More energy efficient, high performance microprocessors on the way.

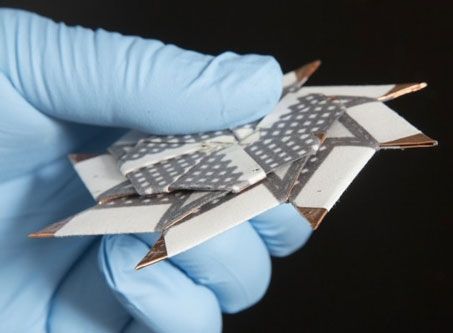

Abstract: Tiny high-performance lasers grown directly on silicon wafers solve a decades-old semiconductor industry challenge that, until now, has held back the integration of photonics with electronics on the silicon platform,

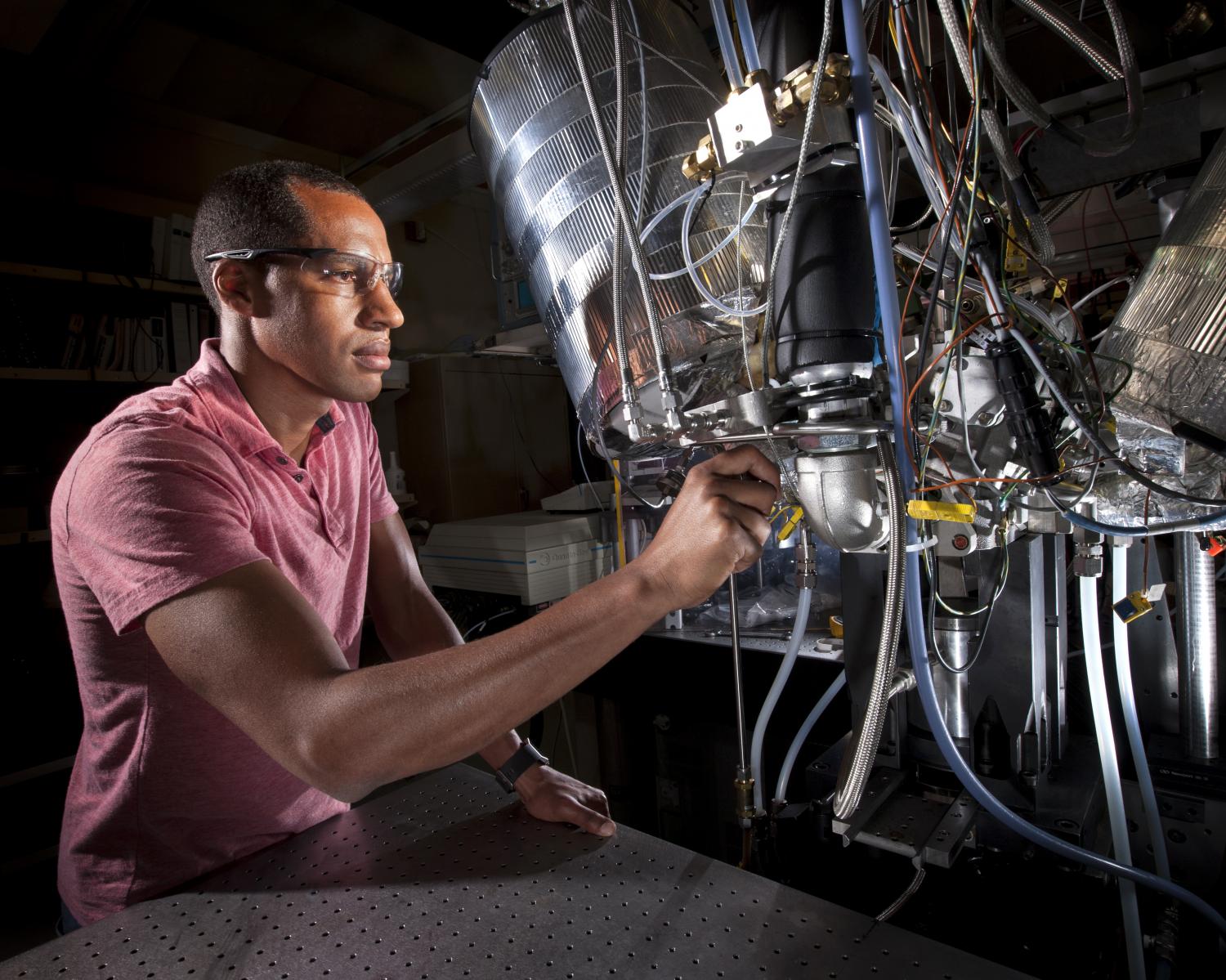

A group of scientists from Hong Kong University of Science and Technology; the University of California, Santa Barbara; Sandia National Laboratories and Harvard University were able to fabricate tiny lasers directly on silicon — a huge breakthrough for the semiconductor industry and well beyond.

For more than 30 years, the crystal lattice of silicon and of typical laser materials could not match up, making it impossible to integrate the two materials — until now.

Read more