Space tourism … and much more.

Copyright ©2016 Parabolic Arc.

China’s big win.

Last week a team from Chinese 3D printing construction company WinSun visited Saudi Arabia, meeting with department of housing official and others to discuss the kingdom’s housing shortfall.

According to 3ders.com and others, the Chinese firm’s chairman and vice president met officials from the housing department and investment authority, and were told the Saudi government believes WinSun’s technology could help meet a shortage in available housing. WinSun was invited to open a Saudi factory.

According to an April report from Reuters, the Arab state is looking at a shortfall of 1.5 million housing units over the next five years.

WOW — now that’s an engineering feat.

While Dubai is keen to become a 3D printing world leader with their Dubai 3D Printing Strategy, they are by no means the only Middle Eastern nation to look into this technology. Last week a delegation of Chinese WinSun officials traveled to Riyadh, the capital of the Kingdom of Saudi Arabia, to discuss construction 3D printing. Among others, the Chinese construction 3D printing pioneers were invited to 3D print up to 1.5 million housing units over the next five years.

WinSun is the company that made construction 3D printing a practical reality. Back in 2014, the Shanghai-based company created headlines all over the internet for building not one, but ten 3D printed houses in less than 24 hours. Since then, Shanghai WinSun Decoration Design Engineering Co., to give its full name, has been building on that initial achievement with one 3D printed concrete creation after another. Back in March, they even unveiled two gorgeous 3D printed Chinese courtyards.

Growing up in Jakarta’s polluted slums, Vera Mulyani loved building things. As a child, she dreamed of becoming an architect.

More than two decades later, Mulyani is a self-proclaimed “Marschitect,” and spends her time brainstorming how human life might be sustained on the red planet. After studying at École d’Architecture de Nantes in France and at New York Film Academy, in January 2015 she founded Mars City Design, a think tank of sorts aimed at developing blueprints for the first self-sustaining city on Mars.

Earlier this month, Mars City Design raised $30,382 on Kickstarter to realize the next phase of its mission: Within the next three years, the group wants to 3D-print three to-scale habitat prototypes of Martian cities at Reaction Research Society’s test area in the Mojave Desert.

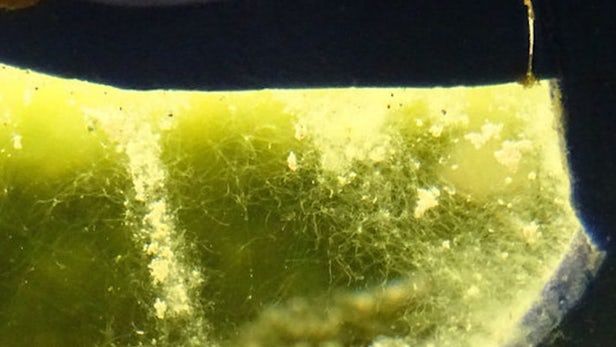

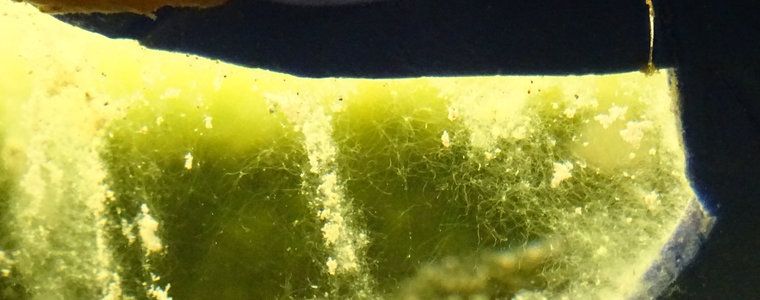

A lot of things are becoming “smart” these days, but bricks might not be something you’d expect to be added to the list. On the way to buildings that act like “large-scale living organisms,” scientists at the University of the West of England (UWE Bristol) are developing smart bricks that would make use of microbes to recycle wastewater, generate electricity and produce oxygen.

Microbial fuel cells (MFCs), which will be embedded in the bricks to give them their “smart” capabilities, have proven handy in the past, with researchers demonstrating how they can be used to generate electricity from human urine, dead flies or just plain old mud.

“Microbial fuel cells are energy transducers that exploit the metabolic activity of the constituent microbes to break down organic waste and generate electricity,” says Ioannis Ieropoulos, professor at UWE Bristol’s Robotics Laboratory. “This is a novel application for MFC modules to be made into actuating building blocks as part of wall structures. This will allow us to explore the possibility of treating household waste, generating useful levels of electricity, and have ‘active programmable’ walls within our living environments.”

Smart bricks capable of recycling wastewater and generating electricity from sunlight are being developed by a team of scientists from the University of the West of England (UWE Bristol). The bricks will be able to fit together and create ‘bioreactor walls’ which could then be incorporated in housing, public building and office spaces.

The UWE Bristol team is working on the smart technologies that will be integrated into the bricks in this pan European ‘Living Architecture’ (LIAR) project led by Newcastle University. The LIAR project brings together living architecture, computing and engineering to find a new way to tackle global sustainability issues.

The smart living bricks will be made from bio-reactors filled with microbial cells and algae. Designed to self-adapt to changing environmental conditions the smart bricks will monitor and modify air in the building and recognise occupants.

“An increasing number of US landowners want to build commune-style villages that are completely self-sufficient and have a low carbon footprint”