Agree. So as a tech engineer, futurist, innovator, leader you have 3 key tracks to remain relevant in the future: bio/ living technology, quantum, and a hybrid of living/ bio meets quantum computing.

Editor s Note: Richard van Hooijdonk is a futurist and international keynote speaker on future technologies and disruption and how these technologies change our everyday lives. Van Hooijdonk and his international team research mega trends on digital health, robotic surgery, drones, the internet-of-things, 3D/4D printing, Big Data and other how new technologies affects many industries.

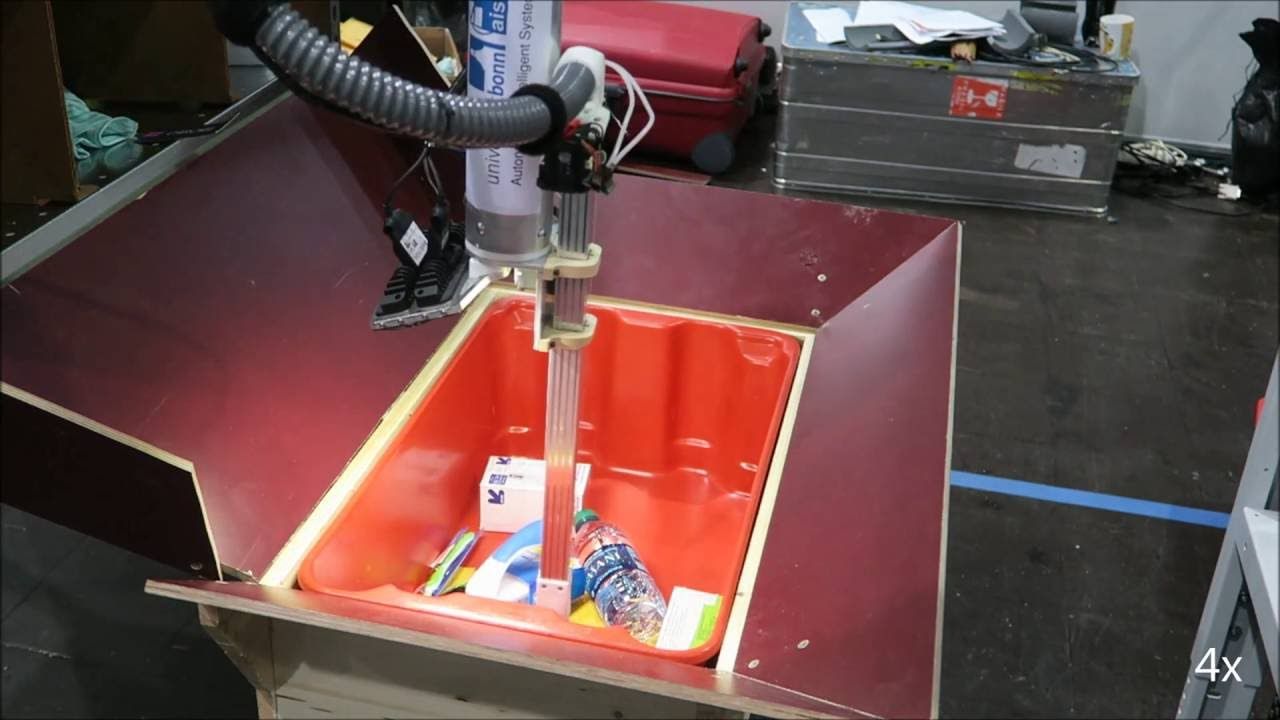

With people living increasingly longer lives, medical care from surgeons, physicians, pharmacists and dentists will increase as well. And since the future of healthcare will look very different from what it is today, the medical field may just be the right industry for you, even if being a doctor or nurse is not your calling. Many new technologies will be incorporated into the healthcare industry and we will see things like robotic surgeries and 3D-printed organ implants, to name a few. This means we will be seeing a whole new host of career opportunities, even for jobs that don t actually exist yet.

1. Healthcare Navigator Guides patients through the complex medical system of the future

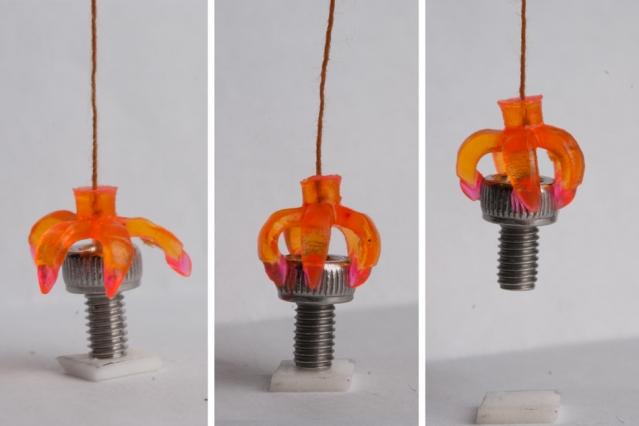

Being sick can be extremely stressful to yourself, the doctors and nursing staff. But your family and loved ones also have a lot to deal with when you are ill. Technology will make healthcare more and more complex to navigate in the future. We ll be introduced to bio-printers, electronic pills, 3D-printed medication, surgical robots and DNA manipulation. To make sense of all these new technologies and treatments, and guide the patient as well as family members, healthcare navigators will become indispensible.

Read more