Circa 2013

When a material is damaged, you wouldn’t expect pulling it apart to suddenly make it less damaged. This counterintuitive effect is exactly what researchers at MIT observed in an experimental model recently, and it was so unexpected that the results had to be rechecked before anyone was ready to believe it. Astonishingly, it seems that under the right conditions, metal with small flaws and cracks can heal itself when tension is applied — if you pull it apart, it puts itself back together.

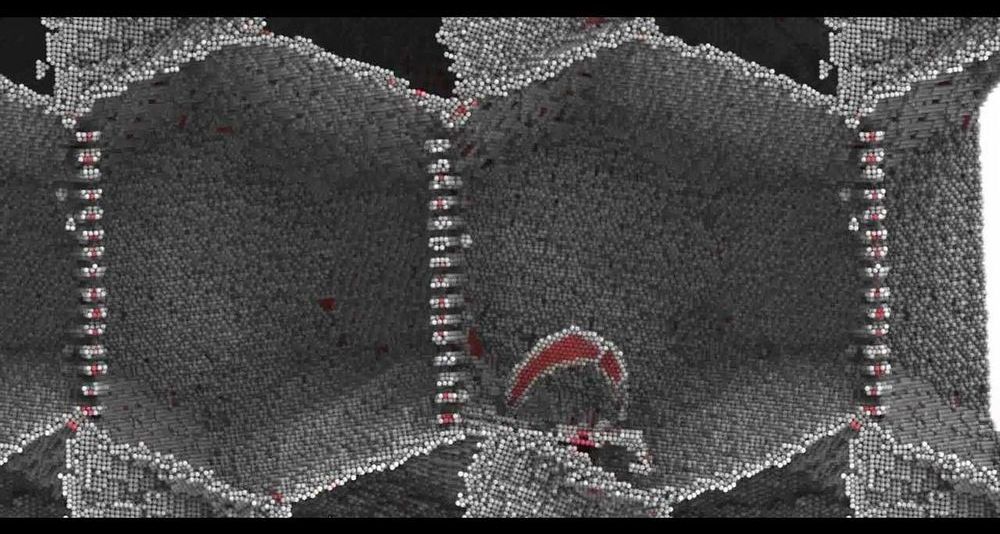

Researchers led by graduate student Guoqiang Xu and professor Michael Demkowicz modeled microscopic cracks in a sheet of nickel with tension applied. Instead of worsening, the cracks became smaller, then closed on their own as the edges fused together. After assuring themselves the effect was real, the next step was figuring out how it happens.

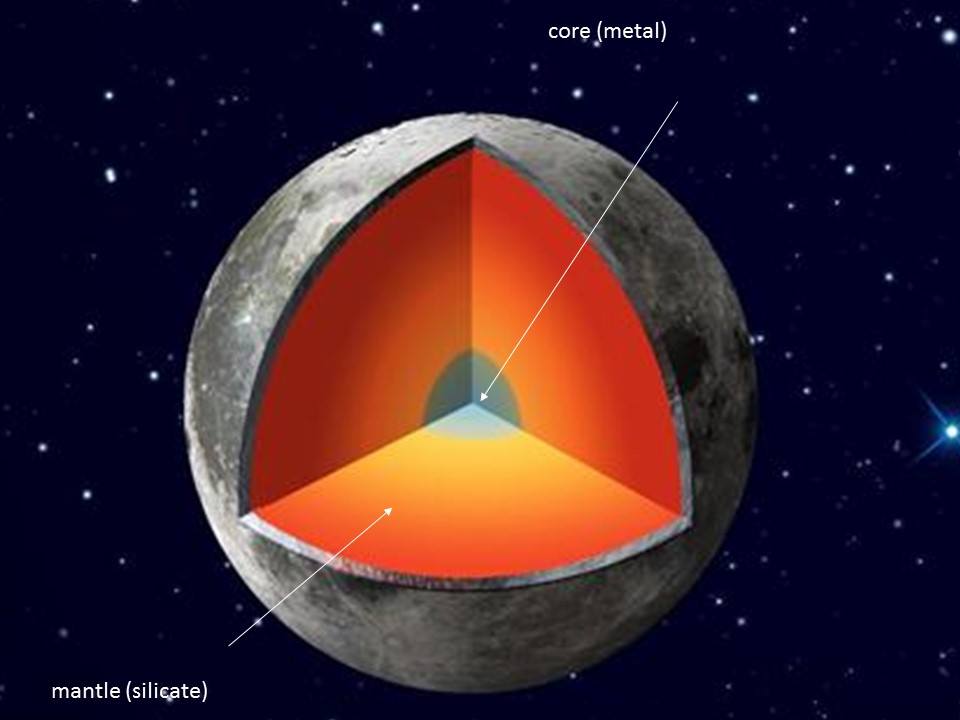

The answer has to do with the basic structure of metals, most of which are composed of microscopic crystalline grains of varying sizes and shapes. The orientation and size of these grains affects the overall mechanical strength and other characteristics of the material. Nickel is of particular interest because it is a basis for many so-called superalloys used in harsh environments like jet turbines, deep-sea oil rigs, and joints in heavy industrial equipment. It turns out that the grains making these materials so strong are not as static as scientists thought.