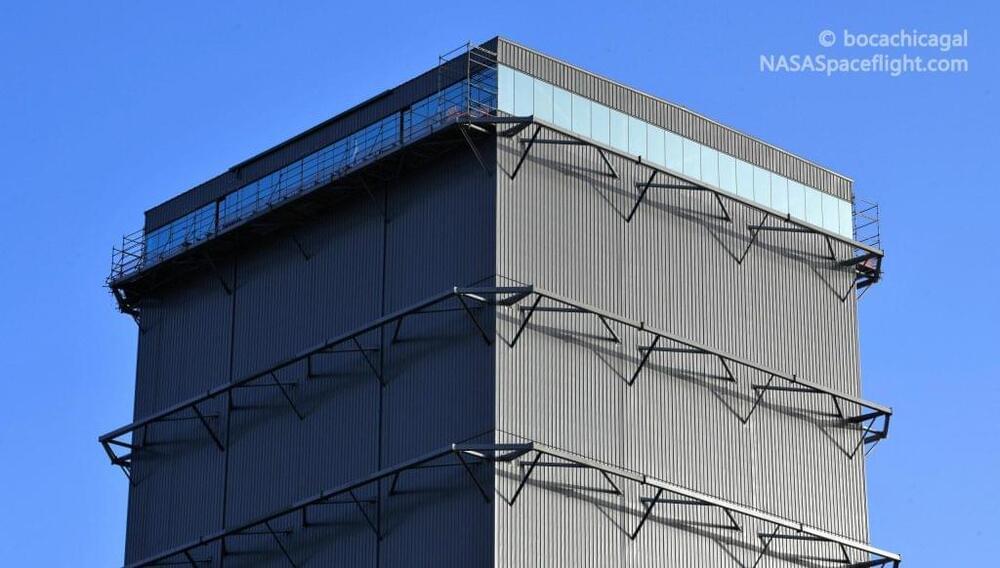

At ~5:02 pm CDT on August 27 2019, SpaceX successfully launched its Starhopper test vehicle on a 150-meter flight test. After ascending to 150-meters, Starhopper successfully landed at a landing pad ~160-meters away.

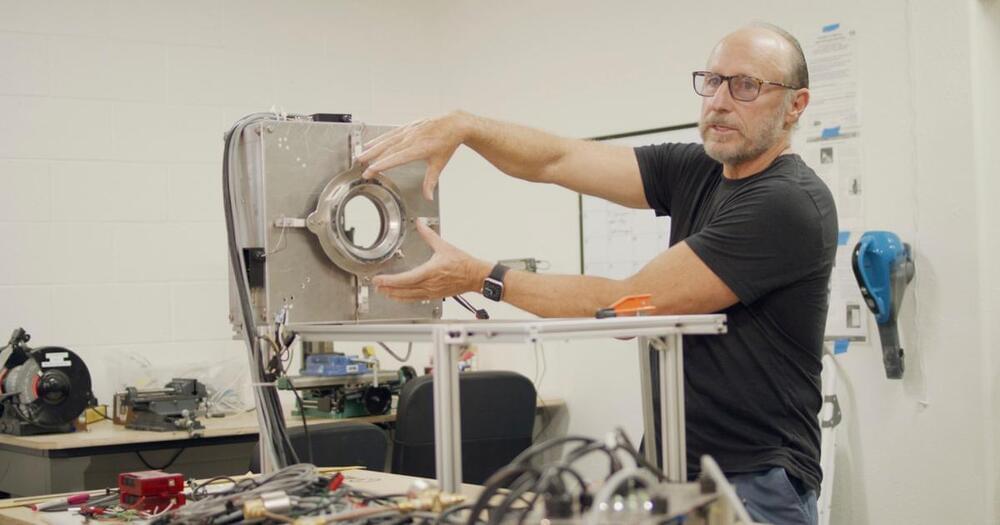

The 150-meter flight was the last of a long line of tests that Starhopper, the first vehicle in the Starship program, conducted. It was based on the Big Falcon Rocket (BFR, a previous name for Starship)2018design. Starhopper used a single Raptor engine and three non-retractable legs.

After several static fires, a one-meter tethered hop, and several scrubs, Starhopper conducted a 20-meter hop on July 25 2019. This was Starhopper’s first major flight and the first time a Raptor was used in flight.