Scientists at ETH Zurich and IBM Research Zurich have developed a new technique that enables for the first time the manufacture of complexly structured tiny objects joining together microspheres. The objects have a size of just a few micrometres and are produced in a modular fashion, making it possible to program their design in such a way that each component exhibits different physical properties. After fabrication, it is also very simple to bring the micro-objects into solution. This makes the new technique substantially different from micro 3D printing technology. With most of today’s micro 3D printing technologies, objects can only be manufactured if they consist of a single material, have a uniform structure and are attached to a surface during production.

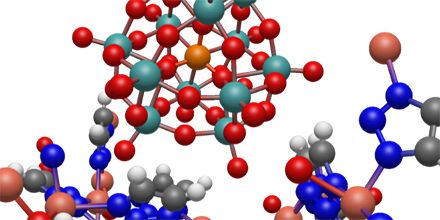

To prepare the micro-objects, the ETH and IBM researchers use tiny spheres made from a polymer or silica as their building blocks, each with a diameter of approximately one micrometre and different physical properties. The scientists are able to control the particles and arrange them in the geometry and sequence they like.

The structures that are formed occupy an interesting niche in the size scale: they are much larger than your typical chemical or biochemical molecules, but much smaller than typical objects in the macroscopic world. “Depending on the perspective, it’s possible to speak of giant molecules or micro-objects,” says Lucio Isa, Professor for Interfaces, Soft matter and Assembly at ETH Zurich. He headed the research project together with Heiko Wolf, a scientist at IBM Research. “So far, no scientist has succeeded in fully controlling the sequence of individual components when producing artificial molecules on the micro scale,” says Isa.