Nikola Motor Company designs and manufactures electric components, drivetrains and vehicles including the Nikola One and Nikola Two electric semi-trucks.

Tesla’s first Gigafactory in Reno, Nevada, has a well-documented place in the company’s history, both for how it helped Elon Musk ship his first mass-market electric car and because production problems there nearly doomed the automaker. But what’s been harder to come by is an account of the impact the factory has had on the town it was built for — until this week, that is. USA Today’s The City podcast spent an episode vividly retelling how Tesla’s first Gigafactory came to Reno with a deep dive into the way it’s changed the city.

Chinese carmaker unveils the ‘world’s cheapest electric car,’ starting at less than $9,000.

Twentieth Century technology has relied on the use of fuels and chemical propellants to propel our ships, planes, and cars. The propulsion technology of the future will not use chemical combustion to produce thrust, and the 21st century will see the emergence of propellant-less propulsion systems. Such technologies will provide the means to travel faster than ever before at a fraction of current costs and with no pollution by-products.

This becomes absolutely crucial for interplanetary and interstellar travel, as we have stated before in RSF commentary1 reporting on Resonance-based technology may provide inertial mass reduction—the future of space travel will not be performed with chemical propellants. As an example, to date the most viable proposal for an interstellar mission with current technological capabilities is the Breakthrough Starshot project which will use a fleet of light sail probes propelled to 20% percent the speed of light via laser pulses.

Considering the significant limitations of combustion-based propulsion (as well as the harmful environmental impacts), there is a strong drive to develop the next-generation propulsion systems that will move us into the next phase of technological advancement. Torus Tech, a research and development company founded by Nassim Haramein, the founder of the Resonance Science Foundation, is researching quantum vacuum engineering technologies that will enable gravitational control and zero-point energy production.

Anyone who’s owned a vintage car can tell you—and boy, will they tell you—how much time, money, and maintenance is required to keep their baby running. And don’t forget the gasoline, garage oil puddles, or tailpipe pollution involved.

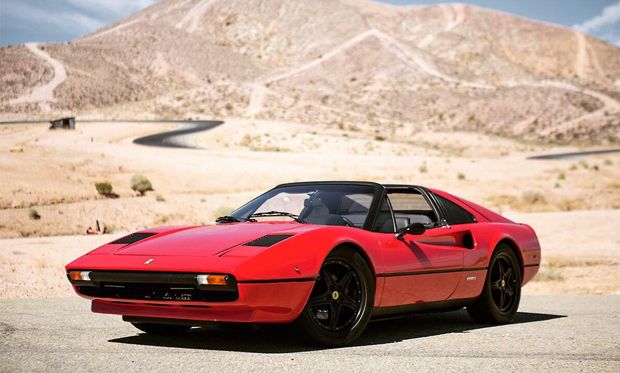

A California startup may have the answer: A plug-and-play innovative motor to convert that finicky old gas-guzzler into an electric car. Eric Hutchison and Brock Winberg first gained attention by rescuing a moldering, V-8-powered 1978 Ferrari 308—you may know it as the model that “Magnum: P.I.” drove on TV—and transforming it into an electric marvel. Now, the co-founders of Electric GT have developed a DIY, electric “crate motor” that will let traditional gearheads or EV fans do the same.

“A lot of guys go out for a weekend in a classic car that’s 40 or 50 years old, but they get a ride home with AAA; it ends up being a one-way trip,” Hutchison says. “Here, you’re taking out 95 percent of the maintenance, which is the biggest problem with classic cars. So this is for enthusiasts who love their cars, but want a fun, reliable car that’s good for 100 or 125 miles on a weekend drive.”

Circa 2017

Today, lithium is the active ingredient in batteries that power smart phones, laptops, and cars. But because of the price of lithium, researchers have been looking for another, more abundant element that could replace it. Several start-ups and established companies have tackled the idea of developing rechargeable batteries in which the active ingredient is sodium, lithium’s neighbor on the periodic table.

Besides its availability, sodium has several other important properties—not the least of which is its resistance to catching on fire. What’s more, “It was a good candidate because it could store a similar amount of energy as compared to lithium,” remembers Minah Lee, who does research on sodium batteries at Stanford University.

Today a number of companies are working on developing sodium batteries with the ultimate aim of replacing lithium as the key ingredient. The CNRS, The National Center for Scientific Research in France, recently announced the creation of Tiamat, a start-up company based in Amiens, France, that will develop and bring to the market a sodium rechargeable battery by 2020. CNRS says the battery will be designed in the widespread industrial 18650 format.

Say hello to the BlackBird: The car that can shift into any shape you want.

It can reportedly cover the 55 miles between San Jose and San Francisco in just 15 minutes.