AI paints a Picasso nude, just like Pablo did.

“Lost” Picasso nude comes out of hiding, thanks to artificial intelligence and 3D printing.

O,.o! Circa 2017

3D printers are useful devices for all kinds of reasons, but most have a critical weakness: they simply take a long time to actually make anything. That’s because additive manufacturing generally works by putting down an object one microscopic layer at a time. But a new holographic printing technique makes it possible to create the entire thing at once — in as little as a second or two.

Light-based 3D printing techniques generally use lasers to cause a layer of resin to harden in a pattern, but like extrusion printers, they have to do it layer by layer. If the laser shined all the way through the liquid resin, it would cause a big line of it to cure.

But what if you shined multiple weaker lasers through the resin, none of which was powerful enough to cure it except when they all intersected? That’s the technique developed by a team led by researchers at Lawrence Livermore National Laboratory.

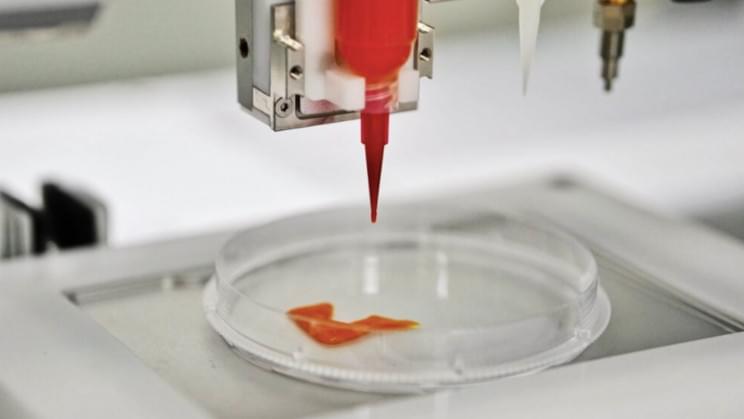

Leveraging 3D printing to make the meat appear more appetizing.

A biotech startup in China recently showcased its lab-grown pork and is aiming for cost-parity with conventionally sourced pork by 2,025 Reuters reported.

Amidst growing concerns of emissions resulting from meat production, countries are looking for protein alternates that can feed their population while also being eco-friendly. Plant-based meats have been around for a while but need further development to stand in as replacements to animal meats. Cultured or lab-grown meats are sourced from animal cells and show a high resemblance to conventional meat but lack production at scale and are expensive to manufacture, making it difficult for consumers to switch. 3D printing to make the meat appear more appetizing.

The volatile nature of space rocket engines means that many early prototypes end up embedded in dirt banks or decorating the tops of any trees that are unfortunate enough to neighbor testing sites. Unintended explosions are in fact so common that rocket scientists have come up with a euphemism for when it happens: rapid unscheduled disassembly, or RUD for short.

Every time a rocket engine blows up, the source of the failure needs to be found so that it can be fixed. A new and improved engine is then designed, manufactured, shipped to the test site and fired, and the cycle begins again — until the only disassembly taking place is of the slow, scheduled kind. Perfecting rocket engines in this way is one of the main sources of developmental delays in what is a rapidly expanding space industry.

Today, 3D printing technology, using heat-resistant metal alloys, is revolutionizing trial-and-error rocket development. Whole structures that would have previously required hundreds of distinct components can now be printed in a matter of days. This means you can expect to see many more rockets blowing into tiny pieces in the coming years, but the parts they’re actually made of are set to become larger and fewer as the private sector space race intensifies.

What do you think Chris Smedley.

⭐️ Join our Discord server! https://discord.gg/AYcSYdTBFG

🔴 YOU WANT TO SUPPORT THIS CHANNEL? 🔴

🤗 One-Time Donation?

- PayPal: https://paypal.me/JS2TheFuture.

- Bitcoin: bc1qv4lsfsplvfecrrgvmfclhga28we7mvh9563xdj.

🔗 Share the video with anyone who might be interested (it helps a ton!)

👍 Subscribe to our videos FOR FREE:

😏 Tired of YouTube? Then watch ALL our videos on Odysee: https://bit.ly/37yZEKY

CREDIT & A BIG THANK YOU TO:

🙏 Excellent music from Edgaras Žakevičius aka “Stellardrone”. He is an extremely talented musician who produces beautiful space ambient music for free.

🙏 Excellent music tracks from Harris Heller via Streambeats:

https://www.youtube.com/c/StreamBeatsbyHarrisHeller/videos.

🙏 SpaceXvision’s SpaceX animations & Patreon: https://www.patreon.com/SpaceXvision.

🚀 Interested in the Falcon rocket models in the background?

👉 Then go to Bohimso’s 3D printing Etsy-shop https://www.etsy.com/shop/Bohimso for the best Starship and also other spacecraft models!

Disclaimer: This video is purely our opinions and should not be regarded as financial advice. We are not financial advisors. This YouTube channel doesn’t give any recommendations to participate in stock trading, cryptocurrency trading or any other types of investments.

#JixuanSebastian #2theFuture #TheJSSpaceReport

Even though it’s now possible to 3D-print foods into millimeter-precise shapes and forms, cooking those printed foods is still a fairly inexact process. Scientists are trying to change that, by using lasers to cook foods to specific optimized standards.

Led by PhD student Jonathan Blutinger, a team at Columbia University started by pureeing raw chicken then extruding it through the nozzle of a 3D food printer, creating samples measuring 3 mm thick by about one square inch (645 sq mm) in area. They then precisely heated that chicken via pulses of either blue or near-infrared laser light, at wavelengths of 445 nanometers for the former and either 980 nanometers or 10.6 micrometers for the latter.

The laser moved across the meat in various trochoidal spiral patterns, with cooking times ranging from five to 14 minutes. An infrared camera continuously measured the surface temperature of the chicken, while eight embedded thermistors monitored its internal temperature.

⭐️ Join our Discord server! https://discord.gg/AYcSYdTBFG

🔴 YOU WANT TO SUPPORT THIS CHANNEL? 🔴

🤗 One-Time Donation?

- PayPal: https://paypal.me/JS2TheFuture.

- Bitcoin: bc1qv4lsfsplvfecrrgvmfclhga28we7mvh9563xdj.

🔗 Share the video with anyone who might be interested (it helps a ton!)

👍 Subscribe to our videos FOR FREE:

😏 Tired of YouTube? Then watch ALL our videos on Odysee: https://bit.ly/37yZEKY

CREDIT & A BIG THANK YOU TO:

🙏 Excellent music from Edgaras Žakevičius aka “Stellardrone”. He is an extremely talented musician who produces beautiful space ambient music for free.

🙏 Excellent music from Harris Heller via Streambeats:

https://www.youtube.com/channel/UCQ6hCusHlsIDXqoTbbTHSUQ

🚀 Interested in awesome SpaceX rocket models?

👉 Then go to Bohimso’s 3D printing Etsy-shop https://www.etsy.com/shop/Bohimso for the best Starship and also other spacecraft models!

Disclaimer: This video is purely our opinions.

#2theFuture #JixuanSebastian #TheJSSpaceReport

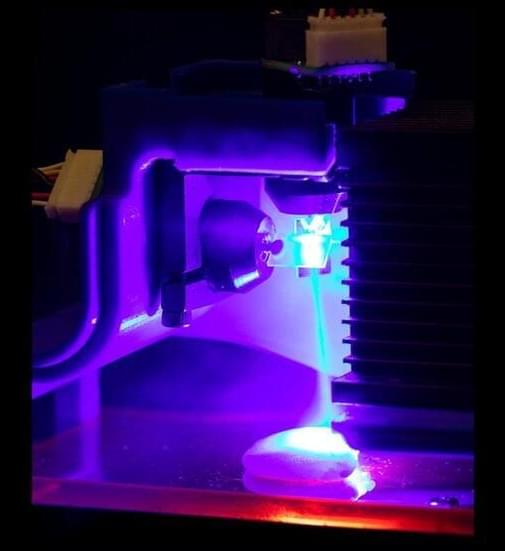

A team of researchers from Texas A&M University’s Department of Biomedical Engineering has designed and 3D bioprinted a highly realistic model of a blood vessel.

The model is made of a newly nanoengineered, purpose-built hydrogel bioink and closely mimics the natural vascular function of a real blood vessel, as well as its disease response. The team hopes its work can pave the way for advanced cardiovascular drug development, expediting treatment approval while eliminating the need for animal and human testing altogether.

“A remarkably unique characteristic of this nanoengineered bioink is that regardless of cell density, it demonstrates a high printability and ability to protect encapsulated cells against high shear forces in the bioprinting process,” said Akhilesh Gaharwar, associate professor at the university and co-author of the study. “Remarkably, 3D bioprinted cells maintain a healthy phenotype and remain viable for nearly one month post-fabrication.”