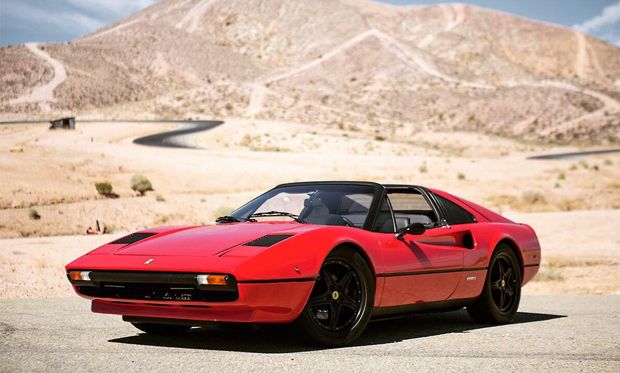

Nikola Motor, the Phoenix-based startup that wants to disrupt trucking with futuristic electric semis powered by hydrogen, says it has developed a new type of battery cell with double the energy density, only 40% of the weight and half the cost of current lithium-ion batteries used in Teslas and other consumer-market electric vehicles.

But it’s not providing many details for now, and public demonstrations won’t happen for about 10 months.

Battery packs using the new cells, which don’t use nickel, cobalt and other metals typically found in 2170 lithium-ion cells favored by Tesla, could boost range for current electric passenger cars from 300 miles per charge to as much as 600 miles with “little or no increase to battery size and weight,” the company said. Nikola has subjected its cells to heavy-duty testing and says that charging and depleting them “over 2,000 times has shown acceptable end-of-life performance.”