Send your name to Mars and get your boarding pass!

SpaceX’s first 60 “production-design” Starlink satellites have been successfully placed in orbit, kicking off a constellation beta test at an unprecedented scale. According to CEO Elon Musk, all spacecraft also managed to successfully ‘phone home’ after separation.

The company’s Redmond satellite operators still need to verify that all spacecraft are functional and healthy after a Falcon 9 launch and chaotic deployment from the rocket’s upper stage, but the riskiest part of the mission is now arguably behind SpaceX. What remains is essentially a massive, hardware-rich test of SpaceX’s Starlink satellite constellation, ranging from granular flight testing of individual components to an effective simulation of a full constellation’s operations.

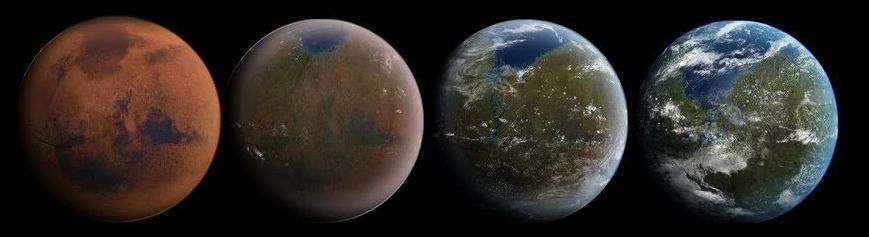

If you’ve ever yearned to travel to Mars, now is your chance. Well, okay, you can’t travel to Mars, but your name can, and that’s as close as you’re ever going to get.

The Mars 2020 Rover is getting ready to begin its seven-month trek to Mars next July, and NASA says it’ll take your name along with it:

But don’t linger in the interstellar vacuum, or hold your breath.

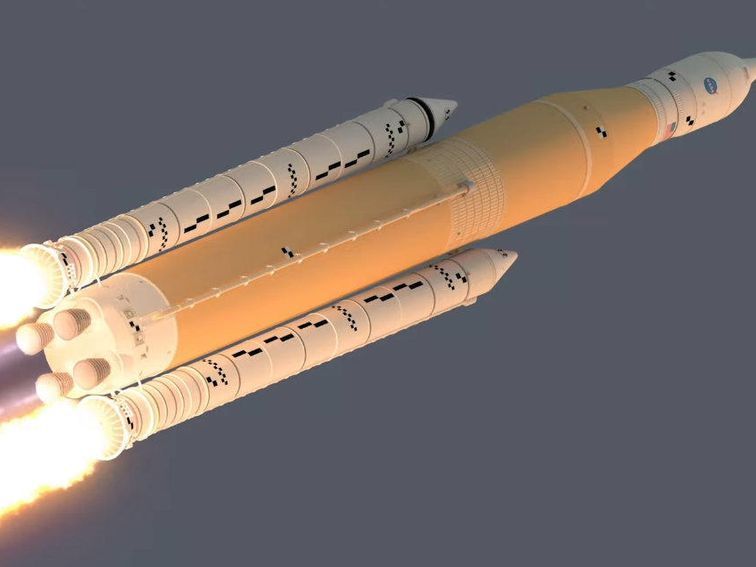

What would happen if energy, electricity, and power were pervasive and free? When a bum all the way up to an entire country would no longer have to worry about wars over oil, flights running out of fuel, or having to build a giant rocket to carry a giant tub of rocket fuel in order to get it to escape velocity and keep it going to Mars.

When you combine those two concepts: available anywhere at zero cost, you’ve got something more valuable than when man discovered fire.

Note that humankind didn’t invent fire. We discovered it. Because it already existed.

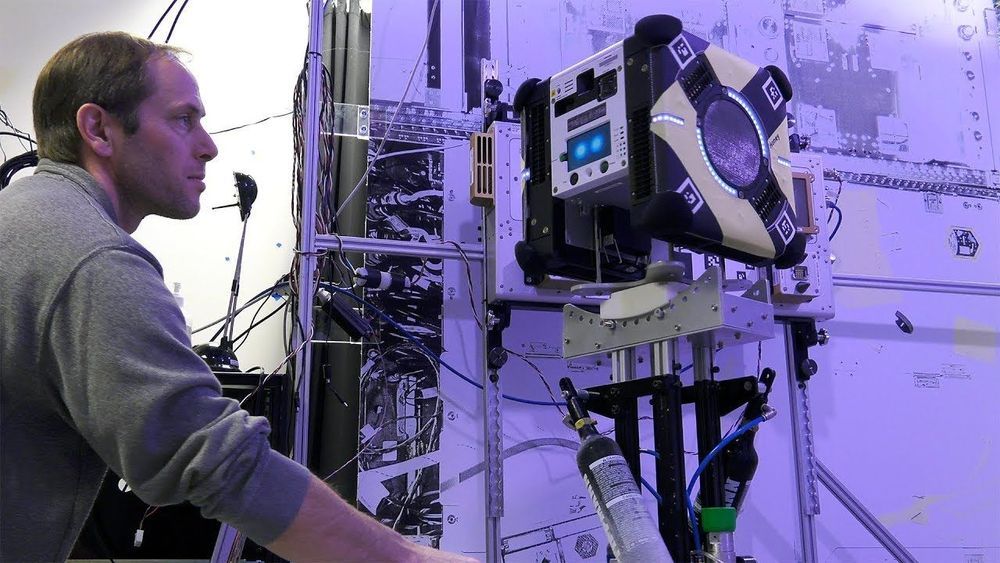

Robot bees are no replacement for our vital pollinators here on Earth. Up on the International Space Station, however, robots bearing the bee name could help spacefaring humans save precious time.

On Friday, NASA astronaut Anne McClain took one of the trio of Astrobees out for a spin. Bumble and its companion Honey both arrived on the ISS a month ago, and are currently going through a series of checks. Bumble passed the first hurdle when McClain manually flew it around the Japanese Experiment Module. Bumble took photos of the module which will be used to make a map for all the Astrobees, guiding them as they begin their tests there.

The three cube-shaped robots (Queen will arrive from Earth in the SpaceX resupply mission this July) don’t look anything like their namesakes, but they are non-threatening by design, says Astrobee project manager Maria Bualat. Since they’re built to fly around autonomously, doing tasks for the crew of the International Space Station, “one of our hardest problems is actually dealing with safety concerns,” she says.

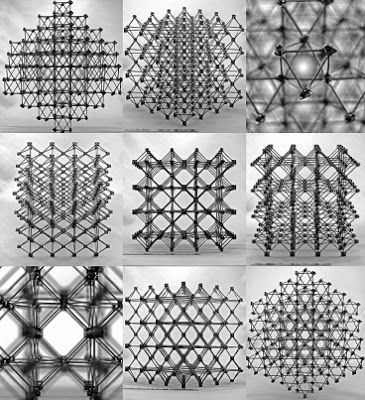

Researchers invent a new approach to assembling big structures — even airplanes and bridges — out of small interlocking composite components. MIT researchers have developed a lightweight structure whose tiny blocks can be snapped together much like the bricks of a child’s construction toy. The new material, the researchers say, could revolutionize the assembly of airplanes, spacecraft, and even larger structures, such as dikes and levees.

NBF – This is huge. It boosts what is possible with additive manufacturing and 3D printing. This will revolutionize manufacturing and construction.

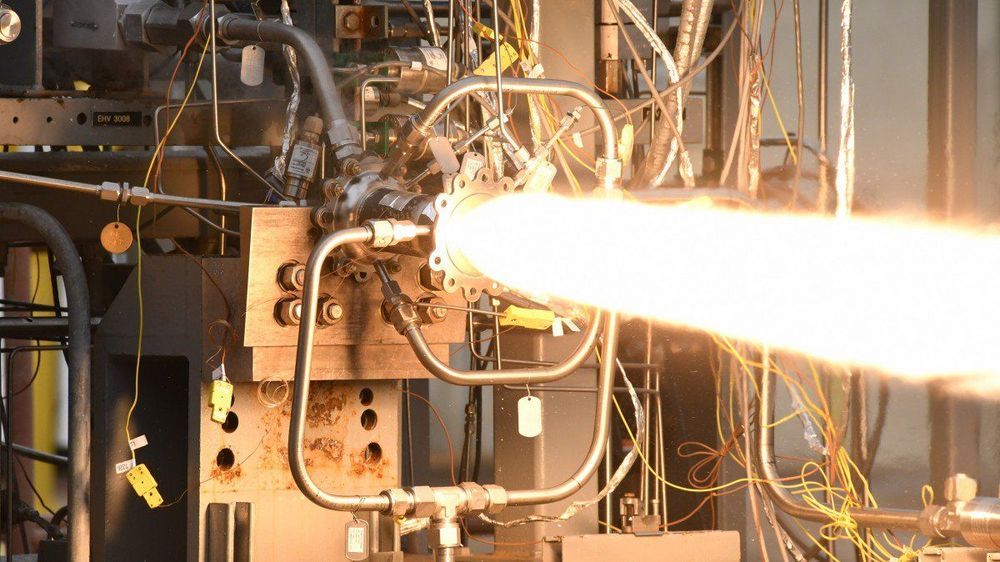

They have successfully test-fired 3D-printed combustion chambers made from multiple materials.

The news: By combining their manufacturing and testing capabilities, small-satellite launcher Virgin Orbit and NASA created a rocket combustion chamber that was 3D-printed from multiple metals. A combustion chamber is the container where all the propellants get mixed up and ignite—so it must be able to cope with extreme heat and force. The test part that used the chamber generated more than 2,000 pounds of thrust in a series of 60-second test fires. You can watch a video of the test firing here.

Why are chambers a challenge? Because it has to withstand so much, it must be designed to a very high standard, meaning the part is expensive and time consuming to make.