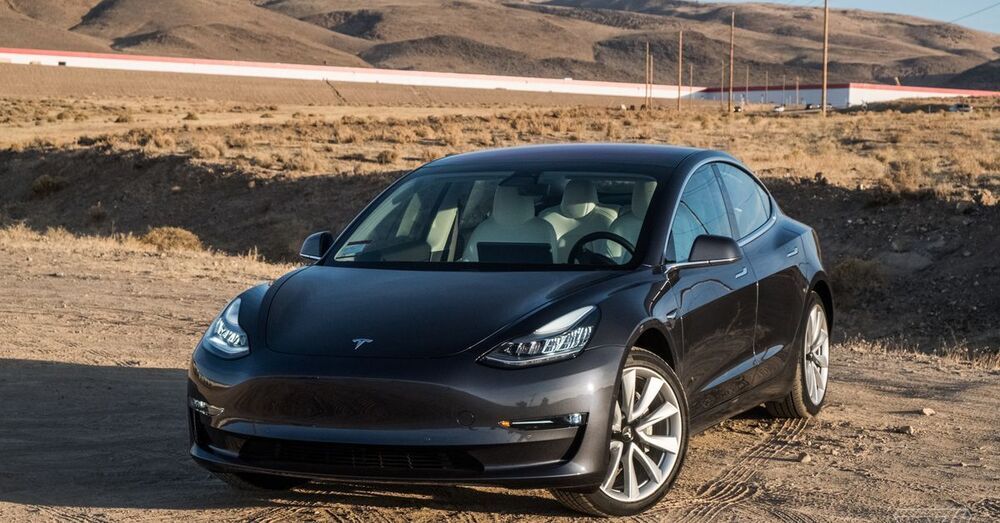

There are advantages to having a vehicle with instant acceleration. Stop lights become more fun, and occasionally, it’s equally to surprise some high-performance gas cars with a sudden sprint. At times, though, this instant acceleration becomes a safety feature, as recently proven by Tesla owner Daniel Spalding, who avoided a potentially nasty crash by a hair’s breadth thanks to his Model 3’s torque.

Spalding, who has been documenting his ownership experience in his YouTube channel, recently shared a rather tense video that he recorded recently. The video was brief, but it featured something that no driver ever wants to see from the rear — a fast-approaching car that’s not decelerating enough. Usually, incidents like this end up with both cars being damaged significantly. Some drivers and passengers may even get injured.

Fortunately for Spalding, his Model 3 can access its full power when he floors the accelerator. In his video’s description, the Model 3 owner noted that traffic in front of him came to a sudden stop, and as it turned out, the car behind him — what appeared to be an Acura Integra — was clearly not paying attention. When he realized that the car behind him was about to hit him, Spalding floored his Model 3’s accelerator.