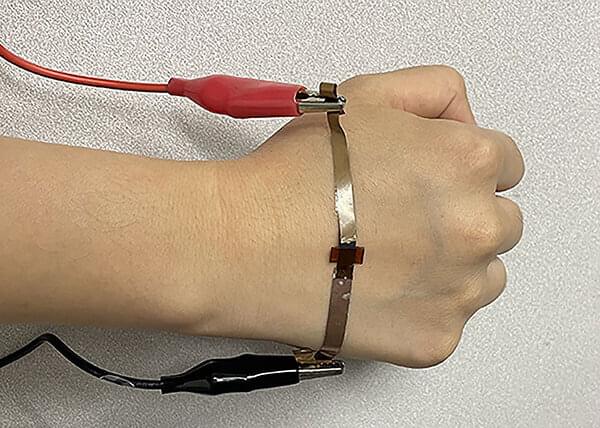

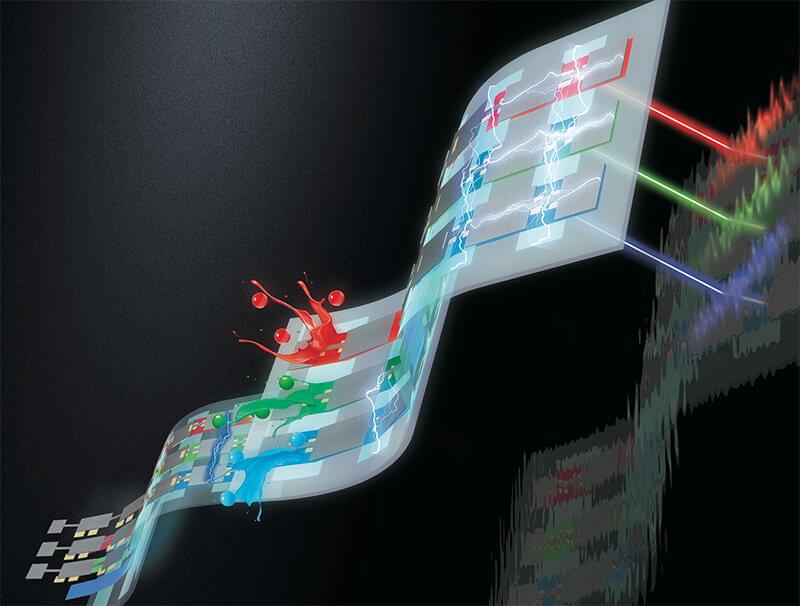

Know Labs’ glucose monitors are both powered by its Body-Radio Frequency Identification, or Bio-RFID, technology. The Bio-RFID sensors emit radio waves to measure specific molecular signatures in the blood through the skin, calculated using spectroscopy.

“We know that not all people with diabetes are looking for a wearable continuous glucose monitoring device to manage their diabetes. Some simply want to replace the painful, inconvenient and expensive fingersticks they currently rely on,” said CEO Phil Bosua, who invented the Bio-RFID technology. “The Bio-RFID sensor we currently use for our internal product testing fits in your pocket and is ready for final use, so we decided to create the KnowU as a portable, affordable and convenient alternative requiring no disposable items, such as test strips and lancets.”

In vitro tests have found that the radiofrequency sensor technology was able to measure glucose levels with accuracy comparable to that of Abbott’s Freestyle Libre continuous glucose monitor, which uses a sensor attached to the back of the arm for up to two weeks at a time. According to a 2018 study (PDF) comparing the two, 97% of the UBand’s readings were within 15% of the values calculated by Abbott’s device.