A newly discovered papyrus contains an eye-witness account of the gathering of materials for the Great Pyramid.

The Team Seas event is live. For every $1 raised they will remove 1 pound of plastic from the ocean. Please support this event by watching supporting videos and material and donating.

Similar to grass stems, Lawrence Livermore National Laboratory (LLNL) scientists have created nanostrut-connected tube-in-tubes that enable stronger low-density structural materials.

Porous materials with engineered stretching-dominated lattice designs, which offer attractive mechanical properties with ultra-light weight and large surface area for wide-ranging applications, have recently achieved near-ideal linear scaling between stiffness and density.

In the new research, the team developed a process to transform fully dense, 3D-printed polymeric beams into graphitic carbon hollow tube-in-tube sandwich structures, where, similar to grass stems, the inner and outer tubes are connected through a network of struts. The research is on the cover of the Oct. 25 issue of Nature Materials.

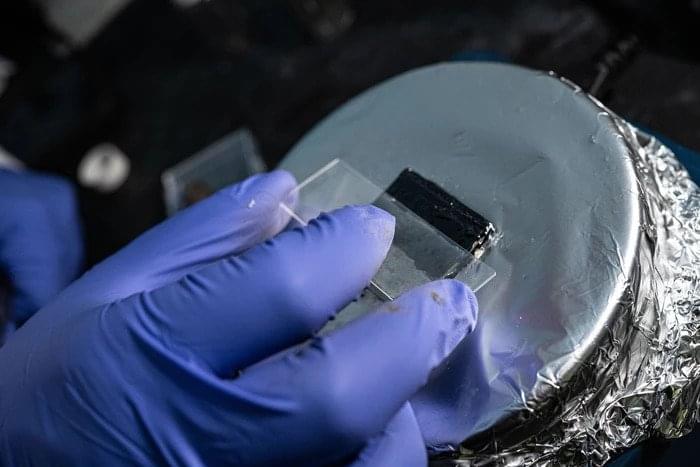

The sharpest knives available are made of either steel or ceramic, both of which are man-made materials that must be forged in furnaces under extreme temperatures. Now, researchers have developed a potentially more sustainable way to make sharp knives: using hardened wood. The method, presented October 20th, 2,021 in the journal Matter, makes wood 23 times harder, and a knife made from the material is nearly three times sharper than a stainless-steel dinner table knife.

“The knife cuts through a medium-well done steak easily, with similar performance to a dinner table knife,” says Teng Li, the senior author of the study and a materials scientist at the University of Maryland. Afterward, the hardened wood knife can be washed and reused, making it a promising alternative to steel, ceramic, and disposable plastic knives.

Li and his team also demonstrated that their material can be used to produce wooden nails as sharp as conventional steel nails. Unlike steel nails, the wooden nails the team developed are resistant to rusting. The researchers showed that these wooden nails could be used to hammer together three boards without any damage to the nail. In addition to knives and nails, Li hopes that, in the future, the material can also be used to make hardwood flooring that is more resistant to scratching and wear.

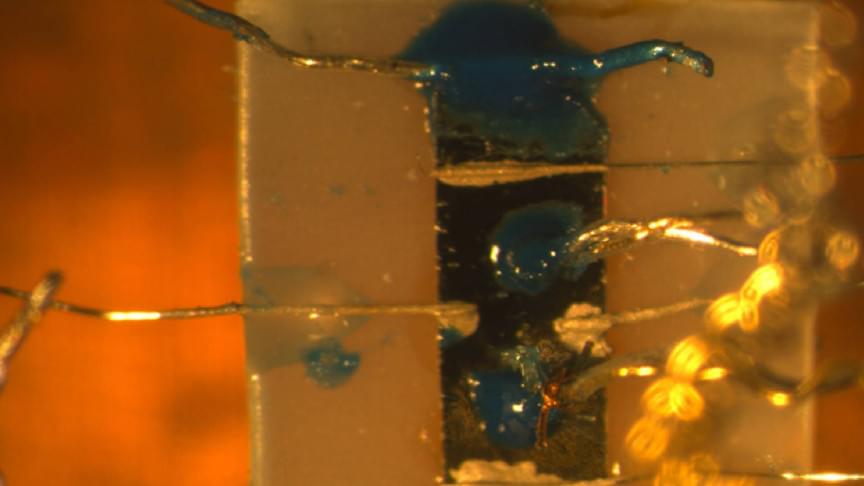

Scientists at Rice University have created a material that will protect steel from corrosion. In fact, it will also be flexible and heal itself when damaged.

This material will be used as a coating and is made from a lightweight sulfur-selenium alloy. It will be able to block moisture and chlorine-like zinc-and chromium-based coatings, protect steel under seawater-like conditions like polymer-based coatings, keep it from microbe-induced corrosion.

The experiments carried out before the results comprised putting small slabs of common mild steel coated with sulfur-selenium alloy in seawater for a month, along with an uncoated slab of steel as a control. The coated steel did not oxidize.

The iron-based superconductor material, Ba1−xKxFe2As2. Vadim Grinenko, Federico Caglieris/KTH Royal Institute of Technology

Twenty years ago, scientists first predicted electron quadruplets. Now, KTH Professor Egor Babaev, with the aid of international collaborators, has revealed evidence of fermion quadrupling in a series of experimental measurements on the iron-based material, Ba 1−x Kx Fe 2 As 2.

This is the first-ever experimental evidence of this quadrupling effect and the mechanism by which this state of matter occurs.

The supernova remanent is located about 19,600 light years away from Earth.

A new image by Chandra reveals a rare supernova remanent created by a white dwarf accumulating material from another star until it explodes.

Circa 2020

TOKYO — As scientists the world over scramble to develop a vaccine for the coronavirus, Kyushu University professor Takahiro Kusakabe and his team are working to develop a unique vaccine using silkworms.

In his project, each of the worms is a factory that manufactures a type of protein to serve as the key material for vaccine production. Kusakabe said it is possible to create an oral vaccine and aims to start clinical tests on humans in 2021.

In a building on the Kyushu University campus in Fukuoka, in western Japan, “we have about 250,000 silkworms in about 500 different phylogenies (family lines),” Kusakabe said.

Strongest and toughest glass known developed by McGill University scientists.

Scientists from McGill University develop stronger and tougher glass, inspired by the inner layer of mollusk shells. Instead of shattering upon impact, the new material has the resiliency of plastic and could be used to improve cell phone screens in the future, among other applications.

While techniques like tempering and laminating can help reinforce glass, they are costly and no longer work once the surface is damaged. “Until now there were trade-offs between high strength, toughness, and transparency. Our new material is not only three times stronger than the normal glass, but also more than five times more fracture-resistant,” says Allen Ehrlicher, an Associate Professor in the Department of Bioengineering at McGill University.