Method combines quantum mechanics with machine learning to accurately predict oxide reactions at high temperatures when no experimental data is available; could be used to design clean carbon-neutral processes for steel production and metal recycling.

Extracting metals from oxides at high temperatures is essential not only for producing metals such as steel but also for recycling. Because current extraction processes are very carbon-intensive, emitting large quantities of greenhouse gases, researchers have been exploring new approaches to developing “greener” processes. This work has been especially challenging to do in the lab because it requires costly reactors. Building and running computer simulations would be an alternative, but currently there is no computational method that can accurately predict oxide reactions at high temperatures when no experimental data is available.

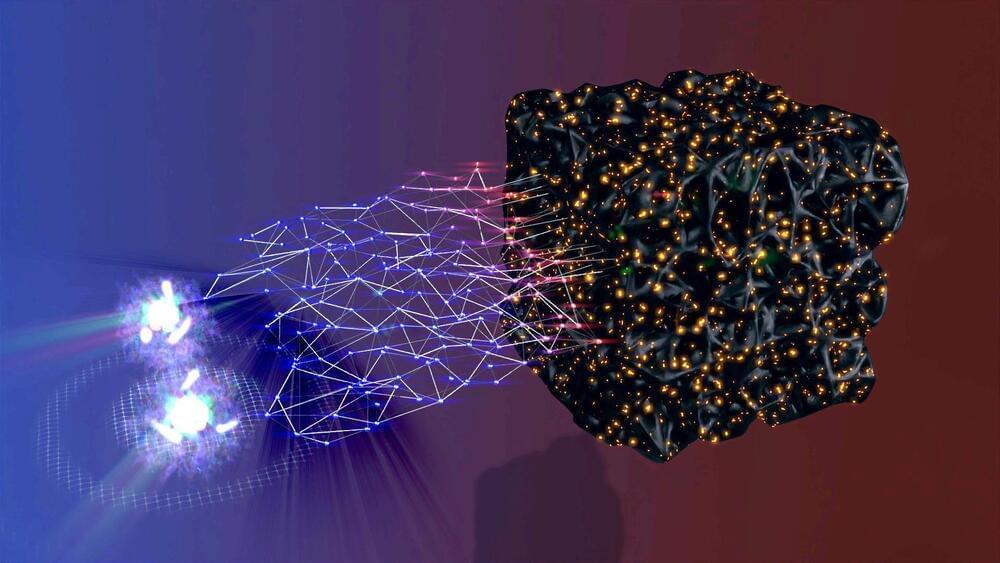

A Columbia Engineering team reports that they have developed a new computation technique that, through combining quantum mechanics and machine learning, can accurately predict the reduction temperature of metal oxides to their base metals. Their approach is computationally as efficient as conventional calculations at zero temperature and, in their tests, more accurate than computationally demanding simulations of temperature effects using quantum chemistry methods. The study, led by Alexander Urban, assistant professor of chemical engineering, was published on December 1, 2021 by Nature Communications.