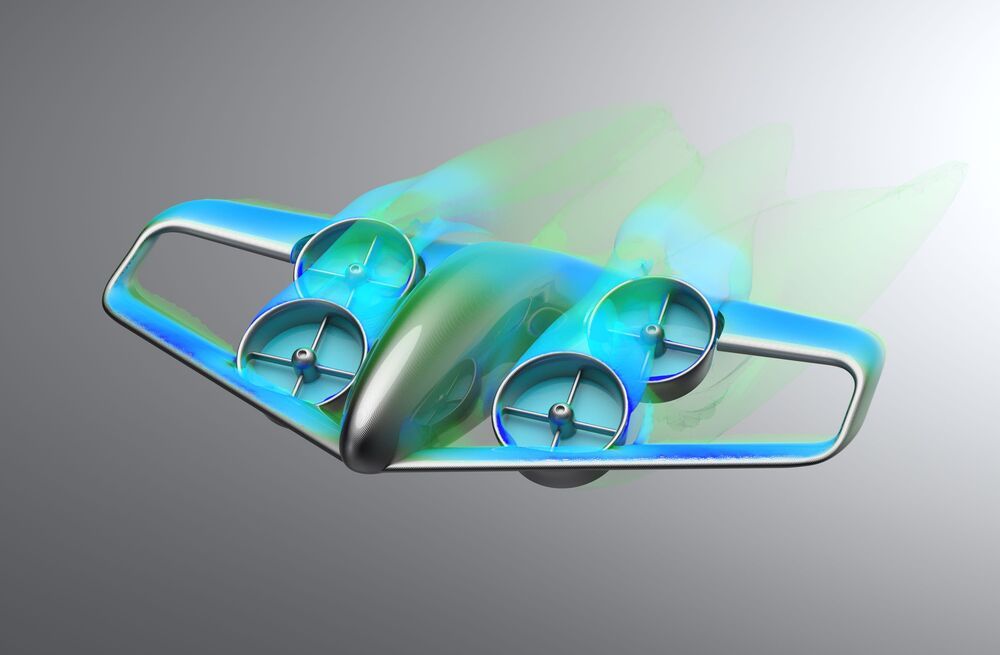

While a multitude of companies are jostling to compete in the emerging electric VTOL air taxi market, it’s very rare to find aircraft designs carrying more than five people. But British multinational giant GKN Aerospace is looking into something much bigger: “park ‘n’ ride” Skybus transports capable of carrying 30 to 50 passengers across congested parts of town, moving affordable public transport into the third dimension.

This initiative is part of the UK’s Future Flight Challenge, which is using some £125 million (US$171 million) of government cash and a further £175 million (US$239 million) from the industrial sector to fund a wide range of projects related to electric aviation, including drone swarm and delivery technologies, air traffic control that can handle a huge influx of autonomous drones and aircraft, eVTOL air taxis, sensor technologies, industrial inspection UAVs and other projects like the pop-up eVTOL airport in Coventry we wrote about yesterday.

Where most passenger-carrying eVTOL projects are envisaged as on-demand Uber-style services connecting individual passengers or small groups with ride-share services at either end, the Skybus project takes a public transport approach, with large birds ferrying significant numbers of people over city routes on fixed schedules.