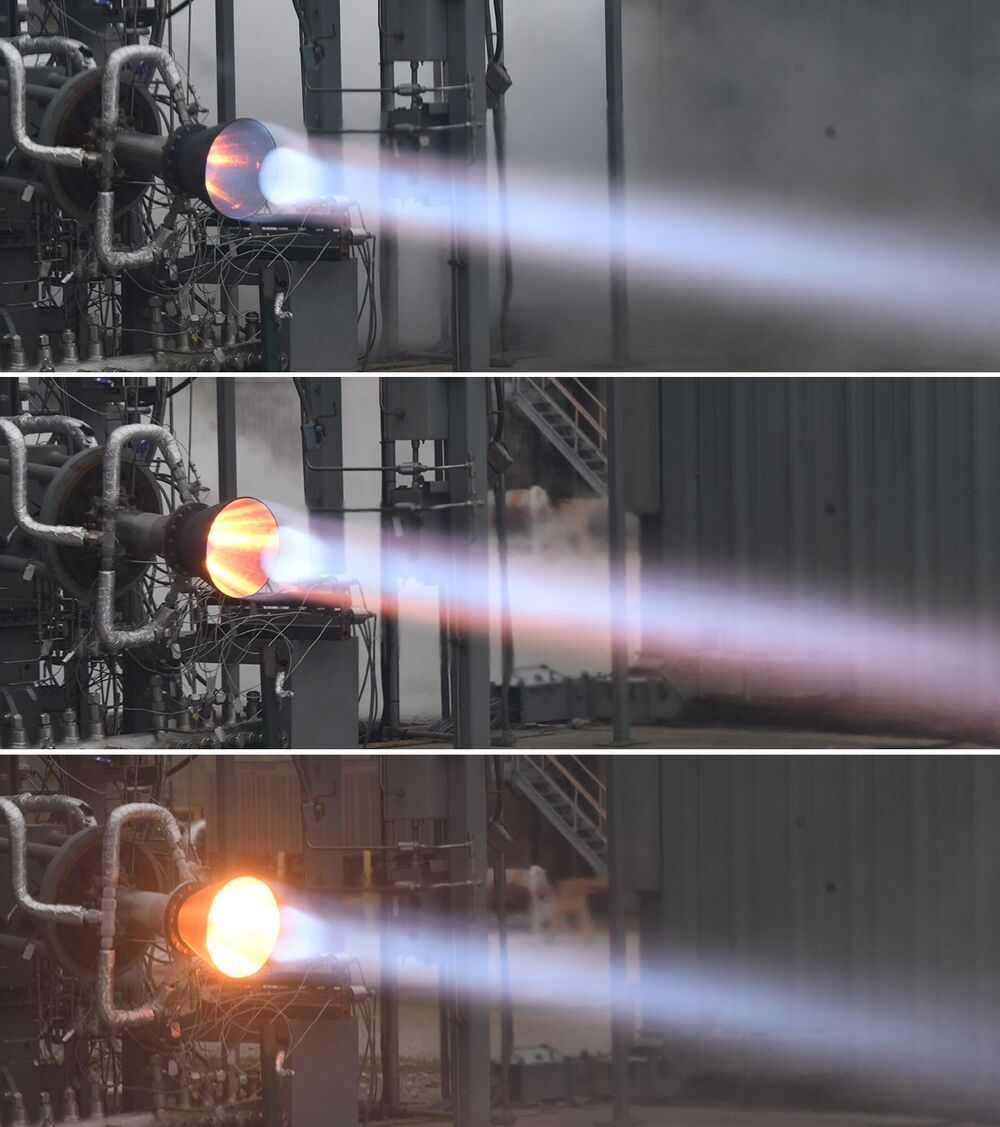

3D-printed parts can make rocket engines lighter, less expensive and more efficient.

At Marshall, we’re working with our industry partners to test the latest advances in additive manufacturing technologies:

NASA is partnering with Aerojet Rocketdyne to advance 3D printing technologies, known as metal additive manufacturing, and its capabilities for liquid rocket engines in landers and on-orbit stages/spacecraft.