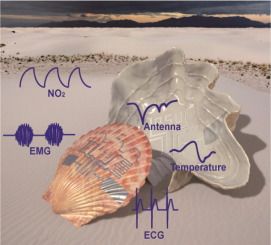

Deployment of functional circuits on a 3D freeform surface is of significant interest to wearable devices on curvilinear skin/tissue surfaces or smart Internet-of-Things with sensors on 3D objects. Here we present a new fabrication strategy that can directly print functional circuits either transient or long-lasting onto freeform surfaces by intense pulsed light-induced mass transfer of zinc nanoparticles (Zn NPs). The intense pulsed light can locally raise the temperature of Zn NPs to cause evaporation. Lamination of a kirigami-patterned soft semi-transparent polymer film with Zn NPs conforming to a 3D surface results in condensation of Zn NPs to form conductive yet degradable Zn patterns onto a 3D freeform surface for constructing transient electronics. Immersing the Zn patterns into a copper sulfate or silver nitrate solution can further convert the transient device to a long-lasting device with copper or silver. Functional circuits with integrated sensors and a wireless communication component on 3D glass beakers and seashells with complex surface geometries demonstrate the viability of this manufacturing strategy.