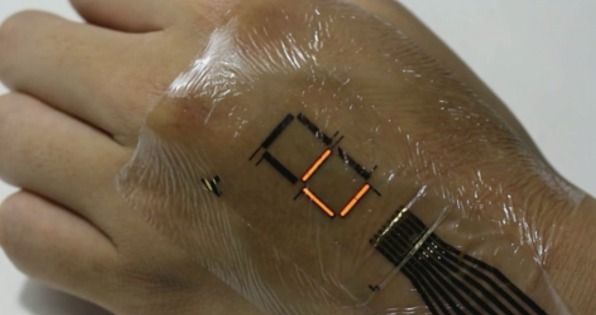

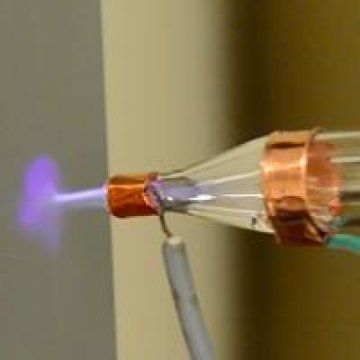

University of Tokyo researchers have created an ultrathin and ultraflexible organic e-skin that supports PLED and OLED displays.

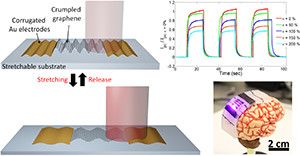

Researchers from the University of Tokyo have created a protective layer of organic material that’s ultrathin and ultraflexible. And the have demonstrated the material’s usefulness by making an OLED display that’s air-stable. This opens the possibility of developing better electronic skin displays, the next major leap in wearable technology.

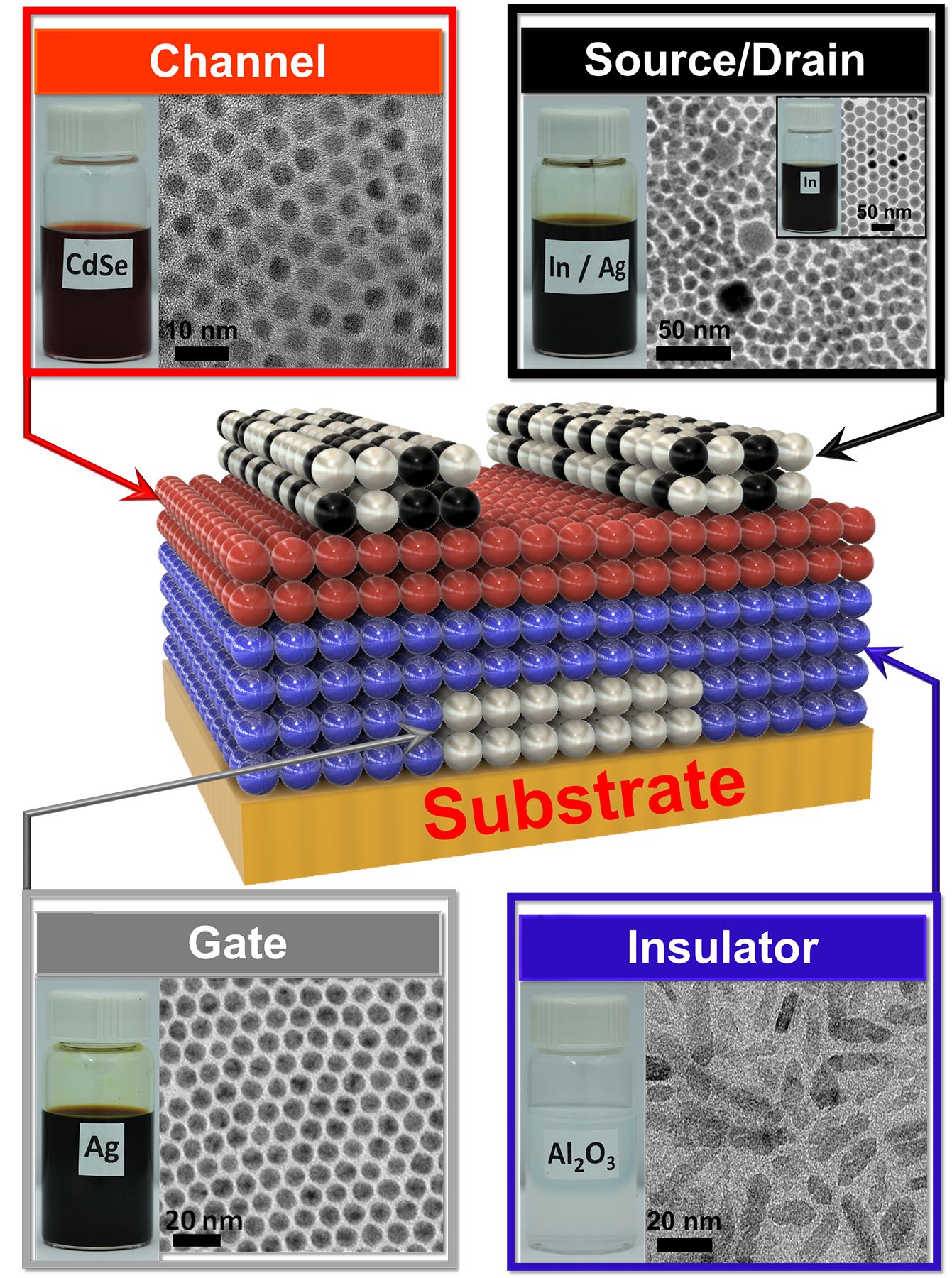

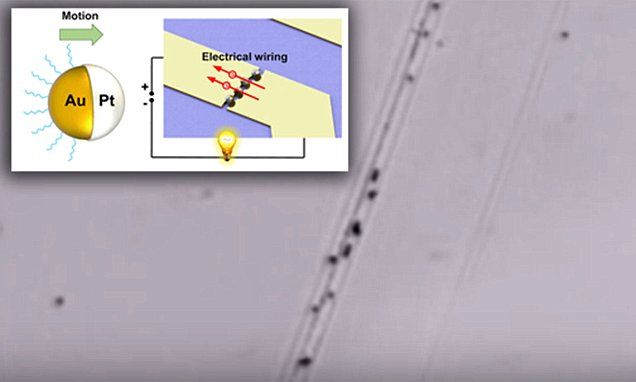

The thickness (or rather, thinness) and flexibility of wearable electronics is an essential factor in its further development. Plastic substrates are commonly used in the creation of such devices, which still require millimeter-scale thick glass. Also, whenever micrometer-scale and flexible organic materials are developed, they aren’t reliably stable when exposed to air.