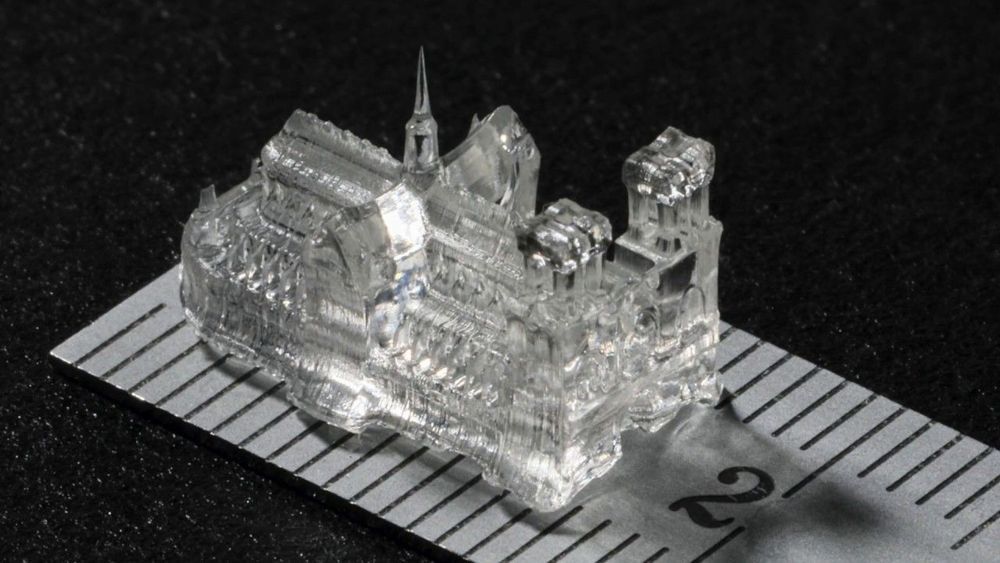

When you think of 3D printing, you probably imagine a structure being created layer by layer, from the bottom up. Now, researchers from Switzerland’s Ecole polytechnique fédérale de Lausanne (EPFL) say they have developed a completely new way of creating 3D objects that offer remarkable resolution “in record time.”

As EPFL News reports, the method draws on the principle of tomography — the technique for displaying a representation of a cross section through a solid object, using x-rays or ultrasound. To make an object, a photosensitive resin is illuminated from multiple angles, with the accumulation of light helping to solidify the resin. In other words, the object forms a solid structure within the resin in one go, rather than segment by segment, as is the case with traditional 3D printing.