Soft robots are a class of robotic systems made of compliant materials and capable of safely adapting to complex environments. They have seen rapid growth recently and come in a variety of designs spanning multiple length scales, from meters to submicrometers.

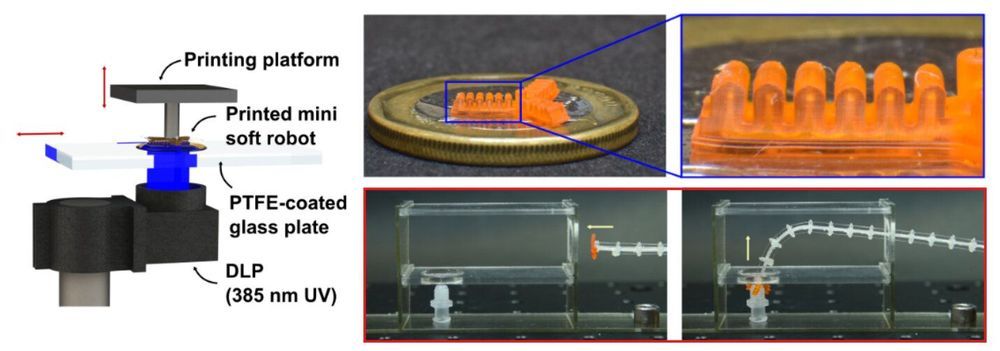

In particular, small soft robots at millimeter scale are of practical interest as they can be designed as a combination of miniature actuators simply driven by pneumatic pressure. They are also well suited for navigation in confined areas and manipulation of small objects.

However, scaling down soft pneumatic robots to millimeters results in finer features that are reduced by more than one order of magnitude. The design complexity of such robots demands great delicacy when they are fabricated with traditional processes such as molding and soft lithography. Although emerging 3D printing technologies like digital light processing (DLP) offer high theoretical resolutions, dealing with microscale voids and channels without causing clogging has still been challenging. Indeed, successful examples of 3D printing miniature soft pneumatic robots are rare.