Clothing, skin patches and augmented reality glasses – welcome to the new age of data collection for mental health care.

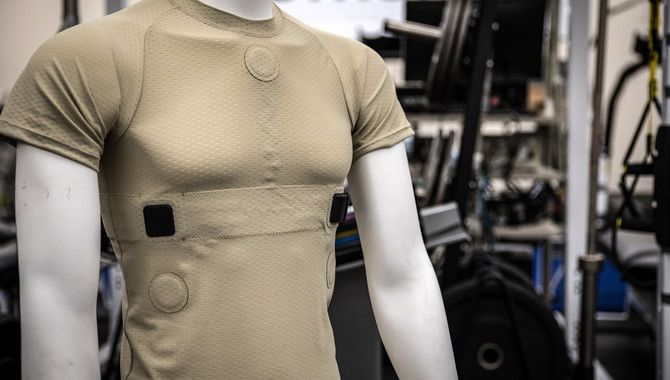

Wearable medical technology is designed to be small and lightweight to minimize additional burden on medical Airmen and the warfighter, whether they are on a remote battlefield or aboard an aircraft.

“Wearables provide greater accessibility,” said Dr. David Burch, a research biomedical engineer and the medical technology solutions team lead for the En Route Care Medical Technology Solutions Research Group, 711th HPW. “An aircraft has a very tight space and weight limit to maintain performance, and battlefield medics need to carry everything they use. Wearables provide accessibility to the human in a way that is better form, fit, and function.”

One wearable device that achieves that accessibility is a tissue oxygenation sensor, developed jointly with a private company. This small, soft, injectable sensor lets medics determine if a patient is able to be medically evacuated by assessing how well their blood transports oxygen to tissue.

Closing in on molecular manufacturing…

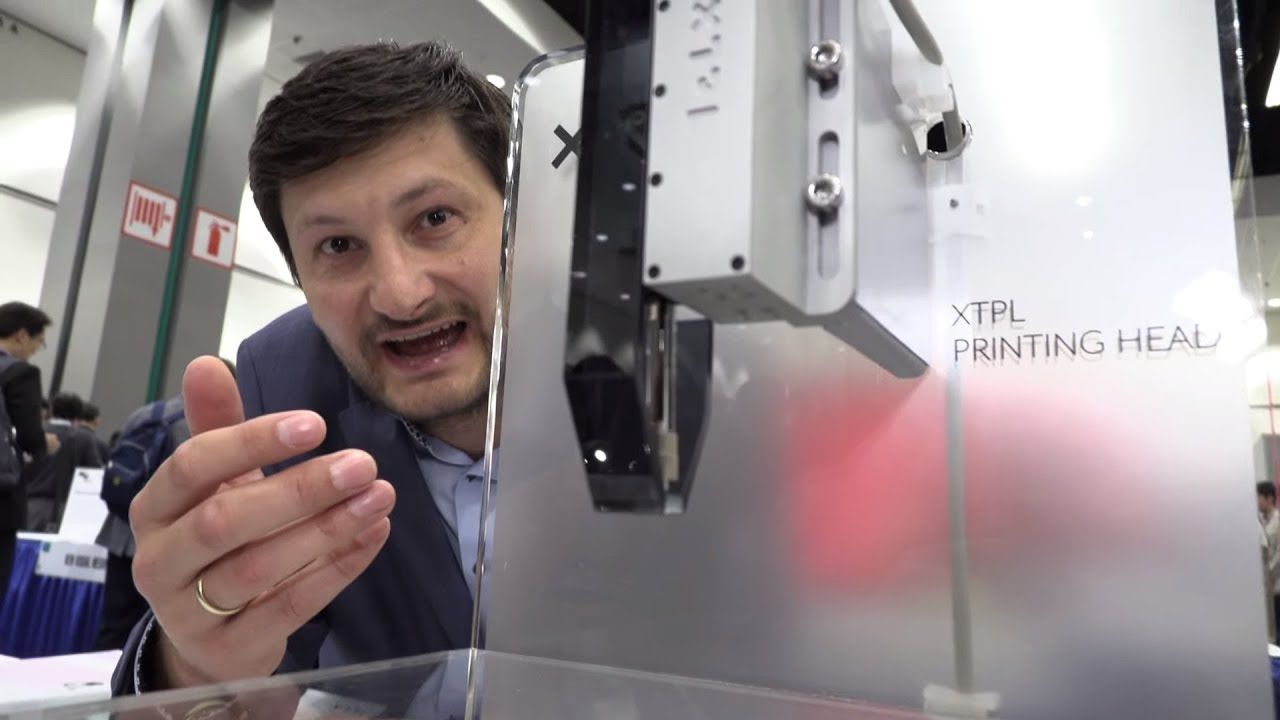

http://xt-pl.com received an honorable mention from I-Zone judges for its innovative product that prints extremely fine film structures using nanomaterials. XTPL’s interdisciplinary team is developing and commercializing an innovative technology that enables ultra-precise printing of electrodes up to several hundred times thinner than a human hair – conducive lines as thin as 100 nm. XTPL is facilitating the production of a new generation of transparent conductive films (TCFs) that are widely used in manufacturing. XTPL’s solution has a potentially disruptive technology in the production of displays, monitors, touchscreens, printed electronics, wearable electronics, smart packaging, automotive, medical devices, photovoltaic cells, biosensors, and anti-counterfeiting. The technology is also applicable to the open-defect repair industry (the repair of broken metallic connections in thin film electronic circuits) and offers cost-effective, non-toxic, flexible industry-adapted solutions.

XTPL’s technology might be the only one in the world offering cost-effective, non-toxic, flexible, industry adapted solution for the market of displays TFT/LCD/OLED, integrated circuits (IC), printed circuit boards (PCB), multichip modules (MCM); photolithographic masks & solar cells market.

XTPL delivers also solutions for research & prototyping including printing head, electronics, software algorithms which are the core of the system driving the electric field and the assembly process of nanoparticles implemented in XTPL’s Nanometric Lab Printer. It is a device that offers necessary functionalities to test, evaluate and use XTPL line-forming technology with nanometric precision and enables positioning of the printing head with micrometric resolution precisely.

Official video explaining XTPL’s technology: https://youtu.be/WMerzxzCXuw

Filmed at the I-Zone demo and prototype area at SID Display Week, the world’s largest and best exhibition for electronic information display technology.

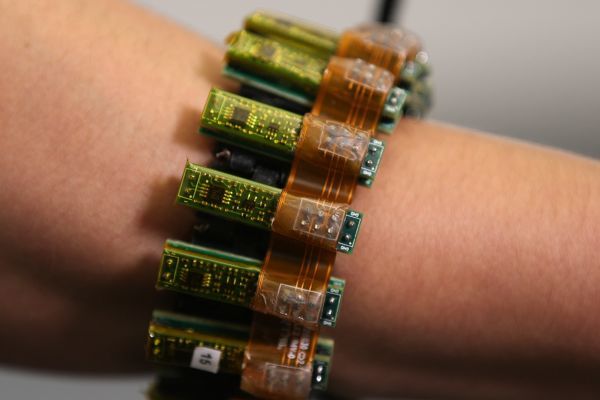

CTRL-labs’s noninvasive neural interface allows people to control computers, robots and applications by tracking electrical activity generated when a person thinks about moving. This electrical activity is detected by an armband outfitted with sensors and decoded by a computer. The team thinks the technology will initially be used for augmented and virtual reality, but CTRL-labs is already experimenting with medical applications.

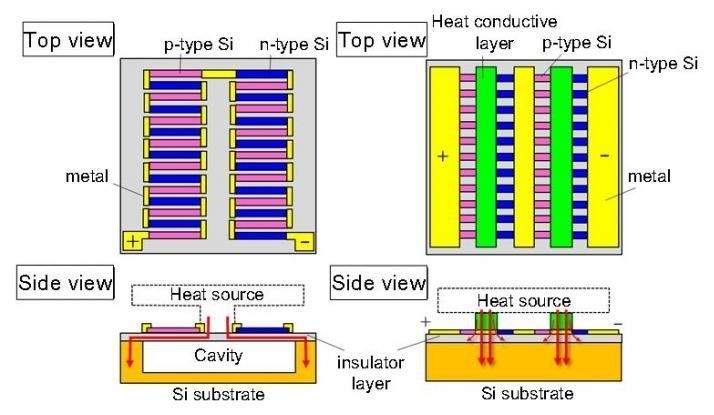

A team of Japanese researchers from Waseda University, Osaka University, and Shizuoka University designed and successfully developed a high-power, silicon-nanowire thermoelectric generator which, at a thermal difference of only 5 degrees C, could drive various IoT devices autonomously in the near future.

Objects in our daily lives, such as speakers, refrigerators, and even cars, are becoming “smarter” day by day as they connect to the internet and exchange data, creating the Internet of Things (IoT), a network among the objects themselves. Toward an IoT-based society, a miniaturized thermoelectric generator is anticipated to charge these objects, especially for those that are portable and wearable.

Due to advantages such as its relatively low thermal conductance but high electric conductance, silicon nanowires have emerged as a promising thermoelectric material. Silicon-based thermoelectric generators conventionally employed long, silicon nanowires of about 10–100 nanometers, which were suspended on a cavity to cutoff the bypass of the heat current and secure the temperature difference across the silicon nanowires. However, the cavity structure weakened the mechanical strength of the devices and increased the fabrication cost.

MyDefence is launching PITBULL – a next generation wearable Counter UAS solution utilizing smart jamming to defeat enemy drones. PITBULL is developed to have minimal impact on other signals while jamming, in an effort to maintain own communication. The Counter UAS jammer weighs 775 grams and can be worn on the uniform.

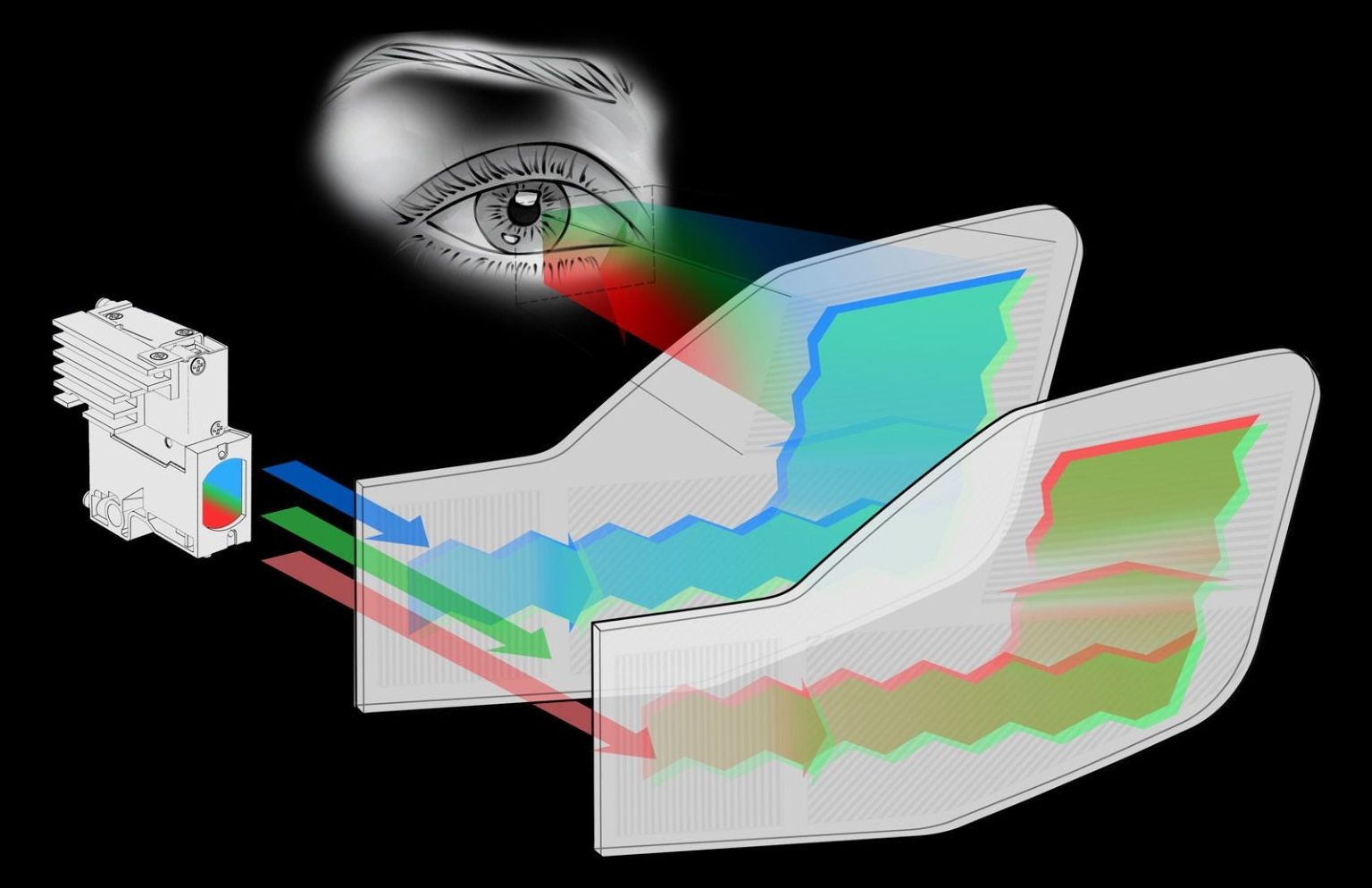

DigiLens, a developer of transparent waveguide display technology, says it’s working toward a waveguide display which could bring a 150 degree field of view to AR and VR (or XR) headsets. The company expects the display will be available in 2019.

Founded in 2005, DigiLens has developed a proprietary waveguide manufacturing process which allows the company to “print” light manipulating structures (Bragg gratings) into a thin and transparent material wherein light can be guided along the optic and be made to project perpendicularly, forming an image in the user’s eye. While DigiLens isn’t the only company which makes waveguide displays, they claim that their process offers a steep cost advantage compared to competitors. The company says they’ve raised $35 million between its Series A and B investment rounds.

While DigiLens’ displays have primarily been used in HUD-like applications, the company is increasingly positioning its wares toward the growing wearable, AR, and VR industries. At AWE 2018 last week, DigiLens Founder & CTO Jonathan Waldern told me that the company expects to offer a waveguide display suitable for AR and VR headsets which could offer a 150 degree field of view between both eyes. He said that a single display could be suitable for AR and VR modes in the same headset by utilizing a liquid crystal blackout layer which can switch between transparent and opaque, something which DigiLens partner Panasonic has developed. A clip-on light blocker or other type of tinting film ought to be suitable as well.