As Silicon Valley heralds progress on self-driving cars and robot carers, much of the rest of the country is worried about machines taking control of human tasks.

Category: robotics/AI

How much faster can you build a sneaker, exactly? A lot, it turns out. Wired UK has paid a visit to Adidas, which is hauling shoe manufacturing from labor-intensive Chinese plants into the aptly named Speed Factories in America and Germany.

Using tricks like robotic knitting, advanced plastic forming, and 3D printing (which is provided by Carbon, one of our 50 Smartest Companies of 2017) Adidas plans to make even custom sneakers 90 times faster than it can right now. It plans to crank out 1 million pairs of shoes a year from two Speed Factories—one in Atlanta, Georgia, the other in Bavaria, Germany—by the end of 2017.

Such innovation, it hopes, will allow it to remain competitive with Nike and Under Armor, which currently dominate the sportswear world.

The research community is beginning to understand that motivations are not a human “artifact” of consciousness, but part of the essential glue that binds consciousness together. Without motivations we have nothing that holds us to this vessel, ensuring that we continue to eat, pay our rent, and do other things necessary for our survival. Conscious machines will for this reason have motivations as well. Otherwise they simply just wouldn’t function. This is an important point because talk of the singularity often brings up visions of a single integrated “machine” that will inevitably enslave humanity. A better question is:

“Will AI be used to gain immense advantage for a single party (whether that party is the AI itself or the human that controls it), or will AI be used to maximize benefit for us all?”

Even if the AIs have interfaces that allow them to share information more rapidly than humans can through reading or watching media, separate AIs will have separate motivations from a single centralized AI. Given that a signature of consciousness is motivation, any consciousness will obviously be motivated to secure all the resources it needs to ensure its survival. In some cases, the most efficient way to secure resources is sharing. In other cases, it’s through competition. AIs might share resources, but they might also compete.

https://youtube.com/watch?v=Vi5RBv79oik

Yann LeCun is Director of AI Research at Facebook and Silver Professor at New York University, affiliated with the Courant Institute, the Center for Neural Science and the Center for Data Science, for which he served as founding director until 2014. He received an EE Diploma from ESIEE (Paris) in 1983, a PhD in Computer Science from Université Pierre et Marie Curie (Paris) in 1987.

After a postdoc at the University of Toronto, he joined AT&T Bell Laboratories. He became head of the Image Processing Research Department at AT&T Labs-Research in 1996, and joined NYU in 2003 after a short tenure at the NEC Research Institute. In late 2013, LeCun became Director of AI Research at Facebook, while remaining on the NYU Faculty part-time. He was visiting professor at Collège de France in 2016.

Battle Bots

Posted in robotics/AI | Leave a Comment on Battle Bots

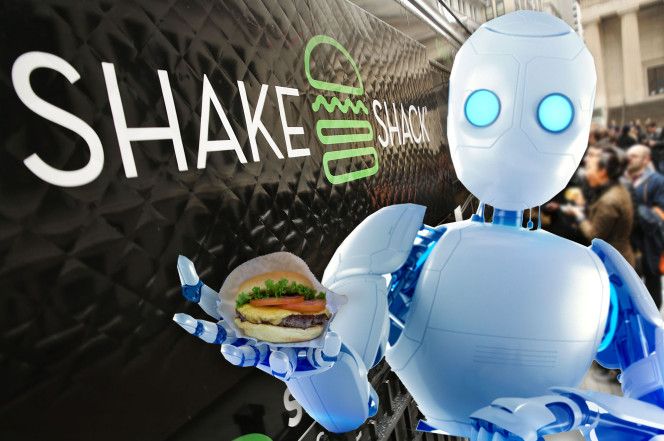

It’s the future of fast food bytes in the Big Apple.

Robots will replace humans and cash won’t be accepted at a soon-to-open Shake Shack in the East Village, reps for the popular burger chain said Monday.

Customers will place orders via an app and at touch-screen kiosks inside the restaurant, which is scheduled to open an Astor Place branch later this month, according to company CEO Randy Garutti.

The classic image of a robot is one clad in a rigid metal shell, but that might not be practical in situations where man and machine will need to work together. The emerging field of soft robotics is helping to make that collaboration safer, but recreating muscle is no easy task. Now, mechanical engineers from Columbia University have developed a synthetic soft muscle that’s said to be much more simple to make and run than others, and is three times stronger than the real thing.

Most soft robots are powered by pneumatic or hydraulic systems, with their movements controlled by filling and emptying bladders with liquids or gases. The problem is, that usually requires bulky external components like compressors, which prevent the systems from being shrunk down to practical sizes.

The system developed by the Columbia team is based on a natural muscle. It’s made of silicone rubber matrix pocked with micro-bubbles of ethanol, giving the material low density and high elasticity. It can be 3D printed into whatever shape is needed, then electrically actuated thanks to a thin resistive wire embedded inside. Altogether, it can be made easily, cheaply and safely.