Brian Krassenstein — 3dPrint

We all likely have realized by now that the rate of technological progress increases over time. For example, we will likely see as much progress in the next decade as we have in the last 30 years combined. This accelerating rate of development in technology ultimately will equate to a world alien to most of us, likely within many of our lifetimes.

There are few areas, if any, in which technology is developing faster than that of the 3D printing space. In the last several years alone we have gone from a society in which nearly no one had heard of the phrase ‘3D printing’ to one where it’s almost impossible to go a couple of days without hearing about it in one form or another.

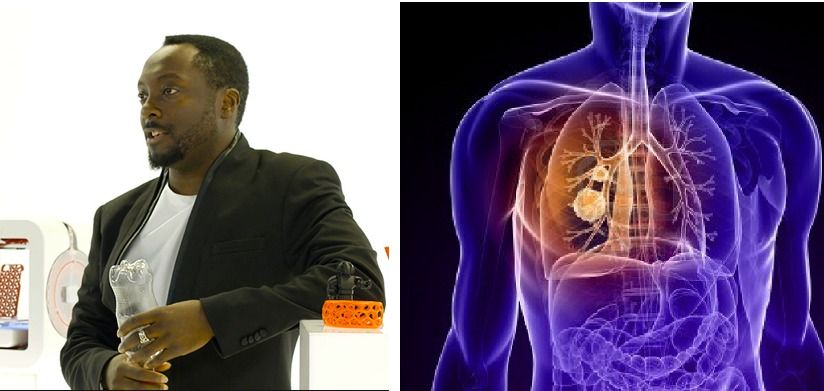

So you may now be wondering just how quickly 3D printing will develop over the next few decades. Will we be 3D printing organs for transplantation? How about 3D printing street legal cars or even airplanes? How about entire living organisms? Okay, wait, what did I just say?

Read more